This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Embarking on a denim sewing project can feel like conquering Everest—daunting yet thrilling. You’re not just making clothes; you’re crafting a statement, a piece of art that’s as tough and timeless as the fabric itself.

Embarking on a denim sewing project can feel like conquering Everest—daunting yet thrilling. You’re not just making clothes; you’re crafting a statement, a piece of art that’s as tough and timeless as the fabric itself.

Whether you’re dreaming of custom jeans or a chic denim jacket, mastering the art of sewing denim is key to turning those dreams into reality. This guide will arm you with essential tips for perfect jeans projects, from selecting the right needle and thread to mastering topstitching and tackling bulky seams.

Dive in, and let’s demystify the process of sewing denim, transforming you from a hopeful hobbyist into a denim deity.

Yes, you do need a special needle to sew denim. Denim needles, also known as Jeans needles, have a modified medium ball point and a reinforced blade to penetrate thick fabrics with minimal risk of breakage.

Table Of Contents

Key Takeaways

- Denim needles are essential for sewing denim, with sizes 90/14 recommended for light to medium-weight denim and 100/16 for heavy-weight denim to penetrate the fabric with minimal deflection and reduce the likelihood of needle breakage.

- Pre-treating denim by washing and drying it without detergent or bleach is crucial to prevent bleeding and shrinking, ensuring the fabric is ready for cutting and sewing.

- Using the correct thread and stitch length is important when sewing denim; all-purpose polyester thread for construction, upholstery, or topstitching thread for topstitching, and a stitch length of 3.0-4.0 mm are recommended for best results.

- Special techniques and tools can enhance sewing with denim, such as using a Jean-A-Ma-Jig or leveling foot for bulky seams, a mallet to flatten seams, and a roller or walking foot for even feeding of the fabric.

Thread and Stitch Considerations

When sewing denim, choosing the right thread and stitch settings is crucial for achieving professional-looking jeans projects. For seams, an all-purpose polyester thread is recommended, while topstitching requires a switch to upholstery or topstitching thread to handle the fabric’s thickness and provide durability.

Adjusting your stitch length is also important; a straight-stitch length between 3.0 mm and 4.0 mm is ideal for most denim thicknesses, and tension adjustments may be necessary to ensure smooth stitches.

These considerations are key to handling denim’s unique properties and achieving the best results in your sewing projects.

Thread Types for Seams and Topstitching

When sewing denim, choosing the right thread is crucial for both the seams and topstitching.

- Thread Thickness: Opt for a thicker thread for topstitching to achieve that classic denim look. For seams, a standard all-purpose thread works well.

- Thread Fiber: Polyester thread is strong and durable, making it ideal for sewing denim. It can handle the stress of denim’s weight and wear.

- Bobbin Thread: Use a regular weight (50 wt.) thread in the bobbin to ensure smooth sewing and to avoid tension issues.

- Topstitching Contrast: For a striking contrast, choose a topstitching thread in a traditional gold or tan color. This adds visual interest and professional finish to your denim projects.

- Zigzag Stitch: When working with stretch denim, use a narrow zigzag stitch to allow the seam to stretch with the fabric, preventing popped stitches.

These tips will help you master denim sewing, whether you’re making jeans, jackets, or accessories.

Stitch Length for Denim

When sewing denim, it’s crucial to adjust your stitch length. For sturdy denim fabric, a longer stitch length of 3-4 mm yields the best results. This is especially important when working with thick seams or multiple layers of fabric.

A quality thread is essential for durability, and using topstitching needles can enhance the appearance of your denim garments. For stretch denim, consider using a stretch stitch or interfacing types that accommodate the fabric’s give.

A denim needle is specifically designed to handle the rigors of sewing thick fabrics, ensuring minimal deflection and a smoother sewing experience. Remember, the right combination of a longer stitch, quality thread, and appropriate needles will elevate your denim projects.

