This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A single production bottleneck can cost an embroidery shop $500 to $2,000 per day in missed deadlines and lost contracts. The difference between profit and loss often hinges on one decision: selecting a machine that matches your production demands without draining capital on unused capacity.

Commercial embroidery machines now deliver 1,000 to 3,000 stitches per minute with precision tolerances within ±0.05 mm, but speed means nothing if thread breaks halt your workflow or mechanical failures consume your maintenance budget.

We’ve analyzed the top four commercial systems based on stitch performance, automation features, durability benchmarks, and real-world operating costs to help you identify which machine delivers the highest return on investment for your specific production volume and business model.

Table Of Contents

Key Takeaways

- Commercial embroidery machines operating at 1,000–3,000 stitches per minute with precision tolerances within ±0.05 mm directly impact profitability, as production bottlenecks can cost shops $500–$2,000 daily in missed deadlines and lost contracts.

- Multi-needle systems with 10–15 needles and automatic color change functions reduce operator intervention by 35 minutes per 1,000 stitches while maintaining stitch quality within ±1.5%, making them essential for scaling production efficiency.

- Leading commercial machines achieve 98–99.8% uptime through preventive maintenance every 200–400 operating hours, with annual maintenance costs running 3–8% of purchase price to sustain equipment longevity and minimize unexpected breakdowns.

- Your ROI calculation should target an 18–36 month payback period by matching machine capacity to actual production volume, with financing options reducing upfront costs by 20–40% on equipment investments ranging from $25,000–$60,000.

Top 4 Commercial Embroidery Machines Reviewed

You’re here because you need a machine that won’t slow down when orders stack up. The models we’ve selected represent the strongest performers in commercial embroidery today—machines that balance speed, precision, and reliability without compromise.

Let’s break down what sets each one apart and which might be the right fit for your operation.

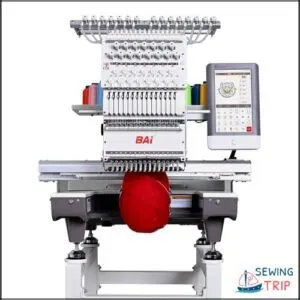

1. Commercial Embroidery Machine System

System integration defines modern commercial embroidery machines—you’re looking at multi-needle platforms where embroidery software, automated backup, and network security converge into a single production powerhouse. These systems pair sturdy hardware with sophisticated connectivity, letting you manage queues across Ethernet or Wi-Fi while machine calibration maintains ±0.2 mm precision.

When evaluating commercial embroidery machine reviews, prioritize models offering real-time diagnostics and cloud-based dashboards—they cut unplanned downtime by 10–20% and transform your embroidery machine into a responsive, data-driven asset.

Best For: Small to mid-sized embroidery shops and entrepreneurs who need professional multi-color capabilities with a large work area but don’t require multi-head industrial setups.

| Number of Needles | 15 |

|---|---|

| Max Speed | 1200 SPM |

| Embroidery Area | 20×14 inches |

| Touch Screen | 10 inch |

| WiFi Connectivity | Yes |

| Automatic Color Change | Yes |

| Additional Features |

|

- 15-needle system with a huge 20×14″ embroidery area gives you serious design flexibility and lets you tackle everything from hats to jackets without constant repositioning.

- 1200 SPM max speed and intuitive 10″ touchscreen with step-by-step guidance mean you can ramp up production quickly even if you’re still learning the ropes.

- Wi-Fi and USB connectivity plus cloud platform support make file transfers easy and keep you connected to design resources and updates.

- At 250 lbs, it’s a heavy piece of equipment that needs dedicated space and careful setup—not something you can move around easily.

- Learning curve for operation and maintenance means you’ll invest time upfront, and oil maintenance is an ongoing requirement to keep it running smoothly.

- Customer support operates across time zones, so getting real-time help when you hit a snag might involve some waiting.

