This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Heavy fabric demands machines engineered specifically for high-tensile loads: reinforced needle bars, servo motors that maintain torque under resistance, and differential feeds calibrated to prevent fabric stretch at the cutting blade.

This review examines ten overlock machines built to manage weights from 12-ounce canvas to layered upholstery without the mechanical failures that plague standard sergers. You’ll find the specifications that separate equipment capable of sustained heavy-fabric production from machines that simply claim the capability.

Table Of Contents

- Key Takeaways

- Best Overlock Machines for Heavy Fabric

- 1. Professional Serger Overlock Sewing Machine

- 2. Singer Metal Frame Serger Machine

- 3. Feiyue Serger Overlock Sewing Machine

- 4. Industrial Grade Serger Sewing Machine

- 5. Heavy Duty Industrial Overlock Machine

- 6. Lumina Serger Overlock Sewing Machine

- 7. Brother Strong and Tough Serger

- 8. Singer Metal Frame Overlock Serger

- 9. Metal Frame Serger Sewing Machine

- 10. Heavy Duty Serger Sewing Machine

- Key Features of Heavy-Duty Overlockers

- Overlock Vs Regular Sewing Machines

- Choosing The Right Overlocker for Thick Fabric

- Performance and Efficiency in Industrial Use

- Common Mechanical Challenges

- Maintenance and Downtime Reduction

- Automation and Smart Features

- Price Range of Heavy-Duty Models

- Financing and Leasing Options

- Long-Term Savings With Servo Motors

- Energy Consumption in Manufacturing

- Needle and Thread Selection

- Adjusting Tension and Feed Settings

- Preventing Common Stitch Problems

- Maintaining Seam Quality and Durability

- Clean Edge Finishing Methods

- Reinforced Seams for Durability

- Decorative Overlock Stitches

- Handling Bulk and Layered Fabrics

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Heavy-duty overlock machines require reinforced needle bars, servo motors that maintain torque under load, and differential feeds calibrated for 12-ounce canvas or thicker materials to prevent the mechanical failures and needle breaks that cost you fifteen minutes of downtime per incident during production runs.

- Industrial models operating at 7,000 to 9,500 stitches per minute with 400–750W motors deliver throughput gains up to 47% in factories, while servo technology cuts energy consumption by 60–80% and reduces unscheduled downtime by 15–20% compared to clutch-driven systems.

- Proper setup for thick fabrics demands size 16/100 to 18/110 needles, Tex 40–70 thread weights, differential feed ratios between 1.5 and 2.0, and reduced presser foot pressure to prevent skipped stitches, puckering, and seam failure on multilayer denim or upholstery materials.

- Metal frame construction reduces vibration by 30% and extends machine lifespan beyond 10 years with consistent maintenance protocols—including oiling every 7–8 hours and professional servicing annually—that cut production downtime and maintain stitch quality across continuous heavy-fabric operations.

Best Overlock Machines for Heavy Fabric

When you’re ready to tackle heavy fabrics like denim, canvas, or upholstery material, you need an overlock machine built for the challenge. The right model won’t just manage thick layers—it’ll give you clean edges, strong seams, and the control to finish projects with confidence.

Below, you’ll find ten heavy-duty overlock machines that handle what standard sergers can’t.

1. Professional Serger Overlock Sewing Machine

You’ll find the Professional Serger Overlock Sewing Machine manages heavy fabric with 1,200 stitches per minute and a sturdy 4-thread design that delivers stronger, more compact seams. Its edge locking and trimming capabilities simplify fabric management, while the 100W motor maintains consistent power.

This model features an adjustable stitch pitch from 0.1 to 0.13 inches, letting you fine-tune machine settings for peak sewing efficiency across leather, denim, and layered materials.

Keep your serger in good shape and get comfortable with overlocking, and you’ll turn out seams that hold their own against the industrial machines featured in top reviews.

Best For: Sewers who need a reliable 4-thread overlocker for handling diverse fabrics—from delicate materials to heavy-duty leather—at speeds up to 1,200 stitches per minute.

- Adjustable stitch pitch (0.1-0.13 inches) gives you precise control over seam tension and finish quality across different fabric types

- Built-in LED light and foot-switch operation make extended sewing sessions more comfortable, especially in dimly lit workspaces

- Dual edge locking and trimming function streamlines your workflow by finishing seams and cutting excess fabric in one pass

- Threading can be tricky without clear instructions, and some users report missing hardware like screws upon delivery

- No thread included with the machine, so you’ll need to budget for compatible spools separately

- Higher noise levels during operation are typical for machines with robust 100W motors, which may be disruptive in quiet environments

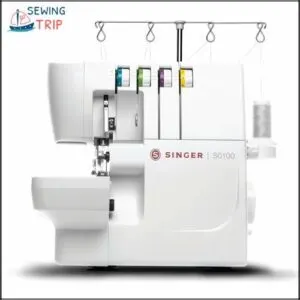

2. Singer Metal Frame Serger Machine

The Singer Metal Frame Serger Machine steps up from the previous model with a 60% larger cutting knife and a reinforced metal frame that won’t shift when you’re pushing through denim or upholstery. You’re getting 1,300 stitches per minute and a color-coded threading system that cuts setup time.