Tension Adjustments

When sewing denim, tension adjustments are crucial to accommodate the thick fabrics and heavy threads typically used.

- Match the needle size to your denim’s thickness; use jeans needles for heavy wovens.

- Adjust your machine’s tension to work with different thread weights; higher tension may be needed for topstitching.

- Calibrate your machine if stitches appear uneven; test on scraps to find the ideal setting.

Cutting and Preparing Denim

Before you start sewing your denim project, it’s crucial to properly prepare your fabric. Make sure to pretreat your denim by washing and drying it, which will prevent any future shrinkage.

When cutting, pay attention to the weight of your denim and use the appropriate techniques for light, medium, or heavyweight fabrics.

Pretreating Denim Fabric

When you’re ready to tackle a denim project, pretreating your fabric is a crucial first step. Begin by washing and drying your denim without detergent or bleach to remove sizing and preshrink the fabric.

This step softens the fibers, ensuring your finished piece won’t shrink or warp after its first wash.

For cutting, always use sharp scissors to ensure clean edges. If you encounter bulky seams while sewing, a small hammer can help flatten them, and a bumper or leveling foot can assist in keeping your stitches even.

When selecting needles, a universal needle is a versatile choice, but for denim, specifically, opt for a jeans needle to handle the fabric’s thickness. Remember, the right preparation leads to a smoother sewing experience and a more professional-looking final product.

Cutting Techniques for Different Weights

After pretreating your denim, it’s crucial to consider the weight of your fabric when cutting.

For light and medium-weight denim, you can cut on the fold, but for heavyweight denim, it’s best to cut flat to maintain accuracy.

Layout strategies are key; ensure proper grain orientation to avoid twisting in the final garment.

When sewing denim, go slow and use a mallet to flatten bulky seams. For interfacing options, fusible tricot is ideal for its flexibility.

Marking and Interfacing

When marking and interfacing your denim, precision is key for a professional finish. Use water-soluble pencils to clearly mark your cuts and folds, ensuring visibility against the fabric’s dark hue.

Opt for fusible tricot interfacing to maintain the denim’s natural stretch and movement, aligning it carefully with the grainline orientation.

To manage bulk, especially in seams and hems, consider the seam allowance width; wider allowances can be reduced for a cleaner look.

For DIY enthusiasts joining a jeans sewalong or tackling their own denim sewing guide, these steps are crucial. Remember, interfacing is your ally in areas prone to stress, like waistbands and buttonholes, providing extra stability where needed.

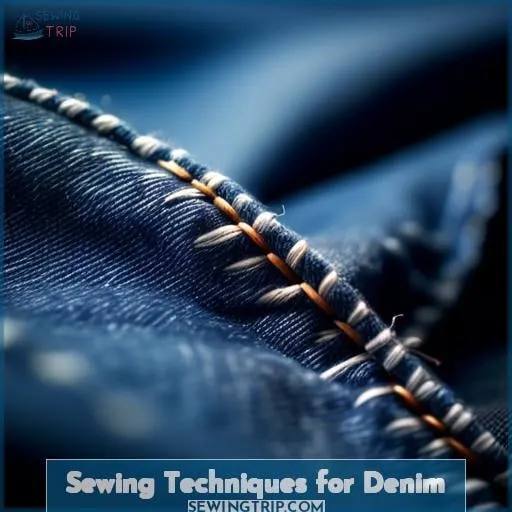

Sewing Techniques for Denim

When tackling denim projects, it’s crucial to use the right tools and techniques to ensure strong, professional-looking seams.

For sewing over bulky seams, tools like the Jean-A-Ma-Jig or a leveling foot can help your presser foot glide smoothly, preventing the machine from stalling or skipping stitches.

It’s important to use a denim needle, either size 90/14 for light to medium-weight denim or 100/16 for heavyweight denim, to penetrate the fabric effectively.

These tips will help you achieve even feeding and avoid common pitfalls like skipped stitches when sewing with this robust material.

