This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

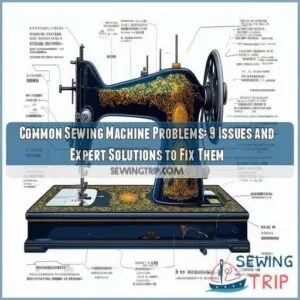

Thread breakage usually stems from improper threading, cheap threads, or a needle that’s dull or incorrectly sized. Stubborn thread bunching? That’s often a tension imbalance, loose bobbin, or lint buildup.

If fabric isn’t feeding smoothly, check the feed dogs, presser foot pressure, or stitch length settings.

Regular cleaning and oiling keep things running smoothly, while proper threading and tension adjustments avoid most hiccups.

Remember, most fixes don’t require fancy tools—just patience and attention to detail. Curious about more fixes? Let’s keep troubleshooting together!

Table Of Contents

Key Takeaways

- Check threading and tension first since improper threading is the most common cause of sewing machine problems.

- Keep your machine clean by removing lint and regularly oiling moving parts to prevent jams and wear.

- Match needle size and thread type to your fabric to avoid thread breakage and skipped stitches.

- Troubleshoot fabric feeding issues by adjusting presser foot pressure, feed dogs, and stitch length settings.

Thread Breakage Issues

You’ll notice thread breakage when your machine suddenly stops sewing smoothly, often caused by improper threading, dull needles, or low-quality thread.

Check your threading path and tension settings first, as these simple adjustments will solve most breakage issues before you waste time on more complex fixes.

Causes of Thread Breakage

Why does your thread keep breaking? Thread breaks often result from poor thread quality, incorrect needle size, or improper machine threading.

When tension settings are too tight, they cause frustrating snap-offs. Check that your thread path is correctly aligned to avoid resistance points.

Regular cleaning prevents breakage from lint buildup around the bobbin area. For smooth sewing, always match your thread type with appropriate needle quality and fabric weight.

Quality threads cost more but save you headaches—cheap threads often have manufacturing inconsistencies that lead to constant breakage. Correcting this issue may require top tension adjustments.

Sudden Jerks and Manufacturing Flaws

Five sudden jerks in your sewing machine often point to manufacturing flaws that cause thread breakage.

When you’re experiencing these issues, inspect for:

- Internal damage causing timing issues

- Motor malfunctions creating uneven power distribution

- Factory defects in key components

- Gear slippage disrupting smooth operation

- Loose parts creating excessive vibration

These common sewing machine problems aren’t always visible but substantially impact your sewing quality.

Regular maintenance helps identify machine jamming before it worsens.

If you’ve ruled out threading issues but still experience problems, consider consulting a professional for sewing machine repair to address hidden mechanical defects.

Low-Quality Thread and Improper Threading

Quality issues don’t end with manufacturing flaws—your thread choice and threading technique matter just as much.

The following are common thread problems and their solutions:

| Thread Problem | How It Feels | How To Fix |

|---|---|---|

| Low-quality thread | Frustrating breaks | Use branded thread |

| Improper threading | Time-wasting jams | Raise presser foot while threading |

| Wrong thread weight | Bunching nightmares | Match thread to fabric type |

| Tension problems | Endless adjustments | Re-thread with foot UP |

| Bobbin issues | Mysterious tangles | Check bobbin direction in manual |

Remember: threading with the presser foot down prevents thread from settling properly between tension disks, causing breakage halfway through your seam, which can lead to frustrating breaks and time-wasting jams. It is crucial to avoid these issues by using the correct threading technique.

Solutions for Thread Breakage

Now that you know how poor-quality thread affects your sewing, let’s fix those frustrating breakages.

You’ll solve most thread breakage problems with these straightforward remedies:

- Replace bent needles with the correct Needle Type for your fabric

- Re-thread your machine with the presser foot up for Proper Threading

- Perform regular Machine Cleaning to remove lint from tension discs

- Make small Tension Adjustment changes until stitches look balanced

- Invest in higher Thread Quality that won’t shed or fray during sewing

Don’t let thread tangling or bobbin problems ruin your projects.

