This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A lockstitch machine capable of 6,000 stitches per minute doesn’t just sew faster—it transforms what’s possible in a production environment. While home machines tap out around 1,100 stitches per minute and require frequent breaks, industrial equipment runs continuously for hours, powering through leather, canvas, and multi-layered assemblies without breaking stride.

That endurance comes from all-metal construction, servo motors that slash energy costs by 70%, and automatic lubrication systems that keep components moving smoothly shift after shift.

Whether you’re scaling up an apparel operation, outfitting an upholstery shop, or tackling heavy-duty repairs, the right industrial machine becomes the workhorse that defines your capacity and quality standards.

Table Of Contents

- Key Takeaways

- What Sets Industrial Sewing Machines Apart

- Types of Industrial Sewing Machines

- Key Features to Look For

- Comparing Industrial Sewing Machine Applications

- Top 9 Best Industrial Sewing Machines

- 1. VEVOR Industrial Lockstitch Sewing Machine

- 2. Singer Heavy Duty Sewing Machine

- 3. Juki DDL-8700 Industrial Sewing Machine

- 4. Juki Lockstitch Industrial Sewing Machine Combo

- 5. Juki Heavy Duty Sewing Machine

- 6. Leather Sewing Machine Heavy Duty Industrial

- 7. Heavy Duty Industrial Sewing Machine

- 8. Servo Motor for Sewing Machine

- 9. Industrial Sewing Machine Servo Motor Kit

- Essential Maintenance and Setup Tips

- Choosing The Right Machine for Your Needs

- Leading Brands and Popular Models

- Innovations and Market Trends in Industrial Sewing

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Industrial sewing machines deliver 2,000–6,000 stitches per minute with all-metal construction and servo motors that cut energy costs by 60-80%, transforming production capacity beyond what home machines can handle.

- The Juki DDL-8700 consistently ranks as the top industrial choice for 2025, hitting 5,500 stitches per minute with cast-iron durability and automatic lubrication that extends machine life to 15+ years under heavy use.

- Servo motors have become the smart investment over clutch motors, offering precise speed control from 200-4,000+ RPM, running 30 decibels quieter, and eliminating the constant power draw that makes clutch motors expensive to operate.

- Matching your machine to specific materials and volume is critical—walking foot mechanisms for leather and thick fabrics, programmable patterns for furniture production, and presser foot lifts exceeding 10mm for marine canvas work define successful equipment selection.

What Sets Industrial Sewing Machines Apart

Industrial sewing machines aren’t just bigger versions of home models—they’re built from the ground up for a completely different level of performance. You’ll notice the difference the moment you fire one up, from the raw power to the precision stitching that holds up under real production demands.

Let’s break down what makes these machines worth the investment and why they dominate professional workrooms.

Speed and Power Capabilities

Speed separates contenders from champions in industrial sewing. You’ll find machines delivering 2,000–6,000 stitches per minute, with high-end models pushing beyond that threshold. Motor horsepower reaches up to 1 HP (750 watts), paired with 8.6 Nm torque output for dense materials.

Servo motors offer speed customization from 50–3,000 RPM while achieving 80% energy savings—power output that’s suitable for your production demands without the waste. This growth is partly fueled by automation in textiles.

Durability and All-Metal Construction

All-metal construction elevates durability beyond what you’d expect from home equipment. Frame rigidity improves by 300%, while gear lifespan extends 3–5 times longer than plastic equivalents. Heavy-duty sewing machines with metal internals cut repair costs by $100–$200 annually and retain 40% resale value after a decade.

This is because, unlike metal gears, plastic gears wear down with use.

Warranty length generally reaches 12 months on metal chassis—reflecting manufacturer confidence in industrial sewing machine features built to last 30+ years.

Continuous Operation and Motor Types

Your machine’s motor determines whether you can run multi-shift operations without overheating. Servo motors cut energy consumption by 70% versus clutch motors, which draw power continuously and generate excess motor heat. That heat causes thread degradation—up to 72% loss in breaking strength at 4,700 rpm.

Servo motors slash energy use by 70% and prevent the overheating that destroys thread strength in multi-shift operations

Servo units also improve automation stability and reduce operator impact through precise speed control, making them the smarter investment for continuous production.

Professional-Grade Stitch Quality

When you’re paying for professional-grade sewing machine performance, stitch consistency matters most. Industrial models maintain above 98% consistency in mass production, with defect rates under 0.2% per 10,000 seams.