This heavy duty SINGER serger manages 2, 3, or 4-thread configurations across six stitch types, and the extra-high presser foot clears thick seams without hesitation.

Sewing machine reviews consistently rate it 4.3 stars for industrial reliability and skip-free sewing performance, making it a standout in any overlock machine comparison for serious fabricators.

Best For: Sewers tackling heavy fabrics like denim and upholstery who need professional-grade seam finishing at high speed without constant mechanical issues.

- Metal frame and 60% larger knife handle thick materials without skipping stitches, delivering consistent results even on eight-layer denim seams at 1,300 stitches per minute.

- Adjustable differential feed and extra-high presser foot prevent puckering and accommodate bulky layers, making transitions between fabric weights seamless.

- Color-coded threading system and six stitch configurations (2/3/4-thread) offer versatility for rolled hems, flatlock seams, and decorative edges without swapping plates.

- Manual threading remains frustrating for some users despite color coding, with reports of a learning curve that slows initial setup.

- The small scrap bag requires DIY modifications or frequent emptying during extended sessions, interrupting workflow.

- Regular oiling and maintenance are mandatory to sustain performance, and some users report difficulty interpreting the instruction manual for optimal settings.

3. Feiyue Serger Overlock Sewing Machine

Feiyue Serger Overlock Sewing Machine delivers 1,300 stitches per minute with a color-coded threading system that locks you into rapid production cycles on heavy material. The reinforced metal chassis holds steady through denim and multilayer construction, while the high-durability carbon steel blade gives you outstanding cutting precision.

You’ll configure 2, 3, or 4-thread setups to match your Overlock Performance demands, and the adjustable differential feed prevents puckering when you’re pushing through thick textiles.

At $159.99, it’s positioned for home-based and small garment operations that need Sewing Efficiency without breaking the budget, though some users report foot-pedal responsiveness issues that require attention during Serger Maintenance.

Best For: Home sewers and small garment businesses who need industrial-grade serging speed and multi-thread versatility for heavy fabrics without spending on high-end brands.

- Handles thick materials like denim and multilayer fabrics at 1,100-1,200 stitches per minute with a reinforced metal frame that stays stable during high-speed operation

- Color-coded threading system with numbered loopers makes setup faster and reduces mistakes when switching between 2, 3, or 4-thread configurations

- Priced competitively at $159.99-$400 depending on model, offering adjustable differential feed and rolled hem features that usually come with pricier machines

- Foot pedal can be inconsistent with unintentional acceleration or lag, creating control issues and potential safety concerns during precision work

- Performance may drop on ultra-heavy upholstery-grade materials, and some users report threading difficulties with the lower looper plus occasional needle breakage

- Limited availability of replacement parts and qualified repair technicians outside primary distribution areas can make long-term maintenance challenging

4. Industrial Grade Serger Sewing Machine

Industrial Grade Serger Sewing Machine operates at 7,000 to 9,500 stitches per minute, giving you the power to process heavy fabric at speeds that reshape garment manufacturing throughput. You’ll command 400 to 750 watts of motor force, engineered for continuous operation on dense textiles and multilayer constructions without thermal compromise.

AI-driven fabric management systems cut management errors by 33%, while programmable controls let you store up to 25 stitch patterns for denim, canvas, and upholstery applications.

The Asia-Pacific region accounts for over 50% of industrial serger adoption, and factories upgrading to these machines report throughput gains of up to 47%—proof that sewing automation transforms textile industry output and machine durability when you’re working at scale.

Best For: Large-scale textile manufacturers, automotive upholstery shops, and heavy-duty garment factories needing high-speed processing of dense fabrics like denim, canvas, and multilayer materials.

- Operates at 7,000 to 9,500 stitches per minute with 400-750W motors, delivering industrial throughput that can boost factory output by up to 47% compared to standard machines.

- AI-driven fabric management cuts handling errors by 33%, while programmable controls store up to 25 stitch patterns for consistent quality across heavy materials up to 12mm thick.

- Advanced servo motors reduce energy consumption by 65% compared to clutch systems, lowering annual electricity costs to around $108 per machine while maintaining continuous operation capability.

- High upfront investment compared to domestic sergers, with industrial models typically priced significantly above consumer-grade alternatives like the $215.99 Lumina Sienna.

- Requires strict maintenance schedules with oiling every 7-8 hours and needle replacement every 40 operational hours—neglecting maintenance increases thread breakage by 25%.

- Operates at noise levels higher than home machines and demands skilled operators to manage speeds safely, plus replacement parts can be difficult to source depending on manufacturer support networks.

5. Heavy Duty Industrial Overlock Machine

For real muscle in garment manufacturing, a heavy duty industrial overlock machine is your workhorse when wrestling with heavy fabric. These overlock machines feature powerful motors, programmable automation, and knife systems designed for dense textiles.

