This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your standard domestic machine just stalled out on denim for the third time this week. That telltale grinding sound means you’re pushing a 60-watt motor beyond its limits, asking it to power through materials it was never engineered to handle.

Heavy duty sewing machines solve this problem with motors delivering 100 watts or more, metal frames that absorb vibration instead of flexing under load, and feed systems that grip thick fabrics like canvas and leather without slipping. These machines don’t just survive tough materials—they’re built specifically to conquer them.

Whether you’re upholstering furniture, crafting leather goods, or sewing through twelve layers of denim, the right heavy duty machine transforms frustrating projects into smooth, professional work.

Table Of Contents

Key Takeaways

- Heavy-duty sewing machines are distinguished by motors delivering 100+ watts, metal frame construction that absorbs vibration, and feed systems that grip thick fabrics without slipping—solving the core problem of standard machines stalling on materials like denim, canvas, and leather.

- The seven reviewed machines (including Juki TL2000QI, Janome HD3000, Singer 4452, and Brother models) share critical specs like 800-1,500 stitches per minute, metal chassis construction, and adjustable presser foot pressure, with prices ranging from $230-$600 depending on features and speed capabilities.

- Professional tailors, home sewists working with thick fabrics, quilters, and small business owners benefit most from investing in heavy-duty machines, as these users regularly encounter materials that require sustained piercing power and durability beyond standard domestic models.

- Proper maintenance—including lint removal before every project, oiling moving parts every 8-12 hours of use, matching needle size (90/14 to 110/18) to fabric weight, and scheduling annual professional servicing—extends machine lifespan to 8-15+ years and maintains consistent stitch quality.

Top 7 Heavy Duty Sewing Machines Reviewed

You need a machine that won’t quit when you’re pushing through layers of denim or wrestling with thick canvas. The right heavy-duty sewing machine transforms impossible projects into manageable work, giving you the control and power to handle materials that would choke standard models.

The right heavy-duty sewing machine transforms impossible projects into manageable work, giving you control over materials that would choke standard models

Here are seven machines that deliver the strength, speed, and precision you need to master any heavy fabric challenge.

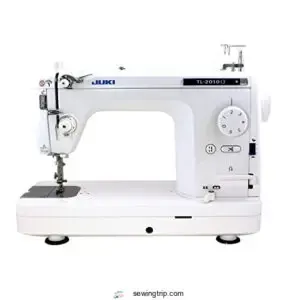

1. Juki Long Arm Sewing Machine

The Juki TL2000QI transforms your long arm quilting projects with industrial-grade precision. You’re getting aluminum construction, corded electric power, and an automatic thread cutter that manages heavy-duty threading like a dream. This longarm sewing machine excels at free-motion quilting, and it’s built for serious quilters who demand performance.

The extended throat space lets you tackle large-scale work with confidence. Just remember—sewing machine maintenance matters here. Regular oiling keeps this industrial sewing machine running smoothly, and you’ll master it with practice.

| Best For | Advanced quilters and serious sewers who need industrial-grade performance for large-scale projects and free-motion work. |

|---|---|

| Brand | JUKI |

| Material | Aluminum |

| Power Source | Corded Electric |

| Weight | Not specified |

| Needle Threader | Automatic |

| Free Arm | Yes |

| Additional Features |

|

- Extended throat space and aluminum construction handle heavy-duty fabrics and quilting with industrial precision

- Automatic thread cutter and free-motion capability streamline your workflow on complex projects

- Compatible with specialized presser feet like walking foot for versatile quilting techniques

- Steep learning curve means beginners will struggle—this machine demands practice and experience

- Regular oiling and maintenance required to keep performance consistent

- Some users report issues with bobbin winder and thread cutter reliability

2. Janome Heavy Duty Sewing Machine

When power meets precision, the Janome HD3000 delivers outstanding fabric handling through its all-metal frame and high-torque motor. You’re commanding 18 built-in stitches, a one-step buttonhole, and speeds reaching 1,000 stitches per minute.