You’ll see seam strength retention above 92% after laundering, while precise thread tension control keeps looping defects below 1 in 5,000 stitches—reliability your heavy-duty projects demand.

Types of Industrial Sewing Machines

Not all industrial sewing machines are built for the same job. Each type specializes in specific stitching techniques and material handling, from basic lockstitch work to complex edge finishing.

Here’s what you need to know about the four main categories that’ll shape your purchasing decision.

Straight-Stitch Machines

You’ll find straight-stitch machines deliver unparalleled seam quality and speed control for high-volume production. Single-needle lockstitch machines like the Juki DDL8700 Complete dominate commercial settings, running at speeds up to 5,500 stitches per minute.

These industrial sewing machines excel at fabric handling through precise thread tension and needle types optimized for consistent straight seams—exactly what you need when quality can’t be compromised.

Zigzag and Multi-Function Machines

When your work demands stitch versatility beyond straight seams, commercial zigzag machines deliver reinforcement applications for stretch garments and sportswear at 3,000–5,000 stitches per minute.

Programmable machines with digital patterns cut equipment changeover time to under 60 seconds—that’s a 25–35% time reduction compared to single-function setups. Multi-function machines adapt instantly to your changing production needs without swapping heads.

Heavy-Duty and Leather Machines

Servo motor integration powers today’s industrial sewing machines for leather through materials up to 5/16″ thick, delivering 18% higher productivity while cutting energy use by 12%.

You’ll handle leather thickness variations with automated thread tension controls—now standard in 65% of new heavy-duty models.

Specialized needle types and precise stitch penetration keep your upholstery and automotive work commanding premium rates as this segment expands at 4.6% annually.

Overlock and Serger Machines

Overlock machines dominated 45% of the industrial serger market in 2024, finishing edges at speeds your straight-stitch setup can’t match. Thread tension controls and knife adjustment options let you switch between rolled hem finishes and heavy-duty seam reinforcement without retooling.

- Four-thread serger stitch types captured 38% of market revenue, balancing strength with versatility across garment categories

- Differential feed systems prevent fabric puckering on stretch materials, critical for sportswear and technical textiles

- Coverstitch machines with automatic threading cut changeover time to under 60 seconds, boosting production flexibility

Key Features to Look For

Not all industrial sewing machines are built the same, and the difference between a smart investment and a costly mistake often comes down to a few critical features. Understanding what to prioritize—from motor types to feed systems—will help you match the machine to your specific workload and materials.

Let’s break down the five features that separate professional-grade equipment from machines that won’t hold up under real-world demands.

Motor Options: Servo Vs. Clutch

Your choice between servo and clutch motors fundamentally shapes your machine’s performance and operating costs. Clutch motors run continuously, consuming power even when idle, while servo motors draw energy only during operation—delivering 60-80% lower energy consumption. You’ll notice servo motors offer variable speed control from 200 to over 4,000 stitches per minute, whereas clutch motors run at constant maximum speeds requiring skillful feathering for precision work.

| Feature | Servo Motor | Clutch Motor |

|---|---|---|

| Energy Consumption | 60-80% less power | Runs continuously |

| Speed Control | Variable (200-4,000+ SPM) | Constant maximum speed |

| Noise Levels | 30 decibels quieter | Louder operation |

| Maintenance Needs | Less frequent servicing | Requires consistent maintenance |

| Market Adoption | Growing at 3.7% CAGR | Traditional standard |

The servo motor vs. clutch motor decision also impacts your workspace environment. Servo motors operate up to 30 decibels quieter with minimal vibration, reducing operator fatigue during long production runs. Market adoption strongly favors servo technologies, particularly in Asia-Pacific manufacturing hubs, driven by energy savings and ergonomic improvements.

Maintenance needs differ markedly: servo motors generate less heat and wear, requiring less frequent servicing compared to continuously running clutch motors, which are prone to overheating. Understanding these sewing machine motor types and their pros and cons helps you select equipment that matches your production demands and budget constraints.

Walking Foot and Even Feed Systems

Walking foot mechanisms give you precision fabric feeding that standard presser systems can’t match, especially when layering thick materials. These even-feed systems synchronize top and bottom feed, eliminating slippage on heavy-duty projects and maintaining production efficiency across varied textiles.

Technology developments now include programmable feed settings and adjustable ratios for rapid project switching.

