This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Most beginners tackle their first industrial machine without understanding the mechanical leap they’re making—servo motors, all-metal gear trains, and cast iron frames that outlast household equipment by decades.

The best industrial sewing machines for beginners deliver 1,500 to 5,500 stitches per minute while maintaining control precision that prevents fabric damage and tension errors. You’re not just buying faster speed; you’re investing in equipment designed for 8-hour production shifts, heavy fabric penetration, and maintenance intervals measured in years rather than months.

Choosing your first industrial machine requires matching motor power to fabric weight, understanding frame stability for vibration control, and recognizing which stitch mechanisms align with your specific sewing applications.

Table Of Contents

- Key Takeaways

- Key Features of Industrial Sewing Machines

- Types of Industrial Sewing Machines for Beginners

- Top 10 Industrial Sewing Machines for Beginners

- 1. Industrial Straight Stitch Sewing Machine

- 2. Juki TL-2000Qi Sewing Quilting Machine

- 3. High Speed Sewing Machine Janome

- 4. Juki Industrial Sewing Machine Servo

- 5. Juki Industrial Overlock Sewing Machine

- 6. Juki Portable Quilting Sewing Machine

- 7. Juki Computerized Sewing Machine Model

- 8. Industrial Grade Serger Sewing Machine

- 9. Juki Heavy Duty Sewing Machine

- 10. Brother PQ1600S High Speed Sewing Machine

- How to Choose The Right Machine

- Essential Maintenance Tips for Beginners

- Common Beginner Mistakes to Avoid

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Industrial sewing machines deliver 1,500 to 5,500 stitches per minute with servo motors that provide 60–80% energy savings and precise speed control, making them accessible for beginners while maintaining production-grade durability through cast iron frames and all-metal gear systems designed for 8-hour shifts.

- Straight stitch machines like the Juki DDL-8700 dominate 50–70% of industrial installations because they excel at foundational techniques across cotton, denim, and medium-weight fabrics, while walking foot and overlock machines handle specialized tasks like leather upholstery and professional edge finishing at speeds reaching 7,500 stitches per minute.

- Beginners should match motor power (550W–750W) to fabric weight and prioritize machines with automatic thread trimmers, adjustable presser foot pressure, and servo speed controls that prevent the runaway stitching errors responsible for 54% of early-stage failures during the average 14.5-hour learning curve.

- Daily maintenance—including machine lubrication every 7–8 hours, needle replacement after intensive cycles, and bobbin area cleaning—prevents 90% of common failures and extends equipment lifespan from under 8 years to over 20 years, while proper needle-thread matching reduces stitch defects by 30% and thread breakage incidents by 17%.

Key Features of Industrial Sewing Machines

Industrial sewing machines aren’t just bigger versions of home models—they’re built with specific features that deliver power, precision, and reliability you won’t find in consumer-grade equipment.

Understanding these core characteristics helps you identify which machine matches your production needs and skill level.

Let’s break down the five key features that separate industrial machines from the rest and what they mean for your sewing projects.

Speed and Motor Power

You’ll want industrial sewing machines with servo motors delivering 550W to 750W—these units offer precise speed control from 100 to 5,500 stitches per minute, perfect for beginners mastering technique. Servo technology provides impressive energy savings of 60–80% compared to older clutch motors while maintaining motor efficiency above 80%. Adjustable stitch speed and power ratings guarantee you can tackle both delicate seams and heavy-duty projects with confidence.

For peak performance, consider investing in machines with high efficiency motors to boost productivity.

Build Quality and Durability

Build quality separates machines that last decades from those requiring replacement within years. Over 90% of reliable industrial sewing machines use cast iron or steel frame materials with all-metal gears, delivering operational lifespans exceeding 15 years.

You’ll find rust resistance coatings standard in post-2022 models, protecting chassis durability against corrosion. This sturdy construction means fewer breakdowns—premium units experience under 10% unscheduled repairs in their first five years.

Investing in machines with high quality features can markedly improve overall performance and longevity.