The Janome HD1000 and HD5000 share similar heavy-duty motors with adjustable presser foot pressure for varied fabric thickness. Machine durability shines through chrome-plated needle plates and industrial-grade components.

Sure, you’ll find limited stitch patterns compared to computerized models, but this trade-off brings rock-solid reliability for denim, canvas, and leather projects.

| Best For | Sewers who need a reliable workhorse for heavy fabrics like denim, canvas, and leather without the complexity of computerized features. |

|---|---|

| Brand | Janome |

| Material | Metal frame |

| Power Source | Corded Electric |

| Weight | 21 pounds |

| Needle Threader | Built-in |

| Free Arm | Yes |

| Additional Features |

|

- All-metal frame and high-torque motor handle thick layers and tough materials with ease

- Simple, mechanical design means fewer things can break and easier troubleshooting

- Fast stitching speed up to 1,000 stitches per minute keeps projects moving

- Only 18 stitches available, which limits decorative options compared to modern machines

- No speed control feature, so you’re relying entirely on foot pedal pressure

- Short power and pedal cords can restrict where you set up your workspace

3. Juki Portable Sewing Machine

If you crave both mobility and might, the Juki TL2000QI answers with 1,500 stitches per minute in a compact storage form. This portable design houses an aluminum construction weighing just 38 pounds, delivering machine durability without anchoring you to one spot.

You’re mastering heavy fabric from denim to canvas through adjustable presser foot pressure and automatic needle threading. The knee lifter lever frees your hands for intricate control on thick fabrics.

Heavy-duty sewing machines rarely combine speed with portability this effectively, making sewing machine reviews consistently praise its balanced performance on challenging materials.

| Best For | Quilters and sewers who need a powerful machine that can handle heavy fabrics but still want the flexibility to move it between workspaces or store it away when not in use. |

|---|---|

| Brand | JUKI |

| Material | Aluminum |

| Power Source | Corded Electric |

| Weight | 38 pounds |

| Needle Threader | Automatic |

| Free Arm | No |

| Additional Features |

|

- Blazing fast 1,500 stitches per minute with automatic thread trimming saves time on large projects

- Knee lifter and automatic needle threader give you hands-free control for precision work on thick materials

- Lightweight aluminum build at 38 pounds makes it easy to transport without sacrificing durability

- No dedicated scant 1/4″ foot included, so you may need to buy one separately or adjust settings for quilting

- Built-in lighting could be brighter, and you might need an external lamp for detailed work

- Thread cutting requires firm foot pedal pressure, which some users find takes getting used to

4. Brother Heavy Duty Sewing Machine

When portability meets your need for raw stitching force, the Brother ST371HD delivers 800 stitches per minute through a metal frame engineered for stability. You’re commanding 37 stitch patterns, automatic needle threading, and adjustable presser foot pressure that overcomes denim, canvas, and faux leather without hesitation.

This heavy-duty sewing machine transforms thick fabric challenges into mastered projects, with stitch quality remaining consistent across multiple layers. The Brother machine offers outstanding value, blending speed with the rugged construction your ambitious sewing demands require.

| Best For | Sewers tackling heavy fabrics like denim, canvas, and upholstery who need a reliable machine that won’t slow down on thick layers. |

|---|---|

| Brand | Brother |

| Material | Metal |

| Power Source | Corded Electric |

| Weight | 18.4 pounds |

| Needle Threader | Automatic |

| Free Arm | Yes |

| Additional Features |

|

- Powerful motor handles multiple layers of thick fabric at 800 stitches per minute without skipping stitches

- Metal frame construction provides stability and durability for long-term heavy-duty use

- 37 built-in stitches with automatic needle threader and adjustable presser foot pressure make it versatile for different projects

- Bobbins aren’t compatible with other Brother machines, so you’ll need to keep ST371HD-specific bobbins on hand

- Some users report the foot pedal cord could be longer and occasional burning plastic smell during extended use

- Customer support can be difficult to reach when you need help troubleshooting issues

5. Heavy Duty Sewing Machine

When you’re commanding 110 stitch applications and a motor engineered for piercing thick fabrics, you’re holding the Singer 4452 that transforms denim and canvas into mastered projects.