These machines handle up to 1,500 stitches per minute with 4- or 5-thread operations, making fabric handling smoother while cutting down on downtime.

If you’re looking for mastery in industrial sewing, attentive machine maintenance and daily calibration are essential—these units empower you to tackle bulk orders with unwavering seam quality.

Best For: High-volume factories, commercial sewing businesses, or anyone needing fast, precise seams on tough fabrics.

- Delivers consistent, professional results at extremely high speeds for rapid production.

- Handles thick materials and complex textiles with ease, thanks to strong motors and advanced feed systems.

- Built-in smart features and automation reduce operator fatigue and boost efficiency.

- Requires a bigger upfront investment and may be overkill for home or small shop use.

- These machines are large and need dedicated space plus regular, skilled maintenance.

- Can consume significantly more power than standard home models, raising energy costs.

6. Lumina Serger Overlock Sewing Machine

If you demand a serger that pulls its weight, the Lumina Serger Overlock Sewing Machine stands out. It packs sturdy Lumina Features—high-speed stitching up to 1,250 per minute, a metal frame, and color-coded threading for efficient Thread Management.

Overlock Accessories help simplify Serger Maintenance and boost Sewing Efficiency, even on heavy fabrics. Adjust the differential feed to avoid puckering and tackle multiple layers.

For clean Overlock Stitch results, this machine rewards mastery of proper tension and essential Sewing Techniques.

Best For: Busy home sewists and small workshop creators who need a durable, fast, and portable serger for a wide range of projects.

- High-speed stitching and strong motor for smooth results on thick or layered fabrics.

- Easy threading with a color-coded guide and wide access points for quick setup.

- Portable, durable build with free arm and adjustable controls for versatile use.

- Initial threading and tension adjustments can be tricky for newcomers.

- Instruction manual may not cover every technique or tricky setting.

- Not ideal for heavy-duty industrial or oversized projects.

7. Brother Strong and Tough Serger

Every seasoned operator knows the Brother Strong and Tough Serger isn’t just another serger machine—it sets a high bar for anyone facing heavy fabric sewing day in, day out. Its metal frame and carbon steel blade boost longevity, while color-coded threading and underlooper threader make routine serger maintenance far less intimidating.

With 1,300 stitches per minute and fine-tuned thread tensioning, this overlock machine delivers consistent overlock stitch quality. Excellent fabric compatibility allows precise garment construction, no matter the thickness you’re tackling.

Best For: Anyone who regularly sews thick fabrics and wants a reliable, high-speed serger for heavy-duty projects.

- Metal frame and extra-hard carbon steel blade provide real stability and years of smooth use.

- Runs up to 1,300 stitches per minute, making big projects fast and efficient.

- Easy, color-coded threading and included accessory feet keep it user-friendly for various sewing tasks.

- Threading can be tricky for beginners, so there may be a learning curve.

- Not recommended for very thin or delicate fabrics—works best with heavier materials.

- Limited to US voltage (120V), so you can’t use it everywhere.

8. Singer Metal Frame Overlock Serger

Built for your toughest jobs, the Singer Metal Frame Overlock Serger redefines what edge finishing means in the realm of heavy fabric.

This SINGER Serger Machine doesn’t flinch at layered denim or coated canvas—its extra-large cutting knife and stainless steel bedplate keep material moving smoothly, even when pressure’s on.

With 1,300 stitches per minute and a free-arm for circular seams, you hold the power to master both strength and sewing efficiency. Expect consistent results on every heavy-duty project you tackle.

Best For: Anyone who needs a reliable, heavy-duty serger to create strong, professional seams and finishes on thick or layered fabrics like denim, canvas, or fleece.

- Handles layered heavy fabrics with ease thanks to a high-powered cutting knife and robust metal frame.

- Fast sewing speed (1,300 stitches/min) and a free arm boost productivity on large or circular projects.

- Color-coded threading paths and bright LED lights simplify setup and improve visibility.

- Threading and setup can still be tricky despite color guides, especially for beginners.

- Some users report issues with the foot pedal and the machine not arriving pre-threaded.

- Finding replacement parts or getting technical help may take extra time and effort.

9. Metal Frame Serger Sewing Machine

Think of a serger with a backbone—Metal Frame Construction in a serger sewing machine isn’t just about brute strength, it’s your insurance for smooth performance. After countless Machine Durability Tests, these Overlock Machines consistently outlast lightweight rivals, holding tension and speed under load.

Reinforced frames make heavy fabric work far less daunting—they cut through canvas and linen with equal ease.

For industrial-grade reliability that stands up to serious use, invest in solid construction and stay on top of routine maintenance.

Best For: Sewers who regularly work with heavy fabrics like denim, canvas, or upholstery and need a durable machine that can handle high-speed production without losing precision.

- Metal frame construction reduces vibration by up to 30% and provides exceptional stability when sewing thick, layered materials at speeds up to 1,300 stitches per minute.

- Differential feed system prevents stretching and puckering on heavy fabrics, while the extra-high presser foot lift accommodates layers up to 5mm thick.

