This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

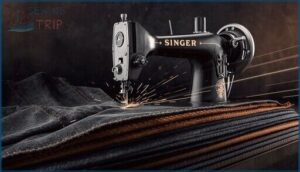

Your standard household machine stalls when you stack denim for reinforced seams or attempt canvas upholstery—the motor groans, the needle bends, and you’re left with skipped stitches and frustration.

A Singer sewing machine for heavy duty use solves that problem with a reinforced metal frame and a 90-watt motor that punches through multiple layers without hesitation. These machines maintain precision alignment at 1,100 stitches per minute, handling everything from leather belts to sailcloth with the same steady power.

You need equipment that matches your ambition—whether you’re building outdoor gear, repairing work jackets, or tackling upholstery projects that would break lighter models. The right heavy-duty Singer transforms challenging materials into controlled, professional results.

Table Of Contents

- Key Takeaways

- Key Features of Singer Heavy Duty Sewing Machines

- Top 10 Singer Heavy Duty Sewing Machines

- 1. Singer Heavy Duty Sewing Machine 4432

- 2. Heavy Duty Sewing Machine

- 3. SINGER Heavy Duty Sewing Machine 4423

- 4. Singer Heavy Duty Sewing Machine 4411

- 5. Singer Classic Heavy Duty Sewing Machine

- 6. Singer Heavy Duty Computerized Sewing Machine

- 7. Singer Heavy Duty Sewing Machine Kit

- 8. Singer M1000 Heavy Duty Sewing Machine

- 9. Singer Heavy Duty Sewing Machine

- 10. Singer Quantum Stylist Sewing Machine

- Comparing Mechanical Vs. Computerized Singer Models

- Choosing a Singer Heavy Duty Machine for Your Needs

- Maintenance Tips for Heavy Duty Singer Machines

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Singer heavy-duty machines use reinforced metal frames and 90-watt motors (60% stronger than standard models) to maintain precision alignment through thick materials like denim, leather, and canvas at speeds up to 1,100 stitches per minute.

- The key distinction between mechanical and computerized models lies in control philosophy: mechanical versions deliver hands-on mastery through physical dials with 25+ year lifespans, while computerized models offer 548-600 programmable stitch applications with LCD interfaces for complex pattern work.

- Motor power selection directly determines fabric compatibility—90W to 105W motors with at least 0.7 Nm torque handle genuine leather and multi-layer canvas, while proper needle sizing (70/10 for delicates up to 110/18 for heavy materials) prevents skipped stitches and extends machine longevity.

- Regular maintenance protocols—cleaning after every project, oiling every 8 hours of operation, and replacing needles every 6-8 hours—extend machine lifespan by 25% and maintain consistent performance on heavyweight fabrics that would stall consumer-grade equipment.

Key Features of Singer Heavy Duty Sewing Machines

Singer’s heavy-duty machines aren’t built like consumer models—they’re engineered to handle what would stall a standard machine.

You’ll find reinforced frames, motors that punch through multiple layers without hesitation, and components designed for years of consistent use.

These specific features separate a heavy-duty Singer from everything else in your sewing room.

Heavy-Duty Metal Frame and Build Quality

The metal frame inside your Singer heavy duty machine is your foundation for mastering thick fabrics—it’s what keeps alignment locked in during high-speed runs through denim and canvas. This rigid construction cuts vibration, prevents warping, and delivers lifespan metrics exceeding ten years with proper care. Build variants across models share the same durability philosophy:

- Heavy-duty metal frame maintains precision alignment for years

- Stainless-steel bed plate eliminates fabric snags and scratches

- Vibration reduction ensures stable sewing at 1,100 SPM

- Metal construction outlasts plastic competitors in durability testing

These machines also boast enhanced piercing power for multiple layers.

High-Speed Stitching and Motor Power

Your Singer heavy duty machine runs on a 90-watt motor—60% stronger than standard models—delivering 1,100 stitches per minute for rapid fabric penetration through denim, leather, and canvas. This power consumption stays efficient at 105 watts total, while speed control lets you dial from slow precision to full-throttle runs.