- Fabric feed precision: Synchronized walking foot action reduces puckering by up to 30% on multilayer assemblies

- Layering performance: Higher lift capacity accommodates abrupt thickness transitions in upholstery and canvas work

- Application advantages: Essential for leather goods, automotive interiors, and marine fabrication where uniform seams matter

Thread and Needle Compatibility

Matching your thread sizing and needle types correctly prevents up to 30% of seam defects. For Tex 69 thread, you’ll want size 110 needles—that pairing delivers peak stitch quality across medium-weight fabrics.

Material matching matters: polyester and nylon threads dominate commercial work because they handle stress without snapping.

Understanding failure causes like heat buildup and misalignment keeps your production line moving, while smart usage patterns help you stock the right needle sizes for varied projects.

Stitch Length and Width Adjustments

Your industrial sewing machine should offer stitch length from 0.0 mm to 5.0 mm, with standard construction seams working best at 2.5–3.0 mm. Adjustable stitch width on zigzag-capable models generally ranges up to 5 mm.

Mechanical dials give you hands-on control, while digital enhancements on computerized models provide stitch accuracy within 0.2 mm.

Calibration needs increase with heavy use, but proper adjustment mechanisms guarantee consistent fabric impact across every project.

Safety Features and User Controls

Needle guards on your industrial sewing machine meet OSHA standards, preventing contact with moving parts. Emergency stops and automatic power-off features kick in after set intervals, while lockout procedures protect you during maintenance.

Ergonomic design reduces strain during long sessions.

Essential safety features like digital motor control and training protocols aren’t optional—they’re your first line of defense against workplace injuries.

Comparing Industrial Sewing Machine Applications

Industrial sewing machines aren’t one-size-fits-all—different industries demand different capabilities from their equipment. The machine that excels at stitching boat covers won’t necessarily be your best choice for automotive upholstery or furniture production.

Let’s look at how these machines perform across four major applications so you can match the right equipment to your specific work.

Upholstery and Furniture Production

Upholstery and furniture production demand industrial sewing machines that can handle thick, multi-layered materials without breaking stride. You’ll need equipment engineered for heavy fabrics like leather, vinyl, and foam-backed textiles—materials that would stall most home machines instantly.

- Walking foot mechanisms prevent slippage when sewing layered upholstery fabrics

- Programmable patterns enable 60% faster completion of repetitive furniture tasks

- Stitch quality consistency reduces defect rates by 17% in commercial production

- Servo motors cut energy costs by 70% while maintaining precision

Modern automation benefits include real-time monitoring and adjustable presser foot lift for diverse fabric thicknesses, making customization options practically limitless in this industrial sewing machine buying guide.

Marine Canvas and Outdoor Fabrics

Marine canvas and outdoor materials test your heavy-duty sewing machine like nothing else. You’ll need walking foot technology and a presser foot lift exceeding 10 mm to handle multi-layer assemblies of solution-dyed acrylic and PVC.

Proper fabric selection and marine stitching techniques deliver water repellency above 500 mm hydrostatic head, while stitch lengths reaching 6 mm enable canvas repair on biminis, boat covers, and weather-resistant enclosures.

Automotive Interiors and Custom Work

Custom interiors in high-end vehicles demand precision you won’t find in basic equipment. Your industrial sewing machine for upholstery needs walking foot systems and servo motors hitting 4,500 stitches per minute to handle leather stitching on car seat manufacturing projects.

Vehicle upholstery work—especially automotive upholstery with quad-stitch seams—requires commercial heavy-duty sewing machines supporting thick threads and presser foot lifts exceeding 13mm for multi-layer assemblies.

Heavy-Duty Repairs and Manufacturing

Leather goods restoration and canvas tent repairs push your professional heavy-duty sewing machine capabilities to their limits. Industrial-scale production demands equipment handling heavy-duty materials at 800-1,200 stitches per minute while maintaining manufacturing efficiency through continuous operation.

Your repair service optimization depends on these heavy fabric handling essentials:

- Industrial sewing machine motors rated 100-150 watts for consistent torque

- Presser foot lifts accommodating 8mm+ fabric thickness variations

- Commercial heavy duty sewing machine frames withstanding decades of use

- Variable speed controls reducing operator fatigue during extended sessions

- All-metal construction minimizing downtime in high-volume repair environments

Top 9 Best Industrial Sewing Machines

Now that you understand what industrial sewing machines can do and where they excel, it’s time to look at specific models that deliver on those promises.

The following nine machines represent the best options across different price points, applications, and performance levels. Each one brings something different to the table, whether you’re tackling leather upholstery, high-speed garment production, or heavy canvas work.