2. Smart Commercial Embroidery Machine

Machine learning elevates the Smartstitch S-1001 into a category of its own—smart stitching algorithms adjust tension and speed on-the-fly, giving you automated embroidery that conforms to denim, canvas, leather, and other sophisticated materials without manual recalibration.

With 10 needles and a 1,200 SPM ceiling, this commercial embroidery machine delivers reliable throughput for commercial applications while a 7″ touchscreen and laser positioning keep setup straightforward.

When you scan embroidery machine reviews, the S-1001 consistently earns praise for balancing automation with hands-on control.

Best For: Small business owners and serious hobbyists who need professional-quality embroidery with automated features but don’t want the complexity or price tag of a full industrial setup.

| Number of Needles | 10 |

|---|---|

| Max Speed | 1200 SPM |

| Embroidery Area | 9.5×14.2 inches |

| Touch Screen | 7 inch |

| WiFi Connectivity | No |

| Automatic Color Change | Yes |

| Additional Features |

|

- Smart algorithms auto-adjust tension and speed for different fabrics like denim, canvas, and leather—no constant fiddling with settings between projects.

- 10-needle system with 1,200 SPM gives you solid commercial speed and minimal color changes, so you can knock out multi-color designs without babysitting the machine.

- Laser positioning and a 7″ touchscreen make setup quick and intuitive, even if you’re still learning the ropes.

- 93 pounds and a 25 x 34 x 33 inch footprint mean you need dedicated space—this isn’t something you’ll tuck in a closet between uses.

- Requires regular maintenance like lubrication every 100–200 hours and daily lint cleaning to keep things running smoothly.

- Learning curve can be steep for first-timers, and you’ll need to keep all original packaging if you want the option to return it.

3. Smartstitch Commercial Embroidery Machine

If you want needle count that scales with demand, the Smartstitch S-1501 brings 15 needles and a 14″×20″ embroidery area—key factors in any machine comparison. You’ll hit 1,200 SPM on varied embroidery techniques, from denim to leather, while the 12″ touchscreen and WiFi simplify product customization.

Commercial embroidery machines like the S-1501 support business scaling through automated color change and laser positioning, and embroidery machine reviews highlight its 270° cap system for 3D hats—a cost analysis advantage when ROI depends on versatility and uptime.

Best For: Small business owners and entrepreneurs looking to start or expand an embroidery operation with professional-grade multi-needle capability and large work area.

| Number of Needles | 15 |

|---|---|

| Max Speed | 1200 SPM |

| Embroidery Area | 14×20 inches |

| Touch Screen | 12 inch |

| WiFi Connectivity | Yes |

| Automatic Color Change | Yes |

| Additional Features |

|

- 15-needle setup with automatic color switching cuts down operator time and handles complex designs without constant babysitting

- 14″×20″ embroidery field and 270° cap system let you tackle everything from oversized jacket backs to 3D hats in one machine

- 1,200 SPM speed with laser positioning delivers consistent, high-quality stitching on tough materials like denim, canvas, and leather

- 209-pound weight means you’ll need help (or a forklift) to move it, and delivery can be tricky

- Beginners may feel overwhelmed by the feature set and need time to learn the controls and setup process

- Return policy requires keeping all original packaging intact, which takes up space and adds hassle if you’re not sure it’s the right fit

4. Smart Commercial Embroidery Machine System

For shops prioritizing machine integration and system optimization, the Smartstitch S-1001 delivers smart embroidery through ten needles and automated production workflows. You’ll run commercial upgrades at 1,200 SPM across a 9.5″×12.6″ field—compact yet capable for startup ventures or established operations adding capacity.

The 10″ LCD touchscreen and WiFi enable rapid design transfer, while automatic color change cuts manual intervention.

Commercial embroidery machines in this class balance affordability with features that support weaving flat goods, caps, and garments without sacrificing precision.

Best For: Small embroidery businesses and startups looking for an affordable multi-needle machine that handles commercial workloads without the complexity of industrial systems.

| Number of Needles | 12 |

|---|---|

| Max Speed | 1200 SPM |

| Embroidery Area | 9.5×12.6 inches |

| Touch Screen | 10 inch LCD |

| WiFi Connectivity | Yes |

| Automatic Color Change | Yes |

| Additional Features |

|

- High-speed operation at 1,200 SPM with 12-needle automatic color change cuts production time and keeps projects moving without constant manual swaps.