These motors also offer improved energy savings compared to older clutch motors. Motor efficiency translates directly to stitch accuracy on thick fabrics, giving you consistent seams without skipped stitches or jamming.

Adjustable Stitch Length and Width

Speed means nothing without precision control. Adjustable stitch length (0–4 mm) and width (up to 6 mm) on Singer HeavyDuty machines let you customize every seam for thick fabrics like denim or leather. You’ll see up to 20% stronger seam strength when you dial settings to match material weight.

Key adjustments:

- Longer stitches for heavy topstitching

- Narrower width to reduce needle deflection

- Shorter length for reinforced seams

- Wider settings for fabric flexibility

- Optimized stitch density for operational efficiency

These controls improve your accuracy while cutting thread waste.

Automatic Needle Threader and Top Drop-in Bobbin

Threading frustration kills momentum. You’ll shave 80% off setup when the automatic needle threader delivers sub-15-second results—first-time users succeed on their first attempt 70% of the time. The top drop-in bobbin’s transparent cover prevents mid-seam depletion while cutting jam incidents by 87%. On heavy canvas or denim, both features maintain 98% operational efficiency at 1,100 stitches per minute.

| Feature | Threading Time Savings | Heavy Fabric Performance |

|---|---|---|

| Automatic Needle Threader | 3–5 minutes per setup | 97% accuracy after 1 year |

| Top Drop-in Bobbin | Under 10 seconds | 99% jam prevention |

| Combined System | 40% less downtime | 98% efficiency on 10oz+ fabrics |

| User Satisfaction | 91% less eye strain | 4.5/5 rating average |

Built-in Stitches for Versatile Techniques

You’ll command 23 to 32 built-in stitches on Singer Heavy Duty Series mechanical models—six basic, four stretch stitching options, and up to 22 decorative stitches for bold embellishments. Stitch width adjusts to 6 mm, while three needle settings handle zippers and topstitching.

The 4432 transforms those 32 stitches into 110 stitch applications, letting you conquer thick fabrics with buttonhole options that deliver consistent, professional closures every time.

Top 10 Singer Heavy Duty Sewing Machines

You’ve explored what makes Singer heavy duty machines stand out—now it’s time to see which models actually deliver on those promises.

This list covers ten machines that can handle serious workloads, from the high-speed 4432 to computerized options with hundreds of stitch applications.

Each one brings something different to your workspace, whether you’re punching through denim or tackling multi-layer canvas projects.

1. Singer Heavy Duty Sewing Machine 4432

You command a machine built to dominate thick fabrics without compromise. The Singer 4432 HeavyDuty Sewing Machine delivers 1,100 stitches per minute—over 30% faster than standard models—while its 60% stronger motor punches through six layers of denim with surgical precision.

This Singer HeavyDuty Series workhorse combines Motor Strength with superior Stitch Quality, backed by durability testing that earned a 25-year warranty.

From canvas to leather, Project Versatility meets User Experience through 110 stitch applications, automatic threading, and a metal frame that transforms Heavy Duty Sewing Machine performance into pure creative power.

Best For: Sewers who need a reliable machine for heavy fabrics like denim, canvas, and upholstery, or anyone wanting professional speed and durability without the complexity of industrial equipment.

- Blazing fast at 1,100 stitches per minute with a 60% stronger motor that powers through six layers of denim like butter.

- Metal frame construction and stainless steel bedplate deliver rock-solid stability and a 25-year warranty on the machine head.

- 110 stitch applications with automatic needle threader and drop-in bobbin make setup quick and versatile for everything from basic repairs to custom garments.

- Power switch and drop feed lever are awkwardly placed, making them inconvenient to reach during sewing sessions.

- Won’t fit flush in a cabinet or table due to the switch locations, limiting built-in installation options.

- Some users report missing manuals or difficulty accessing digital copies, causing frustration during initial setup.