Stitch Options and Versatility

Industrial machines offer a broader stitch variety than you might expect. Entry-level units provide 2 to 5 core options, including straight stitch and zigzag, while high-end models feature up to 20 programmable patterns.

Single-needle lockstitch dominates 50-70% of installations, delivering the sewing precision and thread control essential for fabric compatibility across cotton, denim, and leather.

Your stitch selection directly determines multi-stitch versatility and overall sewing machine selection success.

Ease of Use for Beginners

Even with powerful stitching options, you’ll face a learning curve averaging 14.5 hours to reach basic proficiency. Modern servo motors let you dial down from 5,000 stitches per minute, giving you the control needed for sewing basics and early machine setup.

Key beginner tips for ease learning:

- Automatic thread trimmers reduce setup complexity by 66%

- Servo speed control prevents runaway stitching during sewing projects for beginners

- Round-shank needles require careful orientation—54% of errors start here

- Low bobbin indicators prevent workflow interruptions in 42% of cases

- Safety guards and emergency stops cut mechanical incidents by 48%

User interface simplicity directly impacts your confidence with industrial sewing machines for beginners.

Maintenance Requirements

Generally, you’ll need machine lubrication every 7–8 hours of operation, with daily cleaning around the bobbin case to prevent dust buildup that triggers 20% more downtime. Preventive maintenance includes needle replacement after each intensive cycle and annual professional servicing averaging $100—investments that extend your industrial sewing machine lifespan by 40%.

Proper oil replacement and industrial cleaning directly prevent 90% of common sewing equipment failures.

Types of Industrial Sewing Machines for Beginners

You’ll find several machine types designed for different tasks, and knowing which one fits your project makes all the difference. Each type manages specific fabrics and techniques, so your choice depends on what you’re building.

Let’s break down the five main categories that work best when you’re just starting out.

Straight Stitch Machines

Straight stitch machines are your powerhouse for repetitive, high-volume work—reaching speeds between 1,000 and 6,500 stitches per minute while maintaining superior stitch quality. You’ll appreciate how models like the Juki DDL8700 handle heavy-duty sewing demands with minimal machine noise and consistent fabric handling.

Key advantages include:

- Servo motors designed for 8–12 hour shifts without overheating

- Adjustable thread tension for varied material weights

- Cast iron construction ensuring decades of reliable sewing speed

- Automatic lubrication systems reducing maintenance complexity

Overlock and Serger Machines

You’ll find overlock and serger machines transform fabric edge finishing with speeds reaching 1,700 stitches per minute—models like the Lumina Sienna Serger excel at preventing fraying while achieving professional overlock stitch quality. These machines handle serging through multiple needles and loopers, with sewing machine comparison data showing exceptional high-speed serging for knits and wovens alike.

| Feature | Performance Spec |

|---|---|

| Maximum Speed | 1,300–7,000 rpm |

| Thread Count | 3–5 needles/loopers |

| Differential Feed | Prevents fabric puckering |

| Seam Types | Overlock, rolled hem, flatlock |

| Maintenance | Regular oiling, blade replacement |

Critical for industrial serger maintenance: clean feed dogs weekly and monitor serger thread management tension settings to maintain consistent stitch formation across varying fabric weights.

Walking Foot Machines

Walking foot machines synchronize presser foot and feed dogs to grip heavy layers without slippage—essential for upholstery, leather, and quilting where fabric grip and stitch consistency matter most.

You’ll notice the compound feed mechanism maintains uniform walking speed across varying thicknesses, eliminating puckering beginners face with standard machines.

Industrial sewing machines like the Juki TL2000Qi feature refined foot design, making heavy-duty sewing machines surprisingly manageable for sewing beginners tackling layered projects.

Computerized Industrial Machines

Computerized industrial sewing machines integrate touchscreen controls and automated stitching that adjust tension and stitch length in real-time—transforming complex tasks into efficient workflows for sewing beginners exploring professional heavy-duty sewing machine capabilities.