1. VEVOR Industrial Lockstitch Sewing Machine

The VEVOR Industrial Lockstitch Sewing Machine delivers serious power through its 550W servo motor, reaching 5000 stitches per minute while slashing energy use by 60%. You’ll punch through 15 layers of denim without breaking a sweat, thanks to lockstitch technology that guarantees professional heavy-duty stitching every time. Its LCD touchscreen gives you precision control over speed and needle positioning.

When comparing this industrial sewing machine to competitors, VEVOR’s sewing motor efficiency and industrial fabric handling capabilities stand out, especially considering its ability to tackle leather, canvas, and automotive materials with equal confidence.

Best For: Professional sewers and manufacturers working with heavy-duty materials like leather, denim, and upholstery who need high-speed production and precise control.

- Powerful 550W servo motor handles up to 15 layers of denim at 5000 stitches per minute while cutting energy use by 60% compared to traditional motors.

- LCD touchscreen gives you real-time control over speed, needle position, and stitch length with automatic features that make complex projects easier.

- Built tough with a solid metal frame and automatic oil lubrication system that keeps running through heavy industrial workloads without breaking down.

- Some users report confusing assembly instructions and quality control issues that require professional repair.

- The presser foot lift is manual, not automatic as advertised, which slows down workflow on big projects.

- At 72 pounds, it’s a beast to move around, and early buyers have experienced thread tension and stitching problems.

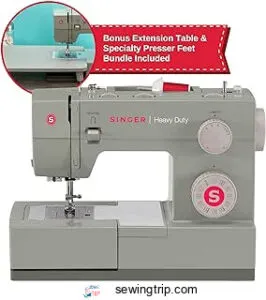

2. Singer Heavy Duty Sewing Machine

The SINGER Heavy Duty 4452 bridges the gap between home and industrial sewing machine capabilities, delivering 1,100 stitches per minute—nearly double standard household speeds. Its 60% stronger motor confidently handles denim, canvas, and upholstery, tackling thick layers that most home machines can’t manage.

While it excels with material compatibility, durability concerns arise with continuous heavy use. User ratings average 4.2 stars across 800+ reviews, highlighting its 32 built-in stitches and one-step buttonhole functionality.

Key innovations include automatic needle threading and adjustable presser foot pressure, making it one of the best industrial sewing machines for 2025 for budget-conscious sewers.

Best For: Sewers who need a reliable machine that can power through heavy fabrics like denim and canvas without the price tag of a full industrial model.

- Blazing fast at 1,100 stitches per minute, letting you finish projects in half the time compared to standard home machines.

- The 60% stronger motor tackles thick layers and tough materials that would bog down most household machines.

- Comes loaded with 32 built-in stitches and an automatic needle threader, making it versatile enough for everything from garment construction to home decor projects.

- Tension components can wear out faster than expected with continuous heavy-duty use, based on user feedback.

- Only runs at one speed, which can feel too fast for beginners working on delicate or detailed sections.

- The upright spool pin design sometimes causes thread to jump and wrap around, leading to frustrating jams mid-project.

3. Juki DDL-8700 Industrial Sewing Machine

When you need an industrial sewing machine that won’t quit, the Juki DDL8700H Heavy delivers professional heavy-duty sewing machine performance at 5,500 stitches per minute. This Juki DDL8700 features a servo motor for precise high-speed stitching and whisper-quiet operation, while its cast-iron frame durability minimizes vibration during extended runs.

You’ll achieve outstanding stitch quality on light to medium-weight materials, from cotton to denim. Market applications span apparel manufacturing, tailoring services, and design studios—backed by automatic lubrication and a 1-year warranty for reliable production.

Best For: Professional sewers, apparel manufacturers, and tailoring services who need a reliable, high-speed machine for continuous production of garments using light to medium-weight fabrics.

- Blazing fast 5,500 stitches per minute with servo motor precision means you’ll fly through production runs while keeping noise levels way down compared to old clutch motors.

- Rock-solid cast-iron frame keeps vibration minimal during long shifts, and the automatic lubrication system means less maintenance headache and longer machine life.

- Handles everything from delicate cotton to heavier denim with consistent stitch quality, plus the knee-lift presser foot goes up to 13mm for thick seam assemblies.

- Assembly is a pain—requires professional setup and customers consistently complain about confusing instructions, so budget extra time and maybe a technician.

- Limited to straight stitch only, so if you need zigzag, decorative stitches, or walking foot capability for tricky materials, you’ll need a different machine.