- Built to last over 10 years with proper maintenance, featuring durable components like carbon steel blades and a reinforced frame that outlasts lightweight alternatives.

- Requires regular maintenance every 8-10 hours of sewing, with professional servicing recommended annually to maintain peak performance.

- Replacement parts can have longer wait times due to the machine’s complex construction compared to standard sergers.

- New machines may have a strong oil smell initially, and threading requires practice and patience, especially for beginners unfamiliar with serger operation.

10. Heavy Duty Serger Sewing Machine

When you’re pushing up to 1,300 stitches per minute through denim or upholstery, you need a workhorse—Heavy Duty Serger Sewing Machines deliver that power with full metal frames and motors rated between 95 and 122 watts. These Overlock Machines manage thick linens and canvas without skipping, thanks to differential feed and extra-high presser foot lift.

Follow solid Serger Maintenance protocols and you’ll cut downtime by 30 percent, a critical edge in any Industrial Sewing Safety program.

In any Sewing Machine Comparison, servo-equipped models prove their worth with 35 percent better energy efficiency—Heavy Fabric Tips don’t get more practical than that.

Best For: Small workshops, home sewers, and budget-conscious crafters who need to finish seams and handle fabrics from chiffon to thick linen without investing in industrial equipment.

- Blazing speed up to 1,300 stitches per minute with 2–4 thread versatility lets you finish garments fast and experiment with rolled hems, flat-locks, and blind hems.

- Full metal frames and stainless steel bedplates deliver stability and smooth fabric glide, even when you’re stacking multiple layers of denim or canvas.

- Servo motors in higher-end models cut energy costs by 35 percent while differential feed prevents puckering on stretchy or heavy textiles.

- Threading can frustrate beginners—color-coded charts help, but some users still find the process confusing and time-consuming.

- LED lights occasionally shine directly into your eyes, and a few customers report broken needles, loose knives, or occasional machine malfunctions.

- Not built for continuous industrial use, so regular oiling and maintenance are necessary to keep performance consistent over time.

Key Features of Heavy-Duty Overlockers

When you’re working with denim, canvas, or upholstery materials, your overlocker needs to deliver more than basic edge finishing.

The right heavy-duty machine combines sturdy construction with specialized features that let you maintain control over thick, demanding fabrics.

The difference comes down to how well your machine handles stress when fabric thickness tests its limits.

Multiple Thread Capability

When you’re running heavy denim or canvas through your overlock at full speed, the difference between a 2-thread and a 4-thread machine can mean the gap between seams that hold up to industrial wear and ones that split at the first sign of stress.

Most heavy-duty overlock machines offer 3-thread or 4-thread configurations, giving you control over stitch variety and fabric compatibility. The looper threads and needle threads work together to create reinforced edges, while micro thread control lets you dial in precise thread tensions for different materials and color options.

Adjustable Cutting Blades

Your blade assembly isn’t just trimming excess—it’s the gatekeeper between ragged cutoffs and precision edges that feed cleanly into your looper system, especially when you’re pushing 12-ounce denim or upholstery canvas through at production speed.

Blade sharpness dictates how cleanly your overlock machine manages fabric trimming without drag or pull. You’ll want adjustable cutting width controls—most heavy-duty serger machines let you dial in blade adjustment from 3mm to 7mm, giving you the cutting precision needed for variable seam allowances and edge finishing that doesn’t compromise your weaving integrity.

Enhanced Motor Power

Raw cutting precision means nothing if you can’t punch through five layers of canvas at full throttle—that’s where motor efficiency and power output separate hobby sergers from true textile equipment.

Industrial overlock machines deploy servo or clutch motors rated 550W to 750W (up to 1HP), delivering:

- Torque stability for consistent penetration on 12-ounce denim

- Speed control from 200 to over 5000 RPM without power loss

- Energy savings of 60–80% with modern servo technology

- Sewing technology upgrades that cut downtime by 30% through automated tension and predictive maintenance

Direct-drive systems in heavy-duty models eliminate belt loss, pushing efficiency above 80%—sometimes hitting 95%—while intelligent sleep modes slash idle consumption during fabric sewing operations. Understanding the overlock machine basics is vital for peak performance.

Specialized Presser Feet

All that motor muscle still bottlenecks at the contact point—your presser foot—which is why specialized feet designed for thick materials transform brute force into controlled, skip-free stitching across upholstery, leather, and multilayer denim.

Walking feet with dual-action feed dogs prevent fabric shifting during serging, while roller presser foot types glide over sticky vinyl and coated textiles.

Adjustable foot pressure and height let you dial in sewing accuracy for each material, ensuring edge control whether you’re mastering overlock stitch basics or advancing into professional sewing techniques and tips.

Differential Feed for Thick Fabrics

Differential feed mechanisms tackle the engineering challenge that trips up most home machines: synchronized top and bottom fabric movement through two independently controlled feed dog systems that prevent puckering, stretching, and layer misalignment on materials exceeding 12-ounce denim weight.

You’ll adjust the ratio from 0.7 to 2.0 depending on fabric behavior—higher settings gather stretch fabrics while lower ratios flatten seams on rigid canvas.