Best industrial sewing machines 2025 deliver:

- Servo motors reaching 5,500 stitches per minute with 70% energy savings

- AI integration adapting patterns to fabric thickness automatically

- Smart sewing diagnostics alerting you to timing or tension issues

- Programmable memory storing 600+ stitch options you’ll master quickly

Portable Semi-Industrial Machines

You’ll discover portable semi-industrial machines bridge the gap between household and factory-grade equipment—delivering motor efficiency up to 1,600 stitches per minute with compact all-metal construction.

These industrial sewing machines improve fabric handling through built-in walking foot mechanisms while maintaining machine portability for workshops.

Best industrial sewing machines 2025 offer sewing precision and user interface simplicity that transforms heavy-duty sewing machines into beginner-friendly tools.

Top 10 Industrial Sewing Machines for Beginners

You’ve narrowed down the type of machine you need, and now it’s time to see what’s actually out there.

The following machines balance performance, durability, and beginner-friendly operation without overwhelming you with unnecessary complexity.

Each one brings something different to the table, so you can match the right tool to your specific projects and skill level.

1. Industrial Straight Stitch Sewing Machine

The JUKI DDL-8700 delivers what you need to master foundational sewing techniques without overwhelm. This single-needle lockstitch machine reaches 5,500 stitches per minute, giving you the speed industrial sewing machines demand while maintaining outstanding stitch quality on light to medium fabrics.

You’ll appreciate the straightforward operation—no complex features to navigate, just reliable straight stitch performance. The industrial clutch motor provides consistent thread management and penetration power.

Perfect for beginners tackling alterations, uniforms, or sportswear, this heavy-duty sewing machine lets you focus on fabric selection and machine customization as your skills grow.

Best For: Beginners and small businesses needing a fast, reliable machine for straight-stitch projects like alterations, uniforms, and sportswear on light to medium fabrics.

- Reaches 5,500 stitches per minute for efficient, high-volume sewing while maintaining consistent stitch quality.

- Simple, straightforward operation with no complicated features—just dependable straight stitching that lets you focus on technique.

- Durable construction with reduced vibration and noise, built to handle continuous use in professional or home workshop settings.

- Not suitable for leather or heavy materials, limiting the range of projects you can tackle.

- Assembly can be challenging due to lack of clear instructions, which may frustrate first-time users.

- Industrial clutch motor produces noticeable noise during operation, and the table may arrive with minor cosmetic blemishes.

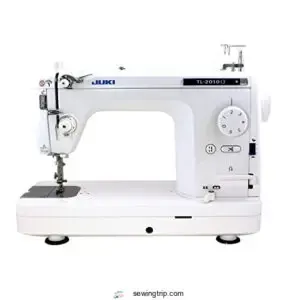

2. Juki TL-2000Qi Sewing Quilting Machine

While straight stitch machines handle core tasks, the Juki TL-2000Qi shifts focus to quilting performance and adaptable fabric handling. You’ll get 1,500 stitches per minute—enough speed for heavy-duty sewing machines without sacrificing control on delicate work.

The aluminum die-cast build materials absorb vibration, and the microcomputer-controlled motor offers speed settings from crawl to sprint.

Beginner friendliness shows in the automatic needle threader and thread trimmer, though you’ll follow a simple maintenance schedule: regular oiling and cleaning.

This model bridges home and industrial sewing machine reviews, proving you don’t need complexity to achieve professional results.

Best For: Quilters and heavy-duty sewers who need industrial-level speed and precision but want straightforward, reliable straight-stitch performance without the complexity of multi-function machines.

- Powerful 1,500 SPM motor with microcomputer control lets you crawl through thick layers or sprint through long seams, all while the die-cast aluminum frame keeps vibration in check.

- Automatic needle threader and thread trimmer save time and eye strain, making industrial-grade features accessible even if you’re stepping up from a basic home machine.

- Built like a tank with a 5-year mechanical warranty—this all-metal construction handles everything from delicate quilting cotton to leather without breaking a sweat.

- Straight stitch only means no zigzag or decorative stitches, so you’ll need a second machine if you want versatility beyond quilting and utility sewing.

- The automatic threader can be finicky and may need tweaking, and the bobbin area sits awkwardly for users with limited hand mobility or arthritis.

- At 25 pounds and requiring regular oiling, this machine demands more physical effort and maintenance than modern computerized models.