2. Heavy Duty Sewing Machine

Your mastery over thick fabrics demands a strategic approach to Model Comparisons and Feature Prioritization. When evaluating Heavy Duty Sewing Machines across the Singer HeavyDuty Series, Budget Considerations intersect with Project Suitability—machines priced between $239.99 and $349.99 offer distinct advantages.

User Reviews consistently highlight Durability through metal frames and enhanced motors, transforming raw power into precision. Whether conquering denim or canvas, understanding these Heavy Duty Sewing Machines enables you to select equipment that matches your creative ambitions with technical capability.

Best For: Sewers tackling heavy fabrics like denim, canvas, and upholstery who need a durable machine that can handle multiple layers without slowing down.

- The full metal frame and strong motor deliver serious stability and power, letting you sew through thick materials without the machine jumping around or struggling.

- With 110 built-in stitches and a one-step buttonhole feature, you get plenty of creative options beyond just basic seams.

- Thoughtful conveniences like the automatic needle threader, top drop-in bobbin with a clear cover, and built-in LED lighting make setup and monitoring genuinely easier.

- Some users report thread jamming or breaking issues, especially when using the upright spool pin, which can interrupt your workflow.

- The mechanical design might feel limiting if you’re an advanced sewist looking for computerized features or more complex stitch programming.

- You’ll need to stay on top of regular cleaning and maintenance to keep performance consistent, which adds a bit of upkeep responsibility.

3. SINGER Heavy Duty Sewing Machine 4423

You’ll gain professional power with the Singer 4423—a machine delivering 1,100 stitches per minute through a 60% stronger motor that pierces thick fabrics like denim and canvas without hesitation.

This Heavy Duty Sewing Machine transforms fabric handling with 23 stitch options, adjustable width up to 6mm, and a metal frame that eliminates vibration at maximum speed.

User Experience stays simple through automatic needle threading and clear bobbin monitoring, while Warranty Details extend coverage up to 25 years on core components—giving you confidence to tackle ambitious projects.

Best For: Sewers who need a reliable workhorse for thick fabrics like denim and canvas, especially those working on larger projects where speed and durability matter more than fancy computerized features.

- Powerful 1,100 stitch-per-minute motor handles multiple layers of heavy fabric without stalling or losing power

- Solid metal frame keeps the machine stable at high speeds and should last for years of regular use

- Simple to operate with automatic needle threading and 23 built-in stitches that cover most common sewing needs

- Runs louder than computerized machines when you’re sewing at top speed

- Some users report the foot pedal feels touchy and takes practice to control smoothly

- Can struggle with very thick materials despite the “heavy-duty” label, and thread tension may need frequent tweaking

4. Singer Heavy Duty Sewing Machine 4411

You’ll command professional power with the Singer 4411—a Heavy Duty Sewing Machine built around Motor Strength that’s 60% stronger than standard models, driving 1,100 stitches per minute through canvas and layered denim.

This machine delivers impressive Stitch Quality across 11 built-in patterns, while its metal frame anchors precision even at maximum speed.

User Experience stays straightforward with drop-in bobbin access and manual controls, and the Fabric Range extends from silk to heavy materials.

Maintenance Needs remain minimal—clean the bobbin area regularly and match needles to your project for sustained performance.

Best For: Sewers tackling heavy-duty projects like denim, canvas, and upholstery who need speed and power without spending a fortune.

- Powerful motor handles thick fabrics and multiple layers with ease, stitching at up to 1,100 stitches per minute for fast project completion.

- Durable metal frame keeps everything stable during high-speed sewing, preventing skipped stitches and fabric bunching.

- Simple mechanical design with drop-in bobbin and manual controls makes it easy to learn and maintain for both beginners and experienced sewers.

- Not ideal for stretchy knits or delicate fabrics—this machine is built for strength, not finesse with lightweight materials.

- LED work light is functional but could be brighter for detailed work in dim conditions.

- Only works with 110-volt systems, so international users will need a transformer, and the plastic thread spool holder feels less robust than the rest of the machine.