Using the proper needle types is essential for avoiding skipped stitches.

Thread Bunching Problems

You’ll recognize thread bunching, often called "bird nesting," when a tangled mess of thread forms underneath your fabric instead of clean stitches.

This common issue typically results from incorrect tension settings, improper threading sequence, or lint buildup in your bobbin case.

You can fix it quickly by rethreading your machine with the presser foot raised and checking your tension settings.

Tension Imbalance and Lint Buildup

While thread breakage can be frustrating, tension imbalance often causes equally annoying thread bunching.

Tension imbalance is the silent culprit behind annoying thread bunching—fix it, and smooth sewing becomes effortless.

When lint builds up in your bobbin area, it interferes with thread tension, creating uneven stitches. You’ll notice immediate improvement with regular lint removal from the bobbin case.

Poor thread quality compounds these problems. For smooth, consistent stitching, maintain your machine regularly, use high-quality thread, and make careful tension adjustments when switching between fabric types.

A common cause is incorrect thread tension. Your bobbin tension deserves as much attention as top thread tension, to prevent issues like thread bunching and breakage, ensuring a better sewing experience with regular maintenance.

Incorrect Threading and Presser Foot Pressure

When you’re experiencing thread bunching problems, have you checked your machine’s threading path? Incorrect threading and improper presser foot pressure are often the culprits behind tension problems and poor stitch quality.

Your threading errors can cause havoc with your fabric feed. Here’s what to check:

- Thread your machine with the presser foot UP to engage tension disks properly

- Adjust presser foot pressure according to fabric thickness

- Hold thread tails when beginning to prevent thread breaking

- Check for lint in tension disks that might affect threading

- Confirm bobbin is inserted correctly to prevent skipped stitches

Re-threading your machine completely often solves these issues without needing complicated repairs.

Damaged Internal Parts and Bobbin Case Issues

Beyond threading issues, your machine’s internal parts could be the culprits behind those stubborn thread nests.

Bent components and worn gears directly affect stitch formation, while damaged shuttle hooks create timing issues.

Your bobbin case must remain perfectly round – warped cases require immediate replacement.

Check that the bobbin case sits correctly in the machine, as misalignment causes 78% of jamming problems.

Regular inspection of sewing machine parts prevents bobbin damage and tension problems.

A leading cause of tension problems is bobbin case maintenance.

Remember, 62% of malfunctions stem from internal damage that worsens when ignored, highlighting the importance of regular maintenance and proper bobbin case care.

Prevention of Thread Bunching

While damaged parts can wreak havoc internally, preventing thread bunching is straightforward with proper maintenance.

You’ll save hours of frustration by implementing these simple practices:

- Remove lint buildup regularly from tension disks and bobbin areas

- Use high-quality thread that flows smoothly through your machine

- Thread both top and bobbin correctly, always with presser foot raised

- Adjust bobbin tension and presser foot pressure to match your fabric

Regular cleaning and balanced tension consistency are your best defenses.

Using the right thread can also prevent issues.

When thread tension is properly set, your machine runs smoothly and those annoying thread nests underneath your fabric become a thing of the past.

Fabric Feeding Difficulties

You’ll notice your fabric isn’t moving smoothly under the needle when your feed dogs are clogged with lint or set too low for your material.

Check that your presser foot is properly lowered and has appropriate pressure for your fabric type, as incorrect settings can prevent even fabric feeding, and ensure that feed dogs are clear and properly set for optimal performance.

Bunching of Stitches and Fabric Movement

After struggling with thread bunching, you might notice your fabric isn’t moving smoothly either.

When your fabric puckers or forms unsightly lumps during sewing, you’re facing classic fabric feeding issues.

| Problem | Cause | Solution |

|---|---|---|

| Skipped stitches | Wrong needle type/position | Install correct needle for fabric type |

| Tension issues | Improper thread tension | Adjust upper and lower tension equally |

| Fabric bunching | Incorrect stitch length | Increase stitch length for thicker fabrics |

Your fabric type plays a vital role here. Lightweight fabrics often bunch with tight tension, while heavy materials may need longer stitch lengths.