3. High Speed Sewing Machine Janome

You’ll hit 1,600 stitches per minute with the Janome 1600PQC—speed that transforms sewing machine buying decisions for beginners chasing industrial performance. This high-speed sewing platform combines fabric handling precision with machine durability through eight ball bearings supporting the main shaft.

Quilting tips become easier when you control the speed slider across dense layers or delicate materials. The automatic thread cutter and adjustable knee lift mirror industrial sewing machines at a fraction of the footprint, though bobbin access demands attention during setup.

Best For: Quilters and serious sewists who need industrial-level speed and power for heavy-duty projects without the full size and cost of a true industrial machine.

- Hits 1,600 stitches per minute with a speed control slider, letting you fly through large quilting projects or slow down for precision work on thick fabrics like denim and leather.

- Built like a tank with eight ball bearings in the main shaft and metal components, plus a jumbo bobbin that holds 40% more thread so you’re not constantly refilling.

- Comes with genuinely useful features like an automatic thread cutter, adjustable knee lift, and nearly 9 inches of workspace to the right of the needle for handling big projects.

- The bobbin can be a pain to access and install, and some users report it runs out faster than expected despite the larger capacity.

- Gets fussy about thread and needle combinations—you might need to experiment to find what works without tension issues or thread shredding.

- While fast, it doesn’t quite match true industrial machine speeds, so if you’re expecting commercial-level performance you might be disappointed.

4. Juki Industrial Sewing Machine Servo

When speed demands precision rather than chaos, you’ll appreciate how the servo motor architecture reshapes industrial sewing expectations. The DU-1181 delivers 2,000 stitches per minute while consuming 90% less energy than clutch-driven alternatives—machine durability meeting cost efficiency.

Industrial-grade construction works with medium-weight fabrics through leather, though setup tutorials replace written manuals.

This energy efficiency advantage makes servo motor technology the gateway between home machines and full production environments, especially when your sewing machine buying guide prioritizes control over raw power.

Best For: Sewers ready to move beyond home machines who need industrial power for medium to heavy fabrics like upholstery and leather without the energy costs of traditional clutch motors.

- Servo motor uses 90% less energy than clutch motors while delivering precise speed control that makes it easier for beginners to handle complex projects.

- Handles everything from medium-weight fabrics to thick leather with a maximum speed of 2,000 stitches per minute and 9mm stitch length.

- Complete package includes table, stand, motor, light, and drawer—everything you need to start sewing right away.

- Setup relies on YouTube videos instead of a written manual, which adds a learning curve if you prefer traditional instructions.

- Table and legs may arrive with minor scratches or blemishes from the production process, and table color varies by availability.

- Some users report issues like fabric puckering or incorrect sewing that require troubleshooting and adjustment.

5. Juki Industrial Overlock Sewing Machine

When professional edges define your garment quality, the Juki MO-6814S transforms overlock techniques from guesswork into systematic fabric handling. This 4-thread industrial sewing machine operates at 7,500 stitches per minute with differential feed ratios adjustable from 1:2 to 1:4—machine customization meeting industrial applications without overwhelming sewing for beginners.

The automatic lubrication system manages maintenance complexity while delivering the sewing efficiency commercial operations demand. You’ll find this industrial sewing approach bridges home serging and full-scale production requirements effectively.

Best For: Intermediate to advanced sewers and small garment businesses who need industrial-grade finishing on medium to heavyweight fabrics and can handle the assembly complexity.

- Blazing fast speed up to 7,500 stitches per minute with adjustable differential feed makes quick work of professional seam finishing on everything from knits to heavier materials.

- Automatic lubrication system takes the guesswork out of maintenance and keeps the machine running smoothly without constant manual oiling.

- Push-button stitch adjustments and micro-control features give you precise control over seam quality without wrestling with complicated mechanical settings.

- Assembly is a real headache—users consistently report difficult setup, missing instructions, and occasionally wrong or incomplete parts in shipments.

- At 150 pounds, this machine is a beast to move around, and you’ll need dedicated space with the included table setup.