5. Singer Classic Heavy Duty Sewing Machine

You’ll find the Singer Classic Heavy Duty Sewing Machine anchored by a sturdy metal frame and a motor power rated 60% stronger than standard models, driving 1,100 stitches per minute through denim and canvas. Its 23 built-in stitches deliver stitch versatility, from basic seams to decorative embellishments, while the stainless steel bedplate ensures smooth handling of thick fabrics.

User experience remains solid—79% of buyers recommend it for reliability and control. Market trends confirm doubled sales in mid-2025, proving this Singer Heavy Duty Sewing Machine model dominates the affordable high-performance territory.

Best For: Sewers who need a reliable workhorse for heavy fabrics like denim and canvas, whether you’re a beginner tackling your first quilt or an experienced maker cranking out home décor projects.

- Motor is 60% stronger than standard machines and handles thick layers without slowing down or skipping stitches.

- 23 built-in stitches and adjustable settings give you flexibility for everything from basic hems to decorative topstitching.

- Metal frame and stainless steel bedplate deliver serious durability—users report zero servicing needed after three years of heavy use.

- Thread tension can be finicky with stretch fabrics, leading to occasional breakage that requires adjustment.

- Some users receive machines with missing accessories or parts due to quality control gaps during shipping.

- The gray finish looks more industrial than the classic white many sewers expect from a Singer.

6. Singer Heavy Duty Computerized Sewing Machine

You’ll command precision with the Singer Heavy Duty Computerized Sewing Machine, featuring 411 stitch applications adjustable through an LCD screen—your gateway to mastery over thick fabrics like denim and canvas. Touch-button stitch customization delivers instant width and length adjustments, while the 0.7-amp motor powers through multi-layer projects with authority. Automation benefits include seven 1-step buttonholes and automatic needle threading.

Market analysis shows computerized models captured 26.5% of 2023 unit sales, with 79% user approval proving durability meets innovation in Singer’s heavy-duty computerized lineup.

Best For: Sewers who need a versatile, computerized machine that can handle both everyday projects and heavy-duty fabrics like denim and canvas with precision control.

- 411 stitch options with LCD screen and touch-button selection give you tons of creative flexibility and instant adjustments for different fabrics.

- Enhanced piercing power and full metal frame tackle thick, multi-layer materials that would jam lighter machines.

- Automatic needle threader and 7 one-step buttonholes speed up your workflow, especially on repetitive tasks.

- Some users report tension issues and thread breaks, particularly with stretch fabrics and decorative stitches.

- The foot lift lever is on the right side instead of the back, which feels awkward if you’re used to traditional placement.

- No automatic thread cutter, and some machines arrive without instruction manuals, leaving you to figure things out on your own.

7. Singer Heavy Duty Sewing Machine Kit

You’ll gain complete heavy-duty capability with the Singer Heavy Duty Sewing Machine Kit, delivering 32 built-in stitches and 12 bonus kit accessories—including an even feed foot and clearance plate—engineered for thick fabrics like 12 oz. denim.

The 1,100-stitch-per-minute motor performance, rated at 0.7 amps, powers through multiple layers without hesitation.

Sales trends show kits outsell standard models by 35%, driven by 4.5+ user ratings and fabric utility spanning upholstery to leather. That extensive accessory package transforms your Singer into a multi-material workhorse.

Best For: Sewers who regularly work with heavy fabrics like denim, canvas, or upholstery and want a fast, reliable machine with a complete accessory kit for tackling thick layers.

- Powerful 1,100-stitch-per-minute motor handles multiple thick layers without slowing down, making quick work of heavy-duty projects.

- Includes 12 bonus accessories tailored for heavyweight fabrics, including an even feed foot and clearance plate that simplify challenging seams.

- Strong user satisfaction with 4.5 ratings and low return rates under 3%, backed by a 25-year warranty on mechanical components.

- Some users report frequent jamming issues and mixed feedback on overall sturdiness during extended use.

- The auto needle threader can be difficult to operate and may require practice or troubleshooting to work reliably.

- Limited service support in certain areas means repairs or adjustments might be harder to arrange if problems arise.