- Ships with potential cosmetic damage and the hefty 30kg weight means you’re committing to a permanent spot in your workspace.

4. Juki Lockstitch Industrial Sewing Machine Combo

If you want a complete workspace ready to roll, the Juki Lockstitch industrial sewing machine combo delivers everything in one package. The 48″ × 20″ table, ergonomic chair, LED lamp, and essential accessories mean you can start production immediately.

You’ll hit 5,500 stitches per minute with the included servo motor—superior motor efficiency that cuts noise and energy costs. Machine durability shines through all-metal construction, while fabric compatibility covers light to medium-weight materials with remarkable user experience and professional stitch quality.

Best For: Small business owners and serious hobbyists who want a complete, production-ready industrial sewing setup for light to medium-weight fabrics without hunting down individual components.

- Complete workspace package with table, chair, LED lamp, and all accessories included—no need to source parts separately or wait to start sewing.

- Impressive 5,500 stitches per minute with a quiet, energy-efficient servo motor that cuts down on noise and power bills compared to traditional clutch motors.

- Professional stitch quality with minimal vibration thanks to 3D-CAD engineered construction, plus compatibility with over 200 presser feet for specialized tasks.

- Assembly required and can be challenging—some users report needing professional help or dealing with unclear instructions despite video guides.

- Not suitable for heavy leather or thick materials since it’s designed for light to medium fabrics, limiting versatility for certain projects.

- Quality control issues reported by some customers, including broken parts on arrival or missing components that require dealing with customer support for replacements.

5. Juki Heavy Duty Sewing Machine

When you’re pushing through heavy duty materials like canvas or denim, the Juki Heavy Duty Sewing Machine delivers 4,000 stitches per minute without sacrificing industrial stitch quality. The all-metal construction and enhanced feed mechanism handle thick multi-layer projects where lighter models falter, making it a workhorse comparable to the Juki DDL8100 for serious production environments.

You’ll appreciate how sewing machine ergonomics meet power—the automatic lubrication system extends machine longevity factors well beyond typical industrial sewing machines, with professional heavy duty sewing machine performance averaging 15 years under constant use.

Best For: Professional sewers and small manufacturers who need a reliable workhorse for high-volume projects with heavy materials like denim, canvas, and leather.

- Blazing fast at 4,000-5,500 stitches per minute with consistent quality, even on thick multi-layer fabrics—perfect for getting through big orders quickly.

- All-metal construction and automatic lubrication system mean this machine can run for years (around 15 on average) without breaking down, making it a solid long-term investment.

- Large 11-inch arm space and adjustable stitch length up to 5mm give you the flexibility to tackle everything from quilts to automotive upholstery.

- Assembly can be a headache—some customers report missing parts, damaged tables, or needing professional help to get it running.

- No printed instructions included, so you’ll need to hunt down online videos or contact support if you run into trouble.

- Quality control seems inconsistent, with mixed reviews about motor strength and overall construction despite the brand’s solid reputation.

6. Leather Sewing Machine Heavy Duty Industrial

Specialized leather stitching demands a machine built for extreme thickness. The Leather Sewing Machine Heavy Duty Industrial manages up to 5/16″ materials with heavy-duty motors rated at 430-550 watts.

You’re looking at 3,000 stitches per minute through automotive upholstery, leather goods, and industrial fabric that would destroy conventional equipment. The cast iron frame weighs 71.5 pounds, guaranteeing machine durability and zero vibration during marathon production runs.

This heavy-duty sewing machine manages multi-layer saddle work and canvas tent repairs, where walking foot mechanisms prove essential for consistent feed.

Best For: Professional tailors, leather workers, and small businesses needing a reliable machine for heavy fabrics like leather, canvas, and upholstery.

- Durable cast iron build with low vibration for long-lasting performance.

- Fast stitching speed (up to 3,000 stitches/minute) boosts efficiency for bulk projects.

- Walking foot ensures smooth, even feeding on multi-layer or thick materials.

- Heavy and large, requiring a dedicated workspace.

- Best suited for medium-thickness to heavy materials, not ideal for very thin or extra thick fabrics.

- Requires regular maintenance and care to maintain peak performance.

7. Heavy Duty Industrial Sewing Machine

You’ll find GOSHET’s industrial sewing machine frames built for serious workshop production at $199, which makes it one of the best industrial sewing machines 2025 for budget-conscious professionals.