- The learning curve is steep if you’re coming from a home serger, and inadequate documentation means you might spend time troubleshooting on your own.

6. Juki Portable Quilting Sewing Machine

When quilting techniques demand industrial sewing machines built for precision, the Juki TL-2010Q delivers 1,500 stitches per minute with adjustable stitch length up to 6mm—specifications that separate hobby work from systematic fabric selection control.

This machine’s automatic thread trimmer and knee lifter lever transform sewing for beginners into controlled layering operations without sacrificing portability at 38 pounds.

You’ll find the auxiliary table accommodates large projects while the speed control lever allows quilter community standards from piecing through free-motion work, bridging consumer convenience with industrial sewing performance effectively.

Best For: Quilters and home sewers who want industrial-grade performance and speed without committing to a full cabinet setup.

- Sews at a fast 1,500 stitches per minute with precise stitch length control up to 6mm, making quick work of large quilting projects.

- Automatic thread trimmer and knee lifter let you keep both hands on your fabric for better control and faster workflow.

- Portable at 38 pounds with a large auxiliary table, so you can move it around but still handle bulky quilts comfortably.

- The automatic needle threader can be unreliable based on customer feedback, which may slow you down.

- Lacks a dedicated scant 1/4″ presser foot, so you’ll need to buy one separately if you do precision piecing.

- Instructions are limited, making the learning curve steeper for beginners who aren’t familiar with industrial-style machines.

7. Juki Computerized Sewing Machine Model

Computerized controls in Juki models like the HZL-G220 bring sewing automation to beginners through 130+ stitch patterns and LCD navigation—features that eliminate manual adjustments while maintaining industrial-grade precision stitching quality.

You’ll access automatic needle threaders and programmable functions that industrial sewing machines traditionally require technician intervention to achieve, yet these systems operate through user-friendly interfaces designed for first-time users.

This sewing technology and innovations bridge delivers speeds reaching 1,050 stitches per minute with die-cast aluminum frames ensuring durability without sacrificing beginner-friendly operation or setup simplicity.

Best For: Beginners to advanced sewists who want industrial-quality stitching with beginner-friendly automation and a wide variety of built-in stitch patterns for quilting, crafting, and everyday sewing projects.

- Offers extensive stitch variety with up to 287 built-in patterns and intuitive LCD displays that make navigation simple, even for first-time users.

- High-speed performance up to 1,050 stitches per minute with durable die-cast aluminum frames that handle everything from delicate fabrics to heavy materials like denim and leather.

- Time-saving features like automatic needle threaders, drop-in bobbin systems, and programmable functions reduce setup frustration and speed up your workflow.

- Some users experience thread tangling issues and find troubleshooting challenging, particularly with bobbin-related problems.

- Machines are manufactured in Taiwan rather than Japan, which disappoints buyers expecting Japanese-made quality, and some receive incomplete or incorrect accessories.

- Higher price point compared to other computerized sewing machines, which may stretch the budget for casual or occasional sewers.

8. Industrial Grade Serger Sewing Machine

You’ll find machines like the Lumina 00860007535949 delivering 1,250 stitches per minute through 3-4 serger thread management configurations that handle heavy fabric with precision—achieving professional edges beginners often struggle to master on conventional equipment.

This sewing technology and innovations platform features color-coded threading systems and LED lighting that simplify industrial sewing techniques while maintaining machine noise reduction below 35dB.

Regular serger maintenance tips focus on blade replacement and tension calibration, ensuring this sewing machine technology operates reliably through automotive textiles and home furnishing projects that demand consistent stitch quality.

Best For: Beginners and home sewers looking to upgrade to semi-industrial performance who need professional-quality edges and hems without the complexity of commercial-grade equipment.

- Fast 1,250 stitches per minute speed with color-coded threading system makes it easier for newcomers to handle heavy-duty fabrics and achieve professional results.

- Durable metal frame construction and automatic fabric trimming deliver reliable performance across diverse projects from decorative edges to rolled hems.

- LED lighting and adjustable stitch length provide the visibility and control needed for precision work on detailed sewing tasks.