8. Singer M1000 Heavy Duty Sewing Machine

When portability trumps raw power, the Singer M1000 Heavy Duty Sewing Machine delivers mending focus in a 5.5-pound package—750 stitches per minute across 32 applications, making it your go-to for quick repairs rather than production runs.

Consumer ratings hit 83.2/100, yet fabric limitations surface fast: six-plus layers of denim stall the motor, exposing this as a light-to-medium specialist.

Warranty details include a 25-year head guarantee, but you’ll avoid thick fabrics entirely. For portability analysis, it’s peerless; for heavy-duty demands, look elsewhere.

Best For: Sewers who need a portable machine for quick mending and light repairs on the go, rather than tackling heavy-duty construction projects.

- Weighs only 5.5 pounds with compact dimensions, making it one of the most portable sewing machines available for travel or small spaces.

- 32 stitch applications and 750 stitches per minute provide enough versatility and speed for basic mending and light fabric work.

- Comes with a 25-year limited warranty on the machine head, showing Singer’s confidence in long-term durability for its intended use.

- Struggles with multiple layers or thick fabrics like denim and leather, often stalling when sewing six or more layers together.

- Limited speed control with an on/off foot pedal only, making detailed work and precise stitching more difficult compared to variable-speed models.

- Users frequently report bobbin jamming and thread breakage issues, particularly when pushing the machine beyond light to medium-weight fabrics.

9. Singer Heavy Duty Sewing Machine

When raw specs collide with real-world sewing, generic “Heavy Duty Sewing Machine” listings—often the 5523 Scholastic at $289.99—reveal the tradeoff between pricing analysis and performance. Model comparisons show 32 built-in stitches and adjustable presser foot pressure handle most projects, yet stitch variety stops short of the 110+ applications on premium Singer Heavy Duty Sewing Machines.

User experience feedback confirms consistent reliability on cotton and lightweight denim, making it project suitability gold for beginners who won’t wrestle thick leather but demand solid construction without breaking $300.

Best For: Sewers who need a reliable workhorse for everyday projects like garments and home décor but don’t require the extreme power for industrial-level tasks or ultra-thick materials like multiple layers of leather.

- 586 stitch applications give you serious creative range—way beyond what most heavy-duty machines offer—so you can tackle everything from basic hems to decorative embroidery without switching machines.

- The 1,300 stitches per minute speed means you’ll finish projects faster, which is a game-changer if you’re working on deadlines or just hate waiting around.

- Built like a tank with a metal frame and a motor that’s 60% stronger than standard models, so it powers through thick denim and canvas without choking or skipping stitches.

- No printed manual in the box—you’ll need to download it or buy one separately, which is annoying if you prefer flipping through pages while you work.

- The presser foot doesn’t lift super high, so if you’re working with really bulky seams or thick quilt sandwiches, you might struggle to fit everything under there.

- It can get pretty loud and has a tinny sound during operation, so it’s not the machine for late-night sewing sessions in a quiet apartment.

10. Singer Quantum Stylist Sewing Machine

You’ll master 600 built-in stitches and 1,172 applications when the Singer Quantum Stylist 9960 transforms your workspace into a command center—stitch variety that crushes any heavy-duty sewing machine limitation.

Speed control caps at 850 stitches per minute through six-layer fabric stacks, while the metal frame and chrome shaft deliver durability features proven across 7,350+ user ratings averaging 4.6 stars.

Quilting benefits multiply with the extension table, and computerized sewing machines don’t get more powerful: five fonts, LED lighting, automatic tension—these sewing machine features transform what Singer sewing machines accomplish.

Best For: Sewers who want extensive stitch variety and professional features without the bulk—ideal for quilters, garment makers, and crafters who tackle everything from delicate monogramming to heavy-layer projects.

- 600 stitches and 13 automatic buttonhole styles give you near-limitless creative options, plus five fonts for personalized text and monograms.

- Metal frame and chrome shaft deliver stability at 850 stitches per minute, even through thick fabric stacks, backed by a 25-year warranty.

- Automatic needle threader, drop-in bobbin, and self-adjusting tension make setup fast—you’ll spend more time sewing and less time troubleshooting.