This fabric feed control gives you mastery over uneven layer management, preventing puckering through ideal settings customized to each heavy fabric adjustment your serger encounters.

Overlock Vs Regular Sewing Machines

Your regular sewing machine handles most tasks just fine, but heavy fabrics? That’s where it hits a wall.

An overlock machine excels in exactly these situations. These machines aren’t interchangeable—they complement each other in garment construction, and knowing which one to reach for makes all the difference when you’re tackling challenging materials.

Here’s how overlockers and standard machines stack up: function, finishing capability, fabric management, and workflow integration.

Function and Stitch Differences

The core distinction between overlock machines and conventional sewing machines centers on their fundamental stitching mechanisms and edge-treatment capabilities. Regular machines create lockstitch construction, while sergers execute overlock stitch types using loopers and multiple threads simultaneously. Differential feed and adjustable stitch length give you mastery over fabric compatibility—from delicate weaves to heavyweight materials requiring specialized overlock techniques and precise thread tension control.

| Feature | Regular Sewing Machine | Overlock Machine |

|---|---|---|

| Stitch Variations | Lockstitch, zigzag, decorative patterns | 3-thread, 4-thread, 5-thread overlock stitch |

| Primary Function | Seam construction through fabric layers | Edge finishing with thread wrapping and trimming |

| Thread Count | 1-2 threads typical | 3-5 threads for reinforced seams |

Edge Finishing Capabilities

Professional edge finishing transforms raw fabric margins into reinforced barriers against unraveling—a capability where overlock machines command absolute authority over conventional equipment. Your serger executes simultaneous edge trimming and thread tensioning operations, wrapping three to five threads around cut edges in one decisive pass. Seam reinforcement through overlock stitching creates durable fabric binding that standard machines can’t replicate without multiple steps.

| Edge Finishing Techniques | Overlock Machine | Regular Sewing Machine |

|---|---|---|

| Edge Trimming | Built-in blade trims during stitching | Requires separate scissors or rotary cutter |

| Thread Coverage | 3-5 thread overlock stitch wraps edges | Zigzag stitch provides minimal edge protection |

| Seam Reinforcement | Loopers create interlocking thread barrier | Single needle penetration, prone to fraying |

| Operation Speed | One-pass edge finishing | Multiple passes required for clean results |

Suitability for Heavy Fabrics

Heavy-duty overlock machines demolish fabric thickness limits that cripple standard sewing equipment. You’ll process denim layers up to four millimeters thick without seam stress resistance failures—capabilities standard machines can’t match when dealing with industrial fabric types like canvas or upholstery project suitability materials. Five-thread overlock stitch configurations deliver the seam security your home decor applications demand, while differential feeds maintain fabric finishing precision across thick textiles. For best results, consider using heavy duty machines that can tackle demanding projects.

| Heavy Fabric Performance | Overlock Machine | Regular Sewing Machine |

|---|---|---|

| Maximum Fabric Thickness | Up to 4mm multi-layer denim | Struggles beyond 2mm layers |

| Industrial Fabric Dealing | Canvas, upholstery, workwear textiles | Limited to medium-weight materials |

| Seam Strength Under Stress | 400-pound tensile thread capacity | Standard thread breaks under heavy load |

Workflow Integration in Garment Making

Your garment assembly line operates like a relay race—overlock machines anchor the finishing leg, turning raw seams into production-ready edges that standard machines hand off but can’t complete.

In garment construction and sewing, you’ll integrate overlockers after primary seam assembly, where they execute seam finishing while your regular machines manage structural joins. This manufacturing optimization approach maintains production planning efficiency—your supply chain flows smoothly when fabric management tasks align with each machine’s specialized function.

| Workflow Stage | Regular Machine Role | Overlock Machine Usage |

|---|---|---|

| Primary Construction | Joins fabric panels, structural stitching | Not applicable |

| Seam Finishing | Limited edge control | Trims, overcasts, prevents fraying |

| Quality Control | Stitch integrity checks | Professional edge finish validation |

Proper overlocker settings during garment construction and finishing guarantee your heavy fabric projects meet quality control standards without workflow bottlenecks.

Choosing The Right Overlocker for Thick Fabric

Finding the right overlocker for heavy fabrics comes down to specs, not luck.

Before you buy, get familiar with motor power, what needles the machine takes, and how its feed system works.

These technical requirements are what separate machines built for thick fabrics from those that’ll choke under pressure.

The following points break down the technical requirements that separate machines built for thick fabrics from those that will struggle under pressure.

Essential Specifications for Heavy Fabric

When hunting for an overlocker that won’t buckle under pressure, look for reinforced metal frames—cast iron or steel construction appears in over 97% of industrial-grade models.

You’ll need motor ratings between 250 and 500 watts paired with servo motors delivering up to 7,000 stitches per minute for consistent stitch quality on heavy fabric. Prioritize 4- or 5-thread configurations and presser foot lifts exceeding 5 mm to manage multi-layer materials up to 14 oz/yd².