Sewing Over Bulky Seams

When tackling denim projects, sewing over bulky seams can often feel like a daunting task. However, with the right approach and tools, you can achieve smooth, professional-looking results that will make your denim creations stand out.

- Denim scraps or leveling bumpers: Utilize these to balance your presser foot over uneven layers, ensuring smooth feeding and preventing skipped stitches.

- Handcrank the flywheel: For precise control over tough spots, manually turning the flywheel allows you to gently work through without breaking needles or damaging your fabric.

- Use a mallet to flatten seams: Before sewing, gently hammer down thick seams to reduce bulk. This simple step can significantly improve your machine’s ability to sew through multiple layers.

Using Tools for Even Feeding

When sewing denim, using the right tools can significantly enhance your sewing experience and the quality of your projects. Tools like the roller foot and walking foot are essential for achieving even feed when working with denim, a fabric known for its thickness and toughness.

These tools work in tandem with the machine’s feed dog and presser foot to ensure that the fabric moves smoothly under the needle, preventing issues like skipped stitches or uneven seams.

The roller foot, with its rollers that glide over the fabric, is particularly useful for navigating over bulky seams, such as those found in jeans hems. It allows for seamless sewing over thick layers without the foot getting stuck. On the other hand, the walking foot, equipped with its own set of feed dogs, grips the top layer of fabric.

This synchronizes with the machine’s feed dogs to move all layers of fabric evenly, making it invaluable for sewing multiple layers of heavy cloth like denim quilts or when matching patterns.

Both these tools are indispensable for denim sewing projects, ensuring that the fabric feeds through the machine evenly, resulting in professional-looking seams and topstitching. Whether you’re working on a simple denim repair or constructing a denim garment from scratch, incorporating a roller foot or walking foot can make a significant difference in the outcome of your sewing project.

Preventing Skipped Stitches

When sewing denim, preventing skipped stitches is crucial for achieving strong, durable seams. To avoid this common issue, start by selecting the right needle size, which should match the fabric thickness you’re working with.

A denim or jeans needle, typically size 90/14 for medium-weight denim or 100/16 for heavyweight, is designed to penetrate thick fabrics with minimal deflection.

Adjusting the tension is another key step. If the tension is too loose, you’ll end up with loops on the underside of your fabric; too tight, and the stitches may pucker or break. A general guideline is to increase the tension slightly from what you’d use for lighter fabrics, but the exact setting can vary based on your machine and the fabric’s thickness.

Test stitching on scraps of your denim can help you find the ideal tension setting.

Ensuring even feeding of the fabric through the machine is essential to prevent skipped stitches. Tools like a Jean-A-Ma-Jig or a leveling button (for machines that have one) can help the presser foot navigate over thick seams and maintain consistent stitch quality.

Additionally, adjusting the presser foot pressure according to the fabric’s thickness can improve feeding and prevent skipped stitches.

In summary, to prevent skipped stitches when sewing denim, use the appropriate needle size and type, adjust tension settings as needed, and ensure even fabric feeding with the help of specialized tools or machine adjustments.

These steps will help you achieve strong, professional-looking seams on your denim projects.

Finishing Denim Projects

When finishing your denim projects, it’s crucial to focus on pressing for crisp seams, managing bulk in hems, and selecting durable seam finishes.

Pressing with high heat and steam ensures your seams lay flat and look professional.

For bulky hems, techniques like using a Jean-A-Ma-Jig or hammering down the fabric can make sewing easier and more precise.

Lastly, choosing the right seam finish, such as flat-felled seams, adds durability and a high-end look to your denim creations.

These steps are essential for achieving a polished and long-lasting denim project.

Pressing for Crisp Seams

To achieve crisp seams when sewing denim, you’ll need to master your iron technique and make good use of pressing equipment.

Set your iron to a high-temperature cotton setting and apply plenty of steam. Use interfacing options wisely to stabilize areas that need it.