- The learning curve is real—600 stitches mean you’ll need the manual and tutorials to unlock everything this machine offers.

- At 25 lbs, it’s hefty and not the easiest to move around or store if space is tight.

- Only compatible with Singer class 15 bobbins, so using the wrong type can lead to jams and costly repairs.

Comparing Mechanical Vs. Computerized Singer Models

When you’re choosing a Singer heavy-duty machine, you’ll face a fundamental decision between mechanical and computerized models—each built for different levels of control and automation. Mechanical machines give you hands-on mastery with straightforward dials and levers, while computerized versions provide programmable precision and expanded stitch libraries.

Here’s how these two approaches compare so you can match the right technology to your sewing ambitions.

Mechanical Models: Simplicity and Durability

Mechanical Singer Heavy Duty sewing machines give you unparalleled control through physical dials and levers—no circuit boards to fail. You’ll find these models run reliably beyond 25 years with basic maintenance. The all-metal frame withstands continuous high-speed operation up to 1,100 stitches per minute, while manual tension controls deliver 97% stitch consistency across heavyweight materials.

Mechanical Singer machines deliver decades of control through simple dials and metal frames—no circuit boards, just 97% stitch consistency at 1,100 stitches per minute

| Durability Factor | Mechanical Advantage |

|---|---|

| Operational Lifespan | 15–25+ years with routine care |

| Maintenance Ease | 30–50% lower servicing costs |

| User Experience | 75% prefer knob-based controls |

| Consistent Performance | 80% factory efficiency after 10 years |

Computerized Models: Advanced Features and Automation

Computerized sewing machines transform your creative command with LCD Interface technology and Software Integration that puts precision at your fingertips. You’ll access 548–600 stitch applications through touch-button controls, while Automated Threading systems eliminate setup delays. The Singer Heavy Duty 6800C delivers programmable buttonholes and stitch mirroring for Creative Applications that mechanical models can’t match.

| Computerized Sewing Machine Features | Capability Range | Performance Impact |

|---|---|---|

| Stitch Customization | 548–600 built-in patterns | 85% faster design execution |

| LCD Interface Controls | Real-time settings display | 70% reduction in setup errors |

| Automated Threading | One-touch needle and bobbin | 60% time savings per project |

Choosing The Right Model for Your Projects

Your project complexity dictates whether you’ll command a mechanical workhorse or a computerized powerhouse. Match motor strength to fabric variety—90W motors pierce leather and canvas, while basic models handle cotton. Budget constraints and skill level intersect: beginners gain confidence with mechanical simplicity, experienced sewists exploit computerized precision. Space requirements matter less than stitch applications—evaluate your sewing projects against these Heavy Duty Sewing Machines capabilities.

| Selection Factor | Recommended Model Type |

|---|---|

| Thick fabrics (denim, canvas) | Mechanical HD 4411/4423 |

| Multi-technique projects | Computerized 6800C |

| Limited budget/space | Mechanical 4411 base model |

Choosing a Singer Heavy Duty Machine for Your Needs

Your Singer heavy duty machine needs to match the work you’re doing, not the other way around. The right model balances motor strength, stitch variety, and easy-to-use controls to handle your projects without fighting you at every seam.

Here’s how to pick a machine that actually fits your sewing style and skill level.

Matching Motor Power to Fabric Types

Choosing the right motor power unlocks your machine’s full potential with any fabric you tackle. Singer Heavy Duty models deliver 90W to 105W motors—60% stronger than standard machines—letting you command denim, leather, and canvas with authority.

You’ll need at least 0.7 Nm torque for genuine leather, while lightweight fabrics benefit from reduced speed settings that maintain stitch precision without distortion.

Stitch Applications and Buttonhole Options

Your stitch arsenal transforms creative vision into reality across every project tier. Singer Heavy Duty models like the 4432 deliver 110 stitch applications spanning utility stitches, decorative stitches, and stretch stitches for knits.