Adjustable thread tension controls and differential feed systems guarantee your overlock stitch holds strong, while digital overlocker settings let you dial in fabric thickness tolerances with precision.

Direct-drive systems boost motor efficiency and sewing speed, giving you command over even the toughest textiles.

Needle and Thread Recommendations

Matching the right needle size and thread weight to your fabric gauge isn’t guesswork—it’s the difference between professional seams and a jammed machine halfway through production. Here’s your command protocol for heavy fabric:

- Needle sizes 16/100 to 18/110 pierce dense weaves without deflection or breakage

- Tex 40–70 needle threads and Tex 50–80 looper threads balance stitch quality with fabric compatibility

- Ball-point or wedge-point sewing needles prevent snags in knits and wovens respectively

- Industrial overlock cones (3,000+ yards) eliminate mid-batch threading interruptions

- Pre-tension thread tension dials before threading—prevent needle and looper thread conflicts instantly

Motor Type and Power Needs

Once you’ve nailed needle and thread specs, motor choice becomes your power play—because dragging twelve layers of canvas through a weak clutch motor is like expecting a bicycle to tow a trailer uphill.

Servo motors deliver 35% higher energy efficiency and instant torque control at variable motor speed, letting you adjust power consumption without sacrificing stitch integrity. Your tension dial stays stable, your overlock stitch won’t skip, and electric systems respond instantly to heavy fabric resistance—transforming your sewing machine into a precision instrument.

Fabric Compatibility and Versatility

Real versatility starts when your machine manages everything from ballistic nylon to silk chiffon without swapping out half the parts or guessing at tension dials.

Look for overlock machines with automatic tension systems that adapt across fabric types and material thickness—from woven canvas to stretchy fabric blends.

You’ll expand your sewing techniques and thread options without relearning your overlock stitch settings every time fabric compatibility shifts.

Performance and Efficiency in Industrial Use

When you master proper maintenance and smart automation, you gain the control needed to keep your operation running at peak efficiency.

When you’re running an industrial operation, your overlock machines need to deliver hour after hour without losing steam. You’ll face real challenges—from broken threads to skipped stitches—that can stop production cold if you don’t stay ahead of them.

Understanding how to optimize performance through proper maintenance and smart automation gives you the control to keep your operation running at peak efficiency.

Common Mechanical Challenges

When you’re pushing industrial overlockers through thick textiles, mechanical failures don’t just slow you down—they stop production cold.

Thread breakage hits 30% of heavy fabric operations due to incorrect tension, while needle damage spikes 23% on multilayer materials. Fabric jamming plagues 24% of runs exceeding four layers, and overlock stitch problems from feed system malfunctions disrupt 22% of seams over 350 gsm.

Motor overload, threading errors, and cutting blade misalignment further compromise your weaving and seam quality.

Maintenance and Downtime Reduction

Consistent maintenance schedules cut downtime by 30% and keep your overlock machines running at peak capacity through even the toughest production demands. Preventive Maintenance isn’t optional—it’s your first line of defense against Overlock Stitch Problems and seam failures:

- Regular Servicing every 500 operating hours prevents thread breakage and needle damage

- Thread Management protocols reduce threading errors by monitoring tension calibration

- Machine Calibration weekly ensures blade alignment and differential feed accuracy

Operator Training in sewing techniques and weaving fundamentals transforms your crew into troubleshooting experts who spot issues before they halt production.

Automation and Smart Features

Smart automation transforms manual stitch adjustments into real-time monitoring systems that predict failures before they shut down your production line. Smart Sensors track threading tension and blade wear, while Automated Tension controls prevent Overlocker Stitch Problems across fabric weight shifts.

Predictive Maintenance alerts cut emergency repairs, and Energy Efficiency gains through servo integration give you 35% lower power consumption—proving your overlock machine investment pays for itself.

When you’re buying a heavy-duty overlock machine, the sticker price is just the beginning. You’ll want to account for what it costs upfront, how much it’ll add to your energy bill, and whether financing can help you afford one of these industrial powerhouses.

When you know what you’re spending up front and what you’ll save down the road, you can pick a machine that’ll actually earn its keep.

Investing in a heavy-duty overlock machine means looking beyond the price tag. You’ll need to factor in upfront costs, energy expenses, and how financing options can make these industrial workhorses accessible.

Understanding the financial picture—from purchase price to operational savings—helps you make a choice that won’t just perform well but pay off over time.

Price Range of Heavy-Duty Models

Industrial overlock machines built to manage heavy fabrics usually range from USD 1,300 to USD 2,300 per unit on today’s global market, positioning them as a significant capital investment that demands careful evaluation of your production needs and budget constraints.

Your price point analysis should weigh cost comparison factors like motor type, stitch capacity, and brand reputation—SINGER serger machines and similar heavy-duty models often command premium pricing but deliver fewer overlocker stitch problems.

Market trends show that servo-equipped overlock machines cost more upfront yet reduce long-term operational expenses through enhanced energy efficiency and reliability.