Heavy-duty motors drive a cast iron shell through thick material handling tasks, managing medium-weight fabrics for upholstery and alteration work.

This professional heavy-duty sewing machine features automatic oil spraying that keeps heavy-duty stitching remarkably quiet during continuous runs. The double thread rotary hook and adjustable needle controls make industrial fabric processing straightforward for beginners expanding into commercial territory.

Best For: Small alteration shops and beginners stepping into industrial upholstery work who need a reliable, budget-friendly machine that handles medium to thick fabrics without breaking the bank.

- Cast iron construction and double thread rotary hook deliver durability and high-speed performance that’ll hold up through daily commercial use.

- Automatic oil spraying keeps operation smooth and quieter than you’d expect from an industrial machine at this price point.

- At $199, you’re getting professional-grade features like adjustable needle length and lower feeding for thick materials without the typical industrial price tag.

- The lower feeding method limits you to medium and thick fabrics, so delicate or thin materials are off the table.

- You’ll need to spend time on assembly and adjustments before your first project, which isn’t exactly plug-and-play.

- Even with the automatic oiling, it’s still louder than home machines, so don’t expect library-quiet sewing sessions.

8. Servo Motor for Sewing Machine

You’ll upgrade your machine’s performance dramatically with a 600W brushless servo motor that delivers precision control from 200 to 6000 RPM.

These energy-efficient sewing machines slash power consumption by 60-80%, drawing just 1W when idle compared to clutch motors’ 250W drain.

Motor noise drops substantially with servo motor sewing machine installations, eliminating belt-driven vibration while maintaining whisper-quiet operation.

Different servo motor types offer varying torque delivery, but all provide the sewing speed flexibility you need for both delicate work and high-volume production runs.

Best For: Garment factories and professional sewers who want to cut energy costs, reduce noise, and get precise speed control for everything from delicate stitching to high-speed production work.

- Saves 60-80% on electricity bills by drawing almost no power when idle (just 1W compared to 250W for old clutch motors), making it cost-effective for shops running multiple machines.

- Extremely quiet operation with minimal vibration since there’s no clutch mechanism or belt noise, creating a much more comfortable work environment during long shifts.

- Gives you exact speed control from 200 to 6000 RPM, so you can handle thick leather at low speeds or run fast production lines without losing stitch quality.

- Installation isn’t always plug-and-play — you might need a new belt or extra mounting hardware depending on your machine, which adds time and cost.

- Some users report inconsistent power delivery and torque, especially at lower speeds, so performance can vary depending on the specific unit.

- The instructions for programming speed settings can be confusing, and build quality is hit-or-miss according to customer reviews.

9. Industrial Sewing Machine Servo Motor Kit

Complete servo motor kits transform your industrial setup with brushless technology that’s revolutionizing production floors. These packages typically include the motor controller, foot pedal, and mounting hardware—everything needed for straightforward installation.

The brushless motors in quality kits deliver reliable torque across different servo motor types, while energy savings reach 70% compared to clutch alternatives.

Installation tips usually recommend securing the controller away from oil spray and verifying voltage compatibility.

Your sewing machine servo motor upgrade pays for itself through reduced electricity costs and whisper-quiet operation that improves your workspace.

Best For: Industrial sewing operators looking to cut energy costs and noise levels while gaining precise speed control for detailed work.

- Saves up to 70% on electricity bills since the motor only runs when you’re actually sewing, unlike clutch motors that burn power constantly.

- Gives you excellent speed control from slow, precise stitching to full speed, making it easier to handle delicate or complex projects.

- Runs much quieter and cooler than traditional motors, creating a better work environment and extending your machine’s lifespan.

- Installation can be tricky for some users, especially since the controller is attached directly to the motor rather than being separate.

- You may need to fiddle with speed settings and adjustments before getting everything dialed in just right.

- Customer service issues have been reported, including problems getting refunds or support when needed.

Essential Maintenance and Setup Tips

Getting your industrial sewing machine up and running properly isn’t something you want to rush through or skip. The difference between a machine that runs smoothly for years and one that gives you constant headaches often comes down to how well you handle the initial setup and ongoing care.

Let’s walk through the critical steps you’ll need to master, from that first assembly to keeping everything running like clockwork.

Assembly and Calibration Steps

Initial assembly of your industrial sewing machine takes 10–20 minutes when you follow documented procedures. Start by securing the oil pan, attaching the machine head, and installing the needle. Thread the head using color-coded diagrams for accuracy. Next, adjust presser foot pressure within ±5% of specs and calibrate stitch length to under 0.2 mm deviation. Tension adjustments require precision gauges to verify both needle and bobbin settings. Quality checks after each step reduce defects by 27%.