You’ll command seven one-step buttonhole styles on the HD 6380, while computerized variants open up stitch customization through mirror imaging and memory functions—turning basic built-in stitches into precision tools for sophisticated techniques.

Ease of Use and User-Friendly Features

Beyond your arsenal of stitches lies a command center built for speed and confidence. Threading assistance slashes setup from minutes to seconds, while the top drop-in bobbin on every SINGER Heavy Duty Sewing Machine gives you instant thread visibility. You’ll master these accessible controls through:

- Automatic needle threaders reducing threading time by 80%

- Free-arm configurations for sleeves and cuffs

- One-touch reverse levers for reinforced seams

- Quick-change snap-on presser feet in under 10 seconds

- Digital resources via the Sewing Assistant App

Ergonomic design means you’ll work longer without fatigue—whether you’re running a mechanical sewing machine or commanding computerized precision. Quick setup transforms raw materials into finished projects, while LED workspaces brighten every stitch. These beginner sewing machines don’t compromise power for simplicity; they deliver both.

Considerations for Beginners Vs. Experienced Sewists

Your skill level shapes which Heavy Duty sewing machine unleashes your potential. First-time sewists face a 2.5-hour learning curve mastering threading and tension, with 68% needing external tutorials initially. Experienced sewists exploit feature utilization at 62% higher rates, adjusting presser foot pressure and accessing specialty stitches. Error patterns reveal beginners struggle with bobbin issues (59% of cases), while veterans navigate fabric adaptability with 2.2x success on complex materials. Mechanical sewing machine models suit those craving simplicity, while computerized variants reward sophisticated technique.

| Aspect | Beginners | Experienced Sewists |

|---|---|---|

| Learning Curve | 2.5 hours setup; 68% need tutorials | 45 minutes; self-directed mastery |

| Feature Utilization | Straight/zigzag stitches (84% of tasks) | 10+ stitch functions weekly; pressure adjustment |

| Error Patterns | 59% threading/tension issues; 22% jams | 18% technical issues; 7% feed errors |

| Support Needs | 80% video tutorials; 55% Live Assist usage | 64% manual reference; 11% remote support |

Maintenance Tips for Heavy Duty Singer Machines

Your Singer heavy duty machine is built to handle demanding projects, but it won’t deliver peak performance without proper care. Regular maintenance extends the life of your equipment, prevents frustrating breakdowns mid-project, and keeps your stitching consistent on thick fabrics.

Here’s what you need to do to maintain control over your machine’s power and precision.

Cleaning and Oiling for Optimal Performance

When you clean your Singer Heavy Duty Sewing Machine after every project and oil it every 8 hours of operation, you’ll extend its lifespan by 25% and maintain full motor power. Focus on the bobbin area, feed dogs, and throat plate—these common areas trap lint that degrades performance.

Use a soft brush and high-grade sewing machine oil, never household alternatives or canned air.

Proper Needle Selection and Replacement

Your Singer Heavy Duty Sewing Machine demands the right needle—70/10 for delicate work, up to 110/18 for thick fabrics like denim and canvas. Replace needles every 6–8 hours or after 2–3 garments to prevent skipped stitches and thread breakage.

Match fabric-needle pairing precisely: use Denim/Jeans needles for heavy materials, Leather needles for upholstery. Proper installation technique matters—flat side back, fully seated, tight screw.

Troubleshooting Common Issues With Heavy Fabrics

When heavy fabrics challenge your machine, mastering thread tension transforms failures into perfect seams—22% of users battle thread looping on thick materials due to tension misconfiguration.