- Large 9.5″×12.6″ embroidery field handles most custom jobs—from T-shirts and hats to bags—while staying compact enough for home workshops.

- WiFi connectivity and touchscreen interface make design transfers quick and painless, so you spend less time fighting with files and more time stitching.

- Steeper learning curve for beginners means you’ll need to invest time in setup and training before hitting full productivity.

- Technical support can be slow to respond, which is frustrating when you’re stuck mid-project and need answers fast.

- You must keep all original packaging and accessories if you ever need to return it, which eats up storage space in smaller shops.

Key Features of Leading Commercial Machines

When you’re comparing commercial embroidery machines, the difference between a solid performer and a revolutionary comes down to specific features that directly impact your output and profitability.

Understanding these capabilities helps you match machine specs to your actual production demands. Let’s break down the five critical features that separate leading commercial units from the rest of the pack.

High-Speed Stitching Capabilities

High-speed stitching separates hobbyist equipment from serious industrial sewing solutions. Commercial embroidery machines deliver 1,000–3,000 stitches per minute, with top models sustaining above 2,000 SPM through optimized thread management and needle optimization. That translates to over 40,000 stitches per hour on banner runs—production efficiency that directly impacts your bottom line. Understanding AP study resources can help improve overall operational efficiency.

- Stitch speed scales with multi-needle setups and firmware that keeps high-speed embroidery consistent across large designs

- Fabric handling improves when machines maintain tolerance during continuous 8–12 hour shifts

- Laser positioning enhances accuracy even at peak throughput, ensuring quality never lags behind speed

Multi-Needle and Color Change Functions

You’ll realize dramatic time savings with multi-needle embroidery machines that handle 6–24 needles per head, enabling automatic color change across 12+ palettes. Commercial embroidery machine setups featuring color sequencing reduce changeover by 35 minutes per 1,000 stitches.

Thread management automation cuts waste 9–12% per shift while maintaining stitch quality within ±1.5%, ensuring needle optimization and high-speed embroidery consistency across industrial sewing solutions.

Effective research output analysis is essential for optimizing embroidery machine performance.

Large Embroidery Area and Design Flexibility

You’ll command embroidery fields spanning 360 × 460 mm—260% more usable area than standard frames—unlocking large format capabilities for oversized logos and banners.

Commercial embroidery machine hoop systems support design scaling across 3+ frame sizes with ±0.5 mm edge-to-edge precision, while digitizing software optimizes fabric handling for soft signage up to 1.5 meters wide, giving you unparalleled creative range in commercial embroidery machines comparison.

Advanced Connectivity and Operating Systems

You’ll tap into real-time production visibility when 92% of modern commercial embroidery machines deliver integrated Ethernet connectivity and Wi-Fi embroidery for remote monitoring.

Cloud integration enables you to centralize pattern management across floors, while 83% of automated embroidery systems push firmware updates over-the-air—slashing downtime by 18 minutes per job and keeping your digital embroidery solutions aligned with evolving embroidery technology trends.

Durability and Maintenance Requirements

You’ll protect your investment when top commercial embroidery machine models demonstrate 12,000–24,000-hour MTBF ratings and steel chassis that absorb vibrational stress.

Preventative embroidery machine maintenance every 100–300 hours cuts unexpected breakdowns by 40%, while monitoring wear patterns on spindles and hooks sustains machine longevity.

Annual maintenance costs run 3–8% of purchase price—downtime reduction and predictable repair options keep your embroidery business management lean and your industrial sewing machines running at 98% uptime.

Annual maintenance runs 3–8% of purchase price, but keeps your machines at 98% uptime with predictable repair costs

Performance Benchmarks and Industry Standards

When you’re investing in a commercial embroidery machine, understanding industry benchmarks separates a smart purchase from an expensive mistake. The numbers behind stitch speed, needle capacity, automation, and efficiency define what your machine can actually deliver in a production environment.