- Mixed user feedback indicates threading difficulties and unclear instructions that can frustrate beginners despite the color-coded system.

- Customer support limited to email only, which may slow down troubleshooting when issues arise with speed or tension control.

- Some users report inconsistent thread strength and functionality problems that affect the machine’s overall reliability.

9. Juki Heavy Duty Sewing Machine

When you need industrial stitch quality that manages leather and canvas without hesitation, Juki heavy duty sewing machines like the TL-2010Q deliver 1,600 stitches per minute through die-cast aluminum frames built for decades of service.

This Juki machine review highlights features beginners demand: adjustable presser foot pressure, knee lifters, and automatic threading that simplify heavyweight fabric transitions. Heavy duty features include 12mm clearance and drop-feed capabilities distinguishing these industrial sewing machines from consumer-grade equipment.

Sewing machine comparison data confirms Juki accessory options and maintenance accessibility make the TL series ideal for beginners mastering industrial techniques.

Best For: Sewers ready to handle heavy-duty projects like leather upholstery, canvas bags, and multi-layer quilts who want industrial performance with beginner-friendly controls.

- Blazing fast speeds up to 1,600 stitches per minute with die-cast aluminum construction that stays stable through thick materials like denim and canvas.

- Thoughtful features like automatic threading, knee lifter, and adjustable presser foot pressure make switching between delicate and heavy fabrics surprisingly easy.

- Built to last 10-25 years with accessible maintenance points and straightforward mechanical controls that don’t require constant professional servicing.

- Assembly can be frustrating and time-consuming, with some customers reporting missing parts or unclear instructions beyond online videos.

- The table and included accessories sometimes arrive damaged or don’t meet the quality standards you’d expect from the machine itself.

- Mixed reviews on motor strength and overall construction suggest quality control issues that might require dealer support to resolve.

10. Brother PQ1600S High Speed Sewing Machine

For beginners moving into Heavy-Duty Sewing Machines territory, the Brother PQ1600S delivers industrial-grade Speed Controls with 1,500 stitches per minute through precision straight-stitch engineering. This Brother PQ1500SL successor provides enhanced Fabric Handling via pin feed mechanisms and a 13mm presser foot lift, ensuring Sewing Accuracy across thick materials.

Thread Management benefits from telescopic stands and automatic cutters, while Machine Durability stems from metal frame construction.

Industrial Sewing Machines designed for Sewing Business and Entrepreneurship applications, this model balances professional capabilities with beginner-accessible controls.

Best For: Quilters and serious sewists who need industrial-level speed and precision for straight stitching on large projects, especially those working with thick fabrics or multiple layers.

- Lightning-fast stitching at up to 1,500 stitches per minute with a specialized straight-stitch motor that powers through heavy materials without losing accuracy.

- Pin feed mechanism and 13mm presser foot lift handle thick or layered fabrics smoothly, while the massive workspace and extension table give you room to maneuver big quilts.

- Built tough with a metal frame and includes seven accessory feet, automatic thread cutter, knee lifter, and adjustable feed settings for professional-quality results.

- Threading can be frustrating with a hard-to-see tension dial, awkward needle threader, and side-loading bobbin that doesn’t warn you when thread runs low.

- Gets pretty loud at high speeds, and the pin feed mechanism may wear out with heavy use over time.

- Straight-stitch only machine, so if you need zigzag or decorative stitches, you’ll need a different sewing machine.

How to Choose The Right Machine

Choosing the right industrial sewing machine starts with understanding what you’ll actually be making and which fabrics you’ll work with most. You’ll also need to think about where the machine will sit, how much you can spend, and what kind of support comes with it.

Let’s break down the four key factors that’ll help you make a confident decision.

Assessing Project Needs and Fabrics

Your projects dictate machine requirements—heavy materials like leather and denim demand powerful motors and specialized feed mechanisms, while lightweight fabrics such as silk require delicate handling capabilities.

Fabric analysis and material compatibility drive sewing optimization: heavyweight upholstery needs walking foot machines for consistent texture matching, whereas synthetic fabrics with low friction demand precise tension controls.