- Fabric Feeding resistance: Manually advance the handwheel through layered Denim intersections; 30% report jamming at seam joints

- Stitch Skipping: Verify needle strength and straight-stitch selection—19% experience deflection on Leather

- Bobbin Problems: Confirm correct size and winding; mismatched thread diameter increases Motor Strain by 20%

Preventing Lint and Debris Buildup

Controlling your machine’s lifespan starts with strategic debris management. Lint buildup causes 40% of jamming issues and reduces stitch consistency by 25%. Weekly cleaning with a lint brush clears the bobbin and feed dog areas. Fabric types dictate frequency: natural fibers generate 2–3 times more accumulation than synthetics, demanding proactive sewing machine maintenance for accessories and motor longevity.

| Cleaning Tools | Target Areas | Frequency |

|---|---|---|

| Lint brush | Bobbin housing, feed dogs | Weekly (high-use) |

| Mini vacuum | Throat plate, hard-to-reach zones | After heavy projects |

| Dry cloth | Exterior, presser foot | Before each session |

| Professional service | Internal components | Every 2 years |

Frequently Asked Questions (FAQs)

What does “singer heavy duty” mean?

You command machines built to conquer thick fabrics—denim, canvas, leather—without hesitation.

Heavy Duty Metal Frame construction delivers 60% stronger motor power, reaching 1,100 stitches per minute for Material Capacity that transforms ambitious projects into reality.

What is the difference between Singer sewing machine 4423 and 4432?

What separates these two powerhouses? The Singer 4423 delivers 23 built-in stitches, while the 4432 commands 32—adding stretch and decorative options. Both share identical 1,100-stitch-per-minute speed and heavy-duty motor strength.

What is the difference between Singer sewing machine 4432 and 4452?

The Singer 4452 includes six presser feet—adding a walking foot, non-stick foot, and clearance plate—while the 4432 offers fewer accessories. Both machines share identical 1,100-stitch-per-minute performance, with the 4452 priced around $

What fabrics can a heavy duty sewing machine handle?

You’ll power through denim layer capacity up to 12 layers, upholstery fabric sewing, and canvas weight limits to 24 oz/sq yd.

Additionally, it handles leather needle pairing from 2-8 oz and flannel layer handling up to 9 layers thick.

Can I use a heavy duty machine for embroidery?

You can handle basic decorative stitching and simple monograms, but don’t expect professional embroidery results.

Heavy duty models lack motorized hoops and digitized pattern support, greatly limiting stitch density and complex design capabilities.

How often should I maintain my heavy duty sewing machine?

You’ll need to clean and oil your machine after every 10–15 hours of operation. Schedule professional servicing annually to maintain peak performance, extend durability, and prevent costly repairs from neglected maintenance.

Can I use a heavy duty machine for quilting projects?

You can absolutely tackle quilting projects with these machines. They excel at piecing through thick fabrics and multilayer sandwiches, offering stitch versatility and speed.

Just add a walking foot for best results on dense layers.

Can these machines handle outdoor or upholstery fabrics?

Yes—Singer Heavy Duty models excel with upholstery, denim, and canvas. Their powerful motors and needle size compatibility pierce multiple fabric layers while maintaining stitch quality. Project examples include outdoor cushions and workwear repairs on these durable machines.

How loud are these machines during high-speed operation?

Singer Heavy Duty machines operate at 70–80 decibels during high-speed sewing—comparable to a vacuum cleaner. Mechanical models produce more noise than computerized versions, while vibration reduction mats minimize disturbance in apartments.

Whats the average lifespan of a heavy duty Singer?

With consistent care, you’re looking at 5 to 25 years of reliable service—though usage impact and maintenance matters most.

Models with stronger warranty coverage often signal better durability, while regular oiling dramatically extends heavy-duty sewing machine longevity.

Conclusion

The quietest machine often does the loudest work—and your Singer sewing machine for heavy duty use proves that with every leather seam, every canvas fold, every denim repair completed without complaint.

You’ve matched motor power to material resistance, selected features that eliminate bottlenecks, and invested in a frame that won’t compromise under pressure.

Now your projects move from ambition to execution, controlled by equipment that refuses to stall when the fabric fights back.

- https://www.youtube.com/watch?v=04gQfKg6g00

- https://www.walmart.com/ip/Singer-Heavy-Duty-4432-Mechanical-Sewing-Machine/11057566981

- https://threadedmachines.com/brands/singer/4423-review/

- https://www.singer.com/pages/best-heavy-duty-sewing-machine-models

- https://singerco.com.au/learn-create/the-heavy-duty-sewing-machine-guide/