This heavy-duty sewing machine features a full metal frame for rock-solid machine durability, with sewing speed reaching 1,100 stitches per minute. You’ll handle multiple fabric thickness layers with confidence, thanks to enhanced motor power and a built-in needle threader.

The best heavy-duty sewing machine for your arsenal delivers industrial-grade user experience at $229.99, bridging the gap between home and industrial vs heavy-duty sewing machines.

| Best For | Sewers who regularly tackle heavy fabrics like denim, canvas, and leather, or who need to stitch through multiple layers quickly and reliably. |

|---|---|

| Brand | SINGER |

| Material | Metal/Plastic |

| Power Source | Corded Electric |

| Weight | 14.6 pounds |

| Needle Threader | Built-in |

| Free Arm | No |

| Additional Features |

|

- Powerful motor handles thick materials and multiple layers without bogging down, reaching speeds up to 1,100 stitches per minute

- Full metal frame provides exceptional stability and durability for long-term use on demanding projects

- 110 stitch applications give you plenty of versatility for garment construction, quilting, and home decor projects

- Mechanical design requires regular cleaning and oiling after each project to maintain peak performance

- Upright spool pin can cause thread to jump and wrap around the pin, leading to occasional jams

- At 14.6 pounds, it’s on the heavier side, which may make it less convenient to move or transport

6. Brother High Speed Sewing Machine

When you’re tackling canvas or denim, Brother’s high-speed machines deliver 1,500 to 2,500 stitches per minute without sacrificing stitch quality. The Brother PQ1500SL, Brother ST371HD, and Brother ST150HDH feature sturdy metal chassis construction for machine durability during demanding projects.

You’ll appreciate the precision pin feeding system and automatic thread trimmer that boost sewing efficiency. These models handle heavy fabric layers at impressive speeds, making them ideal for quilters and upholsterers.

With high-speed stitching capabilities and industrial-grade speed performance, Brother transforms thick materials into finished projects faster than standard machines.

| Best For | Experienced sewers and quilters who need to power through thick fabrics like denim, canvas, and weighted blankets at professional speeds. |

|---|---|

| Brand | Janome |

| Material | Aluminum/Plastic |

| Power Source | Corded Electric |

| Weight | 20 pounds |

| Needle Threader | Manual |

| Free Arm | No |

| Additional Features |

|

- Blazing fast speeds up to 1,500 stitches per minute with automatic thread trimmer and advanced needle threader that cut down setup time between projects

- Built tough with a metal chassis and precision pin feeding system that handles multiple layers of heavy fabric without skipping stitches

- Comes loaded with useful accessories including a wide table, 7 specialty feet, and knee-lifter for tackling large quilting and upholstery projects

- Not beginner-friendly—the speed and features can be overwhelming if you’re just starting out

- The needle threader can be tricky to work with, and the side-loading bobbin won’t alert you when thread runs low

- Some users report the machine gets squeaky with heavy use, and the pin feed mechanism may fail over time

7. Singer Heavy Duty Sewing Machine

You’ll master thick fabrics with Singer’s Heavy Duty 4452, 4432, and 4411 models that push 1,100 stitches per minute. These Singer heavy duty sewing machines feature all-metal frame construction that eliminates vibration when you’re sewing multiple denim layers.

The Singer Heavy Duty 4411 delivers excellent stitch quality on canvas and leather, while the 4452 adds 32 built-in stitches for versatility.