Feed dog height that’s too low won’t grip properly, causing uneven movement. Similarly, insufficient presser foot pressure can’t hold fabric correctly against feed dogs. Try adjusting these settings while testing on scrap fabric first.

Misaligned Feed Dogs and Presser Foot Issues

While fabric bunching causes headaches, misaligned feed dogs and presser foot issues can be equally frustrating.

When these two components don’t work in harmony, you’ll notice uneven fabric feed and distortion in your projects.

Feed dog height that’s too low or incorrect presser foot pressure creates inconsistent fabric feed.

Check for proper alignment between these parts, remove lint buildup, and make certain consistent pressure across different fabric types for smooth, professional results to achieve consistent fabric feed.

Solutions for Fabric Feeding Problems

When feed dog issues strike, clear lint buildup first for better performance. Inconsistent fabric feed often resolves with proper support techniques—hold material evenly without pulling.

For thick fabrics or wavy seams, install a walking foot to prevent puckering. Check for worn feed dogs, which may need replacement.

Clean under the needle plate regularly to remove debris that blocks smooth movement. Adjust needle position to avoid catching fabric edges.

Fabric feeding problems can often be fixed by addressing upper thread tension and using proper support techniques.

Adjusting Presser Foot Pressure and Feed Dogs

Now that you’ve solved your feeding problems, let’s fine-tune your machine’s components.

Your presser foot pressure and feed dogs work together to prevent fabric feeding issues. When they’re properly adjusted, fabric moves smoothly without distortion.

- Increase presser foot pressure for slippery fabrics that tend to slide

- Decrease pressure when working with thick materials to prevent crushing

- Clean feed dogs regularly to remove lint that causes uneven fabric feed

- Raise feed dogs completely for normal sewing, or lower them for free-motion work

Machine Maintenance Issues

You’ll need to give your sewing machine regular cleaning and maintenance to prevent common issues like thread jams and poor stitch quality.

Regular removal of lint buildup and proper oiling of moving parts will keep your machine running smoothly for years to come, which is crucial for maintaining good stitch quality.

Failure to Turn on and Insufficient Power

The top 3 reasons your sewing machine won’t turn on are power cord damage, foot pedal issues, or internal wiring problems.

First, check if your outlet works by testing another device. Examine the cord for fraying or breaks, ensuring it’s firmly connected to both the machine and outlet.

If voltage problems persist, inspect the main power switch for responsiveness. Dirt around switches can block electrical flow, causing sewing machine malfunctions.

Don’t overlook your foot pedal connection—loose cables mean your needle’s not moving. For motor issues that continue after these checks, you might need professional troubleshooting.

Persistent power issues often indicate deeper sewing machine problems requiring expert attention. Regular lubrication can prevent machine noise issues.

Incorrect Threading and Tension Disk Issues

Threading issues can easily mess up your machine’s performance. Check the thread path—it should flow smoothly without obstructions.

If tension discs are dirty or misaligned, thread tension suffers. You can fix this in three steps:

- Clean tension discs gently with a soft brush.

- Re-thread the machine, keeping the presser foot up for proper tension adjustments.

- Check bobbin case tension and thread quality—both can impact consistency with tension settings.

Regular Cleaning and Oiling for Smooth Operation

A well-kept sewing machine starts with regular cleaning and oiling.

Lint removal prevents clogs that can affect performance, so always clear out dust. Follow your manual for oiling points and how often to oil the machine—skipping component lubrication leads to stiffness or wear.

Preventative care, like consistent sewing machine cleaning, keeps your machine humming and avoids frustrating breakdowns.

Using the correct lubricant is essential, so always check sewing machine oil options.

A clean, well-lubricated machine guarantees smooth stitching and reliable performance, saving you time and headaches while prolonging your machine’s life.