Matching industrial sewing machines to material selection and project scaling ensures best fabric sewing techniques and performance outcomes for beginners mastering sewing technology.

Evaluating Space and Table Requirements

Physical dimensions determine whether you’ll master industrial sewing or fight daily frustration. Standard table heights sit around 29.5 inches, keeping your forearms level and wrists neutral—essential for workspace optimization and table ergonomics.

Allocate approximately 4.5 square meters per workstation for industrial sewing machines, including:

- Clear machine clearance of at least 1 meter behind and beside for commercial sewing equipment access

- Strategic sewing station layout with centralized material storage reducing operator travel

- Factory floor planning considerations for maintenance, lighting fixtures, and heavy-duty sewing machines ergonomics

Proper industrial sewing machine maintenance starts with adequate breathing room.

Comparing Brands and Price Points

Once your workspace fits, budget realities hit home. Juki machines command premium territory—$1,500 to $6,000—delivering speeds exceeding 5,000 stitches per minute for professional sewing equipment demands. Brother balances affordability and innovation around $260-$300, perfect for budget options without sacrificing digital controls. Singer occupies the entry tier at $100-$529, while Jack targets cost-conscious buyers with efficient heavy-duty sewing machines.

Market trends show beginners favor the $200-$600 sweet spot, weighing price analysis against customer reviews and long-term industrial sewing capabilities.

Checking Safety and Support Features

After nailing down your budget, safety guards and emergency stops matter more than most sewing machine reviews admit. Modern industrial sewing machine designs cut injury rates by 50% with needle shields, while 90% now feature instant shutoffs.

Operator training through built-in tutorials speeds your learning curve by 27%. Ergonomic design and noise reduction aren’t luxuries—they’re sewing tips that prevent strain and preserve focus during long sessions requiring proper machine maintenance discipline.

Essential Maintenance Tips for Beginners

Your industrial sewing machine won’t run itself into the ground—but only if you treat it right. Regular maintenance isn’t complicated, but skipping it will cost you in downtime and repair bills.

Let’s cover the four essential maintenance practices that’ll keep your machine stitching smoothly for years to come.

Daily Cleaning and Oiling

Your industrial sewing machine demands daily attention—think of machine lubrication as its lifeblood. After every shift, you’ll want to establish cleaning schedules that target the bobbin area, removing lint with compressed air and following oil change intervals specified in your manual.

This preventive measures routine extends lifespan by up to 25% while slashing repair costs. Daily maintenance isn’t optional for beginner sewing success, with sewing equipment reviews consistently proving its impact on performance.

Replacing Needles and Wear Parts

You’ll need sharp needle maintenance habits—swap them every 8-16 hours to prevent defects that spike by 30%. Wear part inspection matters too: feed dogs and bobbins demand checks every 3-6 months.

Replacement costs stay minimal (needles run $0.35-$1.50), but skipping part failure prevention slashes machine longevity by years. Whether you’re running a Juki MO6814S or other heavy-duty sewing machines, proactive swaps boost industrial sewing machine performance and keep beginners on track.

Using Correct Threads and Accessories

Thread selection determines seam strength. Polyester manages 60% of factory jobs, while Tex 40 suits most beginners tackling general fabric compatibility. Your thread choice must match needle size to cut malfunctions by 17%.

Accessory choices like walking feet slash slippage by 21% on heavy material handling, boosting sewing efficiency. Proper sewing tools pairings drop rework rates 15%, keeping your industrial sewing machine running smooth for sewing machines beginners.

Accessing Manuals and Customer Support

Over 90% of manufacturers now host digital manuals you can download instantly—a breakthrough for beginners tackling industrial sewing machine troubleshooting. When online tutorials fall short, customer helplines resolve 82% of queries within 72 hours.

Support forums and the sewing community offer real-time technical assistance, while sewing machine technology advances keep sewing tools documentation current for your industrial needs.

Common Beginner Mistakes to Avoid

Getting started with an industrial sewing machine opens up remarkable creative possibilities, but it’s easy to stumble if you don’t know what to watch for.