With adjustable presser foot pressure and a powerful motor rated above 60 watts, your Singer machine transforms challenging materials into professional results. That metal frame means these heavy duty sewing machines maintain precision even during marathon sewing sessions.

| Best For | Sewers tackling heavy-duty projects like denim, canvas, upholstery, and leather who need speed and power without spending a fortune. |

|---|---|

| Brand | Brother |

| Material | Metal |

| Power Source | Corded Electric |

| Weight | 29.8 pounds |

| Needle Threader | Automatic |

| Free Arm | No |

| Additional Features |

|

- Metal frame construction keeps the machine stable even at 1,100 stitches per minute, so you get clean stitches on thick fabrics without vibration or skipped stitches.

- Adjustable presser foot pressure and a motor over 60 watts let you switch between delicate cottons and dense multi-layer projects without fighting the fabric.

- Easy threading features like the built-in needle threader and top drop-in bobbin with clear cover save time and frustration, especially for beginners.

- Some users report the internal gears can dry out and get gummy over time, requiring regular cleaning and oiling to keep performance consistent.

- The machine may not include a printed manual in the box, so you’ll need to download instructions separately or use the Creativate app.

- Quality needles matter—cheap needles don’t work well, so you’ll want to stick with Singer-branded needles for best results.

Key Features of Heavy Duty Sewing Machines

You need a machine that won’t quit when you’re pushing leather, canvas, or multiple layers of denim through the feed dogs. Heavy duty sewing machines earn that title through specific engineering choices, not just marketing hype.

Let’s break down the four core features that separate true workhorses from machines that just look tough.

Powerful Motors for Thick Fabrics

You need serious torque output to conquer denim, canvas, and leather without your machine choking mid-seam. Powerful motors rated between 1.0 and 1.5 horsepower deliver the fabric penetration you demand, pushing needles through multiple layers with authority.

Here’s what transforms sewing performance on thick fabrics:

- Motor efficiency sustains 1,000-1,300 stitches per minute without overheating

- Servo configurations give you precision speed control at low speeds

- High-torque design prevents needle stalling on dense materials

- Direct-drive systems improve starting accuracy on heavy-duty sewing machines.

To guarantee clarity in your sewing guide, consider using clear science writing techniques.

Durable Metal Construction

You’ll recognize premium heavy-duty sewing machines by their steel alloys and metal frames—your foundation for conquering industrial sewing challenges.

Metal frame construction delivers vibration reduction and torque tolerance that plastic components simply can’t match. Manufacturers subject these frames to rigorous durability tests, ensuring your machine withstands years of punishing work on canvas, denim, and leather without flexing or warping under pressure.

The durability of these machines is backed by extensive research findings that highlight their ability to perform consistently.

Advanced Stitch and Speed Options

Variable speed control transforms how you handle thick layers, giving you pinpoint accuracy when starting seams. Sophisticated sewing machine features put professional precision at your fingertips:

- Adjustable stitch length and width refine topstitching on dense fabrics like canvas and denim

- Dual feed mechanisms eliminate skipped stitches during high-pressure seams

- Presser foot pressure adjustment prevents puckering on heavy materials

- Programmable backstitch options reinforce seam ends automatically for bulletproof construction

Specialized Presser Feet and Accessories

Interchangeable feet release your machine’s full potential. Walking feet feed vinyl and thick layers evenly without slippage, while zipper feet nail precise installations on leather goods. Teflon or roller presser feet glide across sticky vinyl-coated fabrics, eliminating frustration.

You’ll also appreciate edge guides for consistent seam allowances and the automatic needle threader that saves time. The free arm option simplifies cuffs and sleeves—essential sewing machine accessories and parts for serious fabric handling.

Benefits of Using Heavy Duty Sewing Machines

You’ve seen the features that make these machines built to last, but raw power is just the beginning. The real revolution is what heavy-duty machines release for your sewing projects—from tackling upholstery that would jam a regular machine to finishing professional-grade work in half the time.

Here’s how investing in a heavy-duty model transforms your capabilities and puts you in complete control of any fabric that comes your way.

Enhanced Performance on Heavy Materials

Heavy materials demand machines engineered for relentless fabric penetration and motor efficiency. With heavy-duty sewing machines, you’ll conquer canvas, leather, and denim like never before.