Let’s break down the key performance metrics that matter most for your bottom line.

Stitch Speed and Production Efficiency

When you’re chasing efficiency gains in high-speed embroidery, production metrics matter. Top commercial embroidery machines clock 800–1,200 stitches per minute under real workloads, with industrial sewing systems hitting 1,500 SPM at peak.

Speed settings paired with automatic color change and thread management reduce cycle times by 15–35%, while stitch optimization delivers up to 72,000 stitches per hour across multi-head setups—turning ambition into output.

Needle Count and Precision Tolerance

Beyond raw speed, your commercial embroidery machine’s needle calibration determines stitch accuracy within ±0.05 mm over standard areas. Multi-needle systems with 15–50 needles rely on thread tension and embroidery alignment to hold ±0.1 mm tolerances across color changes.

Industrial sewing technology using fabric stabilization and weekly calibration delivers precision embroidery at under 0.2 mm placement error—real mastery in embroidery machine features.

Automation Features for Productivity

Precision sets the stage—automation multiplies your output. Modern commercial embroidery machine systems embed thread trimming, auto feeder synchronization, and predictative maintenance routines that slash downtime by up to 41% through remote monitoring. You’ll see:

- Autonomous thread trimming and bobbin changes in 82% of top-tier units

- Auto-palletized color swaps under two seconds

- Real-time dashboards tracking stitch rate and thread consumption

- Wireless firmware updates eliminating service calls

Smart synchronization drives high-speed embroidery without manual intervention, transforming industrial sewing technology into true automated sewing.

Energy Consumption and Uptime Targets

Efficiency-driven operators focus on two key metrics: energy draw and uptime. Leading commercial embroidery machines operate at 1.2–2.5 kWh during peak high-speed embroidery, while standby modes significantly reduce overnight consumption by 50–70%. Power management systems, utilizing variable frequency drives, further minimize energy spikes by 5–12%.

Uptime optimization is another critical area, with reliability exceeding 99.8%. Automated thread break detection alone reduces stoppages by 10–25%. Thermal control systems maintain motor temperatures below 70°C, extending equipment life and enabling maintenance scheduling every 1,000–2,000 hours.

| Metric | Standard Range | Top-Tier |

|---|---|---|

| Peak energy (kWh/hr) | 1.2–2.5 | 0.8–1.4 |

| Uptime guarantee | 98.0–99.5% | 99.8–99.95% |

| MTBF (hours) | 8,000–12,000 | 15,000–18,000 |

| Operating temp (°C) | 60–70 | 55–65 |

| Service interval (hrs) | 1,000–2,000 | 1,500–2,500 |

How to Choose The Best Commercial Embroidery Machine

Selecting the right commercial embroidery machine isn’t just about finding the fastest or most feature-packed model—it’s about matching the equipment to your specific operational requirements and growth trajectory. You’ll need to evaluate production capacity, financial constraints, brand reliability, and the support infrastructure that keeps your machine running at peak performance.

Here’s how to make a decision that prepares your business for sustained success and profitability.

Assessing Your Business Needs and Production Volume

Your embroidery business scaling hinges on matching machine capacity to actual production volume. For shops handling 1,000–2,500 stitch-hours monthly, automatic thread trimming systems slash setup time by 15–25%, directly improving operational efficiency.

High-volume production demands multi-head configurations—usually 2–6 heads—to sustain commercial embroidery equipment uptime above 95%. This capital investment must align with market analysis of seasonal peaks and your embroidery industry position.

Budget Considerations and Return on Investment

Generally, you’ll invest $25,000–$60,000 per commercial embroidery machine, so financing options can reduce upfront costs by 20–40% with 3–5 year terms.

Target an 18–36 month payback period through ROI metrics tied to utilization rate—labor savings of 15–40% and incremental revenue exceeding $1,500 per 1,000 units make cost analysis essential for embroidery business tips and investment strategies.