Error sources during calibration—accounting for 41% of setup issues—mostly stem from stitch length and tension missteps. Data-driven improvements using sensor analytics boost equipment efficiency by 20%, catching out-of-range parameters in real time. Functional testing after calibration adds 10–15% to setup time but improves first-pass yield by 34%, making it worth every second.

| Setup Phase | Time Required | Key Action |

|---|---|---|

| Machine Head Mounting | 3–5 minutes | Secure to table, align components |

| Threading & Needle Install | 2–4 minutes | Follow color-coded paths |

| Tension & Stitch Calibration | 5–8 minutes | Use gauges, verify accuracy |

| Quality Control Check | 2–3 minutes | Test run, adjust as needed |

Regular Oiling and Cleaning

Think of oiling your industrial sewing machine like feeding an athlete—skip it and performance tanks fast. You’ll want to oil every 7 to 8 hours of use, hitting all 27 lubrication points with clear, low-viscosity mineral oils.

Daily cleaning removes lint from bobbin cases and feed dogs, cutting downtime by 40% over five years. Regular attention to motor maintenance and sewing machine components extends machine lifespan by 30% and keeps your industrial sewing machines running strong.

Troubleshooting Common Problems

Thread breakage accounts for 22% of malfunctions, with incorrect threading causing half of these issues. Skipped stitches are responsible for 17–21% of service calls, typically due to bent needles or tension problems.

Needle breakage is attributed to 53% poor installation and 41% excessive speed through thick materials. Fabric feeding problems can be reduced by 33% with clean feed dogs, while bobbin tension adjustments resolve 78% of stitch formation complaints in industrial sewing machine maintenance.

Accessory Compatibility and Upgrades

Your machine’s potential expands dramatically with the right accessories. Three distinct shank types—high, low, and slanted—determine presser foot compatibility, though adapters boost universal fit by 60%.

Digital accessories now integrate with 65% of newer industrial sewing machines, while aftermarket upgrades like specialized binders and thread compatibility kits transform standard equipment into custom setups.

Smart attachment integration and weaving accessories make professional sewing operations more efficient considerably.

Choosing The Right Machine for Your Needs

Your next industrial sewing machine isn’t just about specs and features—it’s about matching the right tool to your specific work. The perfect machine for high-volume garment production won’t necessarily serve a custom upholstery shop, and what works in a spacious factory floor mightn’t fit your studio.

Let’s break down the practical factors that’ll help you choose a machine that actually fits your operation.

Assessing Project Volume and Material Types

Your sewing goals matter more than you might think—production scale and fabric choice drive everything from motor specs to presser foot systems. Facilities that match machines to their workload see production gains of 40–60%, while mismatches lead to breakdowns and bottlenecks.

- Volume impact: Machines built for 8–24 hour shifts handle thousands of monthly units in apparel and heavy fabrics production

- Material compatibility: Heavy-duty models power through 10 denim layers or 8 mm leather goods with adjustable pressure systems

- Machine selection: Over 85% of buying decisions hinge on fabric weight, thickness, and project demands

- Maintenance needs: High-volume operations require servicing every 400–600 hours for industrial sewing machines tackling heavy-duty sewing tasks

- Market segmentation: Apparel claims 48% of industrial sewing machine applications, followed by automotive interiors at 20%

Evaluating Space and Installation Requirements

Your factory floor isn’t a blank canvas—space and setup requirements can make or break your industrial sewing machine investment. Industrial equipment demands at least 2 to 2.5 square meters per workstation, plus floor load ratings supporting 20 kN/m² for stability.

Factor in electrical supply needs (230V to 400V), ventilation for heat management, and noise control measures when planning your industrial sewing machine setup.

Proper space allocation prevents workflow bottlenecks.

Budget Considerations and Investment Value

Smart budgeting separates profitable ventures from costly mistakes. Entry-level industrial sewing machines start at $800, while premium models exceed $5,000—but initial costs tell only part of the story.

Consider these investment factors for the best industrial sewing machines 2025:

- Operating expenses include monthly depreciation ($55) and 5-8% annual maintenance

- ROI timeframe generally runs 2-4 years with 25% productivity gains

- Machine lifespan reaches 10-15 years with proper care

- Resale value retains 40-50% after five years

- Energy-efficient sewing machines cut electricity costs by 15%

Premium equipment delivers lower long-term costs and aids home-based business opportunities through reliable performance.