Manage your seam allowance carefully, ensuring it’s even and appropriate for the denim’s weight. Seam tools like a clapper can help set seams after pressing, especially for bulky areas.

A mallet can be used to flatten bulky seams before topstitching, ensuring a professional finish. Remember, pressing is different from ironing; it involves lifting and placing the iron down with pressure, rather than moving it across the fabric, which can stretch and distort the material.

Hemming Tips for Bulk Management

After pressing your denim for crisp seams, it’s time to tackle the hem. Hemming denim can be tricky due to the fabric’s bulk, but with the right techniques, you’ll achieve a professional finish.

- Fold Over: Begin by folding the hem allowance to the desired length. Use fusible interfacing to reinforce the fold and prevent stretching.

- Jean-A-Ma-Jig: As you sew, use a Jean-A-Ma-Jig or stacked Post-it notes to help the presser foot glide smoothly over the thick layers at the side seams.

- Clapper: After sewing, press the hem with steam and use a tailor’s clapper to flatten the bulk, ensuring a crisp edge that stays in place.

Choosing Seam Finishes for Durability

When choosing seam finishes for your denim projects, durability is key. Seam reinforcement is crucial, and flat felled seams are a robust option, adding strength and longevity to your garments.

Serged seams are also effective, especially for preventing fraying in heavy-duty fabrics like denim. Topstitching and decorative stitching not only enhance the appearance but also contribute to the seam’s durability.

For a professional look, consider using a serger to create clean finishes or a faux flat fell seam for a simpler approach. These techniques ensure your denim creations withstand wear and tear, looking great for years to come.

Frequently Asked Questions (FAQs)

How do I adjust my sewing machine’s tension when sewing denim to prevent puckering or skipped stitches?

To prevent puckering or skipped stitches when sewing denim, gradually increase your machine’s tension. Start at the normal setting (usually around 4) and test until the stitches appear even on both sides.

Can I use a twin needle for topstitching on denim, and if so, what adjustments should I make to my machine settings?

Yes, you can use a twin needle for topstitching on denim, turning your project into a runway masterpiece.

Ensure your machine is set for a twin needle to avoid mishaps.

Lengthen your stitch to 4mm for a crisp finish, and practice on scrap denim to perfect your technique.

What are the best practices for sewing over thick denim seams without breaking needles or damaging my sewing machine?

To sew thick denim seams without breaking needles or damaging your machine, use a denim needle. Hammer seams to soften. Sew slowly and handcrank over tough spots. Consider a Jean-A-Ma-Jig or hump jumper for level sewing.

How do I choose the right type of denim fabric for my project, considering factors like weight, stretch, and wash?

Choosing the right denim for your project is like navigating a maze; each turn (or choice) can lead you to a different outcome.

Consider weight, stretch, and wash. Lighter weights are ideal for shirts and dresses, while heavier denims suit jeans and jackets.

Stretch denim, with 1-4% elastane, offers comfort for fitted styles. Pre-washing is crucial to manage shrinkage and dye leaching.

Your project’s success hinges on these choices, ensuring your creation wears well over time.

When sewing stretch denim, how do I prevent the fabric from stretching out of shape, especially around seams and hems?

To prevent stretch denim from stretching out of shape, especially around seams and hems, use a narrow zigzag stitch or a stretch stitch.

For hems, consider using a twin needle for a professional finish that accommodates stretch.

Additionally, stabilizing the fabric with fusible interfacing in areas prone to stretching, like waistbands and buttonholes, can help maintain shape and structure.

Conclusion

Eureka! You’ve navigated the rugged terrain of sewing denim, armed with the know-how to select the right needle—yes, a special needle is indeed essential for tackling this durable fabric.

From pre-treating your denim to mastering the art of topstitching and managing bulky seams, you’re now equipped to transform that tough textile into wearable masterpieces.

Your denim projects, be they jeans or jackets, aren’t just clothes; they’re a statement of your skill and style.