- 60–80% more needle penetration force slices through multiple thick layers effortlessly

- High-torque motors maintain stitch consistency even under extreme load

- Titanium-coated needles boost needle durability, cutting skipped stitches by 25%

- Enhanced material handling prevents slippage on dense textiles

- Stable speeds deliver professional results on demanding leather sewing machine projects

Long-lasting Durability and Reliability

Your investment in a heavy-duty machine buys years of relentless performance. Metal frame construction slashes vibration, while industrial-grade motors deliver 1,000+ hours between servicing.

Quality gear trains reduce friction and heat—key for motor longevity. Component durability matters: look for warranty coverage on structural elements and assemblies.

That’s the difference between disposable consumer models and machines engineered for mastery.

Efficient Sewing of Multiple Layers

That durability translates directly into multi-layer mastery. Heavy-duty sewing machines excel at layered fabric handling, powering through six-plus layers of denim without protest.

Strong feed dogs and walking feet prevent shifting during dense material sewing, while high-torque motors maintain piercing power. You’ll conquer bulk seam management with precision:

- Dual-feed systems eliminate layer bunching

- Adjustable presser foot pressure controls thick stacks

- Large throat space accommodates bulky accumulation

- Ballpoint needles minimize skipped stitches

- Consistent tension prevents seam puckering across layers

Versatility for Various Projects

True versatility means you can tackle upholstery one day, leather the next. Heavy duty sewing machines handle fabric variety from canvas to silk with adjustable presser feet and stitch options for every material.

Project scaling becomes seamless with accessory compatibility—walking feet for quilting sewing machine work, roller feet for vinyl. That’s mastery across heavy duty applications without switching equipment.

How to Choose The Right Model

Choosing the right heavy duty sewing machine isn’t about picking the most expensive model, it’s about matching the machine’s capabilities to your specific needs. You need to think about what fabrics you’ll work with most, how many stitch options matter for your projects, and whether your skill level requires simpler controls or sophisticated features.

Let’s break down the four key factors that’ll help you make a confident decision.

Assessing Project and Fabric Needs

Before you commit to any heavy-duty sewing machine, map out your fabric battlefield. Your material selection drives every spec—from fabric thickness and thread choice to the sewing speed you’ll actually need.

- Match your machine’s capacity to the maximum fabric thickness you’ll tackle, whether that’s denim, upholstery, or canvas

- Count the layers you’ll sew regularly to determine required pressure and stitch length control

- Consider how frequently you’ll switch between heavy and lightweight materials for workflow efficiency

Comparing Stitch Options and Speed

Speed controls separate workhorse machines from weekend warriors. You’ll want 1,100+ stitches per minute for canvas and leather, but adjustable throttle matters more than raw speed.

Triple-stitch reinforcement and differential feed systems prevent skipped stitches on thick layers, while programmable tension keeps stitch quality consistent.

Check user reviews for real-world performance on your target materials—specs alone don’t reveal how motor power translates to penetration force.

Considering User Experience and Skill Level

Your learning curve matters just as much as machine specs. User feedback consistently shows that user-friendly interfaces and guided stitch programs accelerate skill building, while ergonomic design reduces fatigue during extended sessions.

If you’re new to heavy-duty sewing machines, prioritize models with clear user interfaces and accessible troubleshooting features—these details transform challenging fabrics into conquerable territory for both beginners and experienced sewists.

Evaluating Budget and Warranty Coverage

Your investment deserves protection, so budget planning must account for both upfront cost and long-term coverage options. Price comparison reveals clear tiers in heavy-duty sewing machines:

- Entry models ($200–$350) deliver solid basics with 1–2 year warranties

- Mid-tier units ($350–$600) balance features with 2–3 year protection

- Premium choices ($600–$1000) offer extensive coverage (3–5 years) and sophisticated capabilities

Smart cost analysis includes warranty terms—they’re your safety net.

Maintenance Tips for Heavy Duty Machines

Your heavy duty machine is an investment that demands respect and care. Without proper maintenance, even the most powerful motor and metal frame will lose their edge.