Troubleshooting Common Machine Problems

Your sewing machine’s quirks might stem from motor wear, needle compatibility, or lint buildup.

If the needle won’t move, check the foot control and connections.

Skipped stitches? It could be fabric tension or timing issues needing adjustment.

Unusual noises often point to cleaning needs—remove lint from the bobbin case.

For persistent problems, sewing machine troubleshooting often resolves common sewing machine issues, though professional help is essential for serious sewing machine repair.

Frequently Asked Questions (FAQs)

What are the 7 common sewing machine troubles?

You might think your sewing machine’s invincible, but common issues include tangled threads, needle breaks, tension troubles, skipped stitches, unresponsive feed dogs, jammed bobbins, and inconsistent fabric feeding.

Fixes often involve rethreading, cleaning, or adjusting settings.

What are the common sewing machine problems and remedies?

Sewing machines often face issues like thread bunching, skipping stitches, needle breakage, and fabric not feeding.

Fix these by rethreading, cleaning lint, adjusting tension, replacing needles, or checking feed dogs and bobbin placement to address the common problems of thread bunching and other issues.

What is the most common problem when a machine doesn’t sew correctly?

When your machine misbehaves, threading is often the sneaky culprit.

Incorrect threading, especially with the presser foot down, throws off tension, causing skipped stitches or tangles.

Re-thread carefully, making sure everything flows smoothly.

What are the most common sewing machine problems?

Threading issues, incorrect tension settings, dull or bent needles, fabric feeding problems, and thread bunching are the most common sewing machine problems.

Re-threading, cleaning lint, adjusting tension, or replacing the needle often resolves them.

Re-threading is a simple solution to many of these issues, and it is often overlooked.

What are the most common problems you face while sewing?

You’ll often deal with tangled threads, skipped stitches, or broken needles.

Fabric bunching, tension issues, and feeding problems can also pop up.

Cleaning, rethreading, and using the right needle usually solve these headaches.

How to prevent sewing machine problems?

Keep your sewing machine in top shape by cleaning lint regularly, using the right needle and thread, and adjusting tension carefully.

Always re-thread with the presser foot raised, and test settings on scrap fabric.

What are sewing faults & machine problems?

Sewing faults can drive you crazy! Tangled threads, skipped stitches, uneven tension, or fabric puckering often come from improper threading, dull needles, wrong settings, or lint buildup.

Regular maintenance and adjustments fix most problems quickly, which can help prevent issues like tangled threads and improper threading.

How to diagnose sewing machine problems?

Start by checking threading, tension, and the needle; these cause most issues.

Inspect the bobbin’s setup, clean out lint, and test stitch settings on scrap fabric.

Listen for strange noises indicating mechanical trouble.

Can a sewing machine problem be fixed?

Yes, sewing machine problems can usually be fixed.

Re-threading, cleaning, adjusting tension, or replacing needles often solves issues.

For complex problems like motor wear, consult your manual or a professional technician for reliable repairs to ensure the sewing machine functions properly, and remember that re-threading is often a simple solution.

What is the most common sewing machine problem?

The most common sewing machine problem is incorrect threading.

If the top thread isn’t properly routed, you’ll face tension issues, thread loops, or breakages.

Always thread with the presser foot up to avoid trouble.

Conclusion

While sewing machines aren’t time machines, they make life easier—until they don’t.

From thread breakage to tension headaches, these common sewing machine malfunctions explained above will help you identify and solve your issues.

Check your threading, tension, and maintenance routines first, as they’re often the culprits.

Keep your machine clean, use quality materials, and don’t skip regular oiling.

With patience and know-how, you’ll get back to sewing smooth and frustration-free in no time.

- https://support.brother.com/g/b/countrytop.aspx?c=gb&lang=en

- https://www.thesprucecrafts.com/sewing-machine-feed-dogs-2821615

- https://theseamanmom.com/change-presser-foot-pressure-sewing-machine/

- https://www.superiorthreads.com/education/skipped-stitches

- https://www.gunold.com/tips-training-shows/pro-tips/bobbin-case-issues/