Financing and Leasing Options

You’ll find that leasing and installment payment plans have become powerful financing tools that let you acquire sophisticated overlock machines without draining your capital reserves—a strategy that’s helping small and medium-sized enterprises compete with larger production houses.

These finance options release access to premium SINGER serger machines, PFAFF serger machines, and HUSQVARNA VIKING serger machines through flexible payment terms that align with your cash flow cycles.

Your budget analysis reveals substantial cost savings when you match equipment capabilities to production volume.

Long-Term Savings With Servo Motors

Servo Technology transforms your overlock machine into a powerhouse of Cost Reduction and Energy Efficiency, delivering measurable returns that compound year after year. When you upgrade to servo-equipped PFAFF Serger Machines or HUSQVARNA VIKING Serger Machines, you’re locking in operational advantages that clutch motors can’t match:

- 70% lower energy consumption compared to conventional clutch motors in industrial sewing applications

- Payback period of just 4 years through energy savings alone, with cumulative reductions reaching $500–$1,200 per machine over five years

- 15–20% reduction in unscheduled downtime from reduced maintenance needs and brushless motor durability

- Enhanced precision control that boosts throughput by 8–15% while maintaining consistent overlock stitch quality

Motor Upgrades to servo systems position your operation for Sustainable Manufacturing success, cutting electricity costs by 60–80% while extending equipment lifespan by an estimated 20%—advantages that strengthen your competitive edge in heavy fabric production.

Energy Consumption in Manufacturing

Your overlock machine’s appetite for electricity doesn’t just eat into your monthly utility bill—it devours up to 70% of total energy consumed across your entire apparel manufacturing floor.

That’s why upgrading to servo-driven Sewing Machines delivers Power Efficiency gains of 20–35%, slashing Manufacturing Costs while positioning your textile manufacturing operation for Sustainable Production.

Green Technology investments in energy-efficient overlock systems reduce fabric processing expenses and strengthen your competitive advantage in heavy-duty applications.

Working with heavy fabrics on an overlocker takes more than basic threading and footwork—thick materials demand precise adjustments to your machine’s setup before you can tackle them successfully.

Nail these four adjustments—needle size, thread weight, tension, and feed settings—and you’ll see the gap between clean, professional seams and constant do-overs.

Let’s break down the four adjustments that’ll transform your thick fabric overlocking from frustrating to flawless.

Getting your needle size, thread weight, tension, and feed settings dialed in makes the difference between professional seams and frustrating failures.

Here’s what you need to know to take full control of your overlock work with thick fabrics.

Needle and Thread Selection

Choosing the right needle and thread combination maximizes the full potential of your overlock machine when working with heavy fabrics like denim, canvas, or upholstery material. Proper material selection ensures exceptional stitch quality and fabric compatibility.

Correct needle sizes directly impact seam integrity and reduce costly rework. Here are key considerations:

- Sewing needles: Use size 16/100 or 18/110 needles for thick materials to prevent skipped stitches and needle breakage.

- Needle threads: Match thread weight to fabric—heavyweight polyester or bonded nylon ensures durability in the overlock stitch.

- Looper threads: Select bulkier looper threads for secure edge coverage without compromising threading ease.

Adjusting Tension and Feed Settings

Once you’ve matched needles and thread to your fabric, dialing in the tension and feed settings transforms those components into impeccable, production-ready seams. Mastering tension control and feed adjustment unlocks consistent stitch optimization across denim, canvas, and upholstery weights.

Test your threading and weaving on scraps before committing to production runs.

| Setting | Heavy Fabric Adjustment |

|---|---|

| Needle Tension | Reduce slightly to prevent thread breakage |

| Looper Threads | Increase for secure edge coverage |

| Differential Feed | Set 1.5–2.0 ratio to prevent stretching |

| Stitch Length | Lengthen to 3.5–4mm for thick seams |

| Feed Dogs | Raise pressure for improved fabric management |

Preventing Common Stitch Problems

Even with perfectly calibrated tension and feed, broken threads, skipped stitches, and puckered seams will derail your workflow if you don’t catch the warning signs early.

Monitor thread breakage by inspecting needle condition every few hours—bent or dull needles destroy stitch formation before you notice fabric fraying. Watch for these critical red flags:

- Tension Issues causing looped or tight serging edges

- Stitch Skipping signaling needle-to-looper timing drift

- Seam Puckering revealing excessive differential feed or speed

Address symptoms immediately to maintain impeccable overlock stitch integrity across production runs.

Maintaining Seam Quality and Durability

Seam strength under stress separates a finished garment from a liability claim—every stitch you lay down must hold against wear, washing, and weight without compromise. Lock in seam integrity by maintaining consistent thread tension and verifying stitch consistency during fabric selection.

Test serging edges under load before full production runs—durability testing reveals weak overlock stitch patterns that fail under real-world conditions. Apply proven seam finishing methods and garment sewing techniques to guarantee every seam withstands the demands you’ve engineered it to face.

Professional results with heavy fabrics require more than just a powerful machine—you need deliberate finishing techniques that turn rough edges into polished, lasting work.