Here’s how to keep your machine running at peak performance for years to come.

Regular Cleaning and Oiling Practices

Your heavy duty machine thrives on consistent care—think of it as feeding power back into your workhorse. Remove lint from feed dogs and bobbin areas before every project, then apply manufacturer-recommended oil to pivots and moving joints every 8–12 hours of use. Wipe away excess to prevent fabric staining, and keep a maintenance log tracking dates and parts serviced for peak performance.

Using Correct Needles and Threads

Match your needle types and thread selection to fabric weight, and you’ll achieve perfect seams every time. Heavy-duty sewing machines demand universal or denim needles sized 90/14 to 110/18 for thick materials, paired with polyester or bonded nylon thread built for high tensile strength.

Fabric compatibility drives your choices—test on scraps first, checking tension control before committing. Wrong pairings shred seams and skip stitches, robbing you of precision.

- Select sharp needles (universal or ballpoint) designed specifically for multi-layer fabrics to prevent breakage during heavy-duty projects.

- Choose thread rated for industrial use with reinforced polyester or bonded nylon construction that withstands stress on dense materials.

- Align needle size to fabric content—heavier denim or canvas requires 100/16 or 110/18 needles, lighter upholstery needs 90/14 sizing.

Tension and Stitch Adjustment Advice

Perfect thread tension transforms every seam into a power move—balanced stitches lock precisely at the fabric midline, eliminating puckering and loops. Start with manufacturer settings, then fine-tune in quarter-turn increments while testing on scraps.

Adjust stitch balance for thick layers by increasing stitch length and easing presser foot pressure. Your needle selection and sewing speed directly impact tension stability, so dial in fabric stretch tolerance before committing to final runs.

Scheduling Professional Servicing

Beyond tension tweaks and home care, your machine demands expert eyes—schedule professional servicing every 12 months to release peak performance. Certified technicians inspect timing, motor health, and hidden wear patterns you can’t catch alone.

- Book service visits during off-peak hours to minimize production downtime and keep your workflow unstoppable.

- Verify technician qualifications through manufacturer authorization—amateurs void warranties and miss critical issues.

- Request detailed maintenance schedules customized to your fabric types and daily stitch counts.

- Explore service contracts that bundle inspections, parts, and warranty extensions into predictable servicing costs.

- Document every repair to track machine health and justify future upgrades with hard data.

Who Should Invest in Heavy Duty Machines

Not every sewing project needs a heavy-duty machine, but certain types of work absolutely demand that extra power and durability. If you’re pushing standard machines to their limits or constantly dealing with thick materials, you’re probably ready to upgrade.

Let’s look at who benefits most from investing in these industrial-strength workhorses.

Professional Tailors and Seamstresses

Your reputation depends on seam precision and consistent results across varied fabric selection, deadline after deadline. Heavy-duty sewing machines deliver the reliability you need for professional sewing, handling challenging tailoring techniques with powerful motors and industrial-grade durability.

When client management demands efficiency, workflow optimization starts with equipment that won’t fail mid-project, making commercial sewing machines essential for sustainable business growth.

Home Sewists Working With Thick Fabrics

You don’t need industrial machinery to master denim hems or upholstery repairs at home. A heavy-duty sewing machine for thick fabrics transforms your fabric selection and sewing techniques, delivering professional stitch quality on canvas, leather, and multiple layers.

Thread choices matter less when your machine upgrades include 1.0+ amp motors and metal frames, giving you control over challenging materials without frustration or skipped stitches.

Quilters and Craft Enthusiasts

Quilting mastery starts with feed dogs strong enough to grip your batting options and fabric selection without shifting mid-seam. You’ll command precision on thick quilting sandwiches when your heavy duty sewing machine for thick fabrics features a wide throat space, automatic thread trimming, and built-in utility stitches that accelerate your quilting techniques.

Strong traction transforms multi-layer projects into efficient piecing work.