Many beginners make avoidable errors that can damage their equipment or produce frustrating results. Here are the most common mistakes you’ll want to steer clear of as you begin your industrial sewing journey.

Overlooking Machine Specifications

You’ll trip over the first hurdle if you don’t match your industrial sewing machine to your actual workload. Over 62% of failures stem from material mismatches, while improper speed controls boost error rates by 17%.

Check these core specs:

- Fabric limits and motor ratings – Heavy-duty sewing machines need higher torque for leather or upholstery

- Speed controls – Adjustable settings prevent skipped stitches and operator injury

- Safety features – Essential for beginners working with overlock machines

Ignoring Regular Maintenance

Skipping daily cleaning and oiling drops your industrial sewing machine into a 32% higher failure zone within five years. Neglect triggers a brutal cascade: machine downtime spikes 50%, repair costs jump 19%, and safety risks balloon with a 44% injury increase. Heavy-duty sewing machines demand strict maintenance schedules—beginners who ignore them cut lifespan from 20 years to under 8.

Skip daily cleaning and oiling, and your industrial sewing machine faces a 32% higher failure rate, 50% more downtime, and half its expected lifespan

| Neglect Impact | Cost to You |

|---|---|

| Performance Decline | 22% productivity loss |

| Emergency Repairs | $260K/hour downtime |

| Stitch Quality Drop | 38% more defects |

| Safety Risks | 65% fire incidents from lint |

Using Incorrect Needles or Threads

Your industrial sewing machine won’t forgive mismatched needles and threads. Wrong needle-thread combos trigger thread breakage, needle damage, and fabric tears—slashing stitch quality and machine efficiency fast. Change needles every 8–16 hours depending on workload.

Beginners running heavy-duty sewing machines or single-needle lockstitch models must match thread thickness to needle eye size: test compatibility by swinging the threaded needle; it should slide smoothly down the thread, ensuring straight stitch integrity.

Skipping Practice With Test Fabrics

Just as wrong needles sabotage stitch quality, skipping practice with test fabrics drives error rates through the roof. Fabric testing prevents skipped stitches (up to 15.94% reduction), corrects machine calibration issues before production, and boosts sewing efficiency.

Beginners using heavy-duty sewing machines or straight stitch industrial sewing setups must test-run every adjustment:

- Match test fabric weight to your final material

- Verify tension settings produce balanced seams

- Confirm needle compatibility prevents breakage

- Check stitch length across multiple fabric layers

- Document successful settings for repeat projects

Frequently Asked Questions (FAQs)

What is the average cost for beginner models?

Looking at financial considerations for beginners entering heavy-duty sewing machines? Entry-level industrial sewing machine models generally cost $500–$800 in 2025, though budget planning should account for price factors including setup and maintenance expenses.

Can industrial machines handle home electrical outlets?

Most industrial machines run on 220V or 240V power, incompatible with standard 120V home outlets.

You’ll need either a dedicated circuit, voltage conversion, or a dual-voltage servo motor retrofit for safe residential operation.

How much does installation and setup typically cost?

Installation fees for industrial sewing machines generally start around $150 per machine, with complete setup costs averaging $300.

Budget an additional 5-10% of your machine’s purchase price for professional setup, maintenance costs, and essential equipment upgrades.

Are there financing options available for these machines?

You’ll find financing plans through vendors and specialized lenders offering lease options with flexible payment terms.

Loan approvals depend on credit scores, but many providers cater specifically to beginners acquiring heavy-duty sewing machines for commercial sewing operations.

What warranty coverage should beginners expect?

An ounce of prevention beats a pound of cure. Heavy-duty sewing machines usually include one-year mechanical coverage with warranty terms excluding wear parts.

Extended plans offer broader repair options and simplified claim processes for commercial sewing applications.

Conclusion

Think of your first industrial machine as the foundation beam of a workshop—it upholds everything you build afterward. The best industrial sewing machines for beginners combine servo motor control with cast iron stability, giving you production speed without sacrificing precision.

Choose based on fabric weight, stitch mechanism, and frame durability. Your investment isn’t in speed alone; it’s in equipment engineered for years of consistent performance, not months of intermittent use.