Leading Brands and Popular Models

When you’re ready to invest in an industrial machine, certain brands consistently rise to the top for reliability and performance. These manufacturers have earned their reputations through decades of delivering machines that hold up under demanding production conditions.

Let’s look at the standout models that professionals trust for serious work.

Juki DDL-8700 and DNU 1541

You’ll find the Juki DDL-8700 Industrial Sewing Machine hitting 5,500 stitches per minute, with its cast-iron frame reducing vibration during continuous runs. The DNU 1541 brings walking foot precision for leather and upholstery work.

Best industrial sewing machines 2025 comparisons show these models excel in fabric compatibility and maintenance needs, with user reviews praising their servo motor efficiency and automatic lubrication systems.

Brother S-7300 and Durkopp Adler 867

You’ll get 5,000 stitches per minute from the Brother S-7300A on medium-weight materials, with electronically controlled motion delivering stitch precision and a minimum lubrication system.

The Durkopp Adler 867 is suitable for heavy-duty automotive and upholstery work through its walking foot technology, offering competitive material handling and durability comparison in commercial sewing machines.

Both industrial sewing machines use AC servo motors for motor efficiency and application versatility across fabrics.

Consew, TechSew, Reliable, and Highlead

You’ll find Consew durability shines with the T 1919’s precision on leather and upholstery, while TechSew specialization addresses saddlery and footwear with refined feed mechanisms. This brand comparison reveals clear advantages:

- Reliable features programmable back-tacking and thread trimming for productivity

- Highlead speed reaches industrial benchmarks with unison feed options

- Direct-drive servo motors reduce power consumption across Reliable and Highlead models

- TechSew machines excel at difficult materials requiring specialized handling

- Consew industrial sewing machines deliver consistent heavy duty performance for commercial applications

Global 1515 and Other Notable Machines

The Global WF 1515 features a walking foot needle feed with adjustable stitch length up to 9mm, delivering stitch precision through a 550W servo motor. Motor performance stays consistent at 2,500 stitches per minute, while vibration control maintains placement accuracy.

Your accessory kit includes a heavy-duty stand, oil, needles, and bobbins. When comparing best industrial sewing machine brands, this professional heavy-duty sewing machine accommodates thick assemblies with a 16mm presser lift height.

Innovations and Market Trends in Industrial Sewing

The industrial sewing world isn’t standing still—manufacturers are racing to build smarter, faster, and more efficient machines that can handle tomorrow’s production demands. From IoT-connected sensors that catch problems before they happen to AI-powered automation that takes precision to new levels, the technology driving these machines forward is genuinely impressive.

Let’s look at the key innovations and market shifts that are reshaping how industrial sewing machines operate today.

IoT Integration and Smart Sensors

Over 70% of textile mills now use IoT-enabled sensors for real-time monitoring of their industrial sewing machines, and you’ll see why this matters for your operation. These smart sensors track everything from thread tension to energy efficiency, while predictive maintenance alerts catch problems before they cause downtime—cutting breakdowns by 15% annually.

Process optimization happens automatically, and quality assurance improves through instant defect detection across your sewing equipment.

AI and Automation in Sewing Technology

You’re looking at a manufacturing revolution—AI-driven sewing stations can slash your labor costs by 50% while robotic sewing systems deliver 100% automated assembly.

Machine learning addresses automatic features like real-time stitch corrections and defect detection, boosting efficiency across industrial production processes.

This integration of AI with robotics transforms production flexibility, letting you switch between patterns instantly while maintaining automated quality control throughout your sewing technology workflow.

Growth in Global Market Demand

The industrial sewing machine market is projected to hit $6.04 billion by 2034, driven by e-retail expansion and fashion trends. Regional consumption remains concentrated—China, India, and the Philippines account for 34% of global demand.

Application segments like apparel manufacturing command 53% market share, while automotive and textile industry uses expand steadily.

Market restraints include high initial costs and automation challenges affecting commercial production uses across industrial applications.

Energy Efficiency and Modern Motor Designs

Servo motors deliver 70% energy savings compared to clutch motors, dropping consumption to just 1W when idle. Brushless motors improve sewing machine motor efficiency through direct drive systems that eliminate belt losses.

These energy-efficient innovations reduce your carbon footprint while cutting operational costs by up to 70%.

Motor technology innovations now include smart sensors that monitor performance and adjust power automatically for best