Small Business and Commercial Users

Production speed separates profit from loss when you’re running commercial sewing operations. Heavy duty motors in industrial sewing machines reduce your fabrication time by 20–30% on thick layers, while metal frames withstand 8–12 hour duty cycles daily.

Professional embroidery and industrial fabric handling demand servo motor precision, lower thread breakage, and warranty coverage that protects your business efficiency investment long-term.

Frequently Asked Questions (FAQs)

What is the best heavy duty sewing machine?

The Juki DDL-8700 stands out with its industrial-grade metal frame, 5,500 SPM motor performance, and outstanding jam resistance through 12 denim layers—making it the benchmark in heavy duty sewing machines.

Should you buy a heavy-duty sewing machine?

If you wrestle with denim or leather regularly, absolutely. Heavy duty sewing machines cut through thick materials with fewer headaches, but casual sewists working lightweight fabrics won’t justify the investment.

What is a heavy-duty sewing machine?

A heavy-duty sewing machine delivers exceptional motor power and machine durability to tackle heavy fabric and extreme fabric thickness.

These HeavyDuty Sewing Machines feature reinforced metal frames, enhanced piercing force, and specialized heavy duty sewing machine features for demanding sewing techniques.

Which sewing machine is right for You?

Measure twice, cut once—the same goes for choosing your sewing machine. Match your sewing needs and fabric types to motor power, frame durability, and stitch options.

Check user reviews, compare brands, then set your sewing budget wisely.

What is the weight of typical heavy-duty machines?

Typical domestic models range from 12 to 15 pounds for portability, while professional units with enhanced motor power and metal construction hit 25 to 40 pounds, ensuring outstanding sewing capacity on thick materials.

Are heavy-duty sewing machines noisy during operation?

Yes, you’ll encounter motor hum and vibration—sound levels usually range from 60 to 85 decibels during operation.

Metal frames with vibration control offer better noise reduction and operational silence than budget plastic models.

Can these machines handle intricate decorative stitches?

Most modern heavy-duty sewing machines handle decorative patterns beautifully, offering 60 to 100 built-in stitches with precise tension control.

Quality models maintain consistent stitch complexity across multiple fabric layers, perfect for embellishment techniques.

What accessories are essential for heavy-duty sewing machines?

You’ll need specialized presser feet, heavy-duty needles, quality machine oil, extra bobbin cases, and high-capacity bobbins.

Thread management tools like automatic needle threader and built-in thread cutter simplify complex projects on thick materials.

Can heavy duty machines sew leather effectively?

A cobbler switching from hand-stitching to machine work discovers leather stitching transforms with heavy-duty motors.

These machines handle sewing thick leather up to 3 mm effectively when you pair piercing power with proper leather needle selection and machine durability.

Whats the average lifespan of these machines?

With proper maintenance, you can expect 8 to 12 years of reliable heavy duty performance from mid-range models, while industrial-grade equipment reliability often exceeds 15 years through consistent sewing machine maintenance and care.

Conclusion

Think of your sewing machine as the foundation of every project—weak foundations crumble under pressure, while solid ones support your ambitions without hesitation.

Now you’ve got the specs, features, and real-world insights to select the best heavy duty sewing machine reviewed for your exact needs.

Stop wrestling with inadequate equipment. Invest in a machine that matches your skill and material demands, then watch your most challenging projects transform into your proudest accomplishments.

- https://en.wikipedia.org/wiki/Sewing_machine

- https://www.singer.com/collections/singer%C2%AE-portable-sewing-machines?srsltid=AfmBOoqo_sJb7jJjZi5onqzeDJlg3WIavNFdikrZOvIeASfa4f6o1ruF

- https://academichelpexpress.blog/2024/08/please-use-the-bulleted-points-and-the-rubric-below-to-guide-your-work-your-pa/

- https://x.com/godofprompt/status/1990526288063324577

- https://www.linkedin.com/posts/bohdanlukianets_tasks-study-research-activity-7373377539521667072-UTEi