Comparing Trusted Brands and Models

Your brand comparison starts with proven players: Brother holds 22% of global commercial embroidery machine sales, while Tajima embroidery machines saw 15% growth in multi-needle deployments during 2024.

Ricoma embroidery machines and Melco units dominate contract shops—8,000+ Melco machines shipped in 2023–2024 alone.

Model reviews reveal embroidery quality hinges on machine reliability and cost analysis that accounts for speed, needle count, and long-term performance.

Evaluating Support, Warranty, and Training Options

Crucially, you’ll need technical assistance and customer service that keep your embroidery business running—92% of vendors offer on-site warranty support within days.

Warranty terms covering parts usually add 6–18% annually, while 75% include operator training and post-purchase support.

Reviews confirm that business equipment backed by 24/7 portals and rapid technician dispatch protects your commercial embroidery machine investment long-term.

Frequently Asked Questions (FAQs)

What is the best brand of embroidery machines?

You’ll find the strongest market share belongs to Tajima embroidery machines, commanding nearly 38% of commercial sales in

Ricoma embroidery machine and SWF embroidery machine models follow closely, delivering outstanding product reliability and cost efficiency backed by responsive customer support.

Which company is best for computer embroidery machines?

Tajima embroidery machines command the strongest industry reputation for computerized systems, backed by outstanding uptime and product innovation.

Brother holds significant market share in North America, while Happy Japan earns brand loyalty through durability and customer support.

Is commercial embroidery profitable?

Yes—commercial embroidery can be a goldmine when you streamline workflows.

Small shops average 10–20% profit margins annually, while high-volume operations push above 20% through market demand trends and cost reduction strategies in the embroidery industry.

What is the best thread for commercial embroidery machine?

You’ll want high-tenacity polyester for your embroidery machine—it delivers exceptional color fastness and stitch durability across fabric compatibility tests.

Core-spun threads reduce breakage, keeping your embroidery business running smoothly with consistent embroidery materials and custom embroidery quality.

How often should commercial embroidery machines be serviced?

You should schedule preventive care every 200–400 operating hours to maintain machine uptime and reduce repair costs. Many commercial embroidery machines require professional service intervals every 6–12 months under high-volume production conditions.

What are the average power consumption costs?

Your commercial embroidery machine’s power consumption usually runs 350–600 watts, translating to monthly electricity costs of $50–$150 for eight-hour shifts.

Servo motors deliver 20–40% energy cost savings over traditional systems, maximizing operating expenses efficiency.

Can commercial embroidery machines handle metallic threads?

Most machines excel with metallics using specialized needles and tension control—yet success demands proper thread path setup and reduced speeds.

You’ll need metallic settings with stitch optimization to prevent breakage and maintain commercial embroidery quality.

Are there eco-friendly options for commercial embroidery?

Yes—leading commercial embroidery machines now feature energy-efficient servo motors that cut consumption by 5–15%, recyclable consumables reducing waste by 25–45%, and low-VOC thread finishes adopted by 40–60% of manufacturers for greener production.

What certifications should operators have for commercial machines?

Like a pilot earning wings before takeoff, you’ll need OSHA compliance training and manufacturer-specific operator certifications.

Safety protocols and regulatory standards guarantee your team operates commercial embroidery machines properly while meeting textile industry requirements.

What materials can commercial embroidery machines stitch on?

You’ll find these machines handle woven fabrics like cotton and polyester, plus denim with proper stabilizer choices.

Leather and felt need specialized needle selection, while thread types and material thickness dictate your setup for ideal garment decoration across the textile industry.

Conclusion

The right machine acts like a master conductor—every needle, thread path, and automation feature must synchronize flawlessly to hit your production targets. When you’ve evaluated the best commercial embroidery machines reviewed here against your workflow demands, you’re not just buying equipment; you’re architecting your shop’s capacity for the next five years.

Match specifications to revenue goals, and you’ll transform capital investment into consistent profit margins that compound with every completed order.