These four finishing techniques will take your heavy fabric work from simply functional to truly exceptional.

The difference between amateur and expert outcomes lies in how you manage edge finishing, seam reinforcement, and fabric bulk during the final stages of construction.

Master these four finishing approaches to enhance your heavy fabric projects from functional to impeccable.

Clean Edge Finishing Methods

A perfectly finished edge isn’t just about preventing frays—it’s the hallmark of a craftsman who refuses to let heavy fabric dictate the final outcome.

You control edge trimming through precise fabric cutting and synchronized overlock stitches that seal each seam with authority.

Master thread tensioning to lock your fabric finishing in place, transforming raw edges into professional seam finishing methods that withstand industrial demands.

Your fabric sealing technique determines whether you’re simply sewing or commanding the material itself.

Reinforced Seams for Durability

When heavy fabric threatens to tear free under stress, three interlocking factors—stitch density, thread gauge, and seam reinforcement geometry—become the foundation of durability you can’t afford to compromise.

Your sewing machine’s looper threads must lock together at intervals that prevent fabric cutting under load. Control thread tension to balance fabric strength without distorting the weave.

- Increase stitch density along high-stress zones for enhanced seam reinforcement

- Select heavier thread gauges that match your fabric’s breaking point

- Test overlock stitch configurations through durability testing protocols

- Monitor looper thread alignment to prevent seam failure

- Adjust differential feed to eliminate puckering in reinforced areas

Decorative Overlock Stitches

Beyond pure function, decorative overlock stitches transform raw edges into visual statements—flatlock seams, rolled hems, and wave stitches don’t just secure fabric, they command attention.

You control the aesthetic impact through thread colors that contrast or complement fabric textures.

Master these sewing techniques by adjusting looper threads for precise stitch patterns, turning garment construction into artistry.

Your overlock stitch becomes more than edge finishing—it’s the signature that separates industrial adequacy from outstanding craftsmanship.

Handling Bulk and Layered Fabrics

Thick layers, intersecting seams, and bulky fabric junctures push standard overlock capabilities to their limit—mastering this challenge unlocks flawless finishing on upholstery, outerwear, and multi-ply textile assemblies.

You’ll need to reduce presser foot pressure and slow your sewing machine speed when maneuvering bulk fabric sewing zones. Adjust looper threads to prevent puckering, and guide layered fabric tips manually through thick material management points where differential feed alone won’t suffice—your overlock stitch quality depends on controlled manipulation, not machine force.

Frequently Asked Questions (FAQs)

Can overlock machines handle leather and canvas?

Most industrial overlock machines can tackle leather and canvas, but you’ll need the right needle size, heavy-duty thread, and proper tension adjustments.

Success depends on your machine’s motor power and presser foot pressure for thick material management.

What is the typical lifespan of industrial overlockers?

With proper care, industrial overlockers usually last 10 to 15 years in heavy-duty production environments.

Professional sewing practices and consistent overlocker maintenance extend equipment reliability greatly, ensuring heavy-duty performance throughout the machine’s operational lifespan.

How do you troubleshoot skipped stitches effectively?

Skipped stitches are like red flags waving at you—check your needle first for damage or dullness, then verify thread tension on both needle threads and looper threads.

Fabric preparation matters too; guarantee proper machine calibration for peak stitch quality using this troubleshooting guide for sewing beginners mastering their sewing machine.

Are replacement parts readily available for all brands?

Part availability varies notably by brand. Major manufacturers like Juki MO654DE, Juki MO644D, Brother 1034DX, and Janome MOD8933 offer excellent spare parts support through authorized dealers and online retailers, backed by strong warranty coverage.

What safety certifications should professional models have?

Professional models require UL Certification and CE Marking for Electrical Safety, plus ISO Standards compliance for Textile Engineering applications.

Operator Training documentation and proper Fabric Management and Care protocols protect workers during Sewing Machine operations, ensuring your team masters Sewing Tips and Tricks for Textile and Fabric Crafting safely.

Conclusion

Think of your production line as a high-performance engine—the wrong overlock machine for heavy fabric is the equivalent of cheap spark plugs under sustained load. You’ve seen the mechanical tolerances that separate reliable equipment from costly breakdowns: reinforced needle bars, servo-driven torque management, and differential feeds engineered for 12-ounce canvas.

The machines reviewed here eliminate the fifteen-minute needle-change interruptions that sabotage your output. Choose based on the specifications that match your fabric weight and production volume—your uptime depends on it.

- https://www.linkedin.com/pulse/overlock-machine-market-size-dynamics-insights-strategy-pjbdc

- https://www.maximizemarketresearch.com/market-report/global-heavy-duty-sewing-machines-market/113313/

- https://www.gminsights.com/industry-analysis/industrial-sewing-machine-market

- https://www.verifiedmarketreports.com/product/thread-overlock-sewing-machine-market/

- https://www.ch-sewing.com/news/revolutionizing-the-sewing-industry-the-rise-of-the-full-automatic-serging-4-thread-overlock-sewing-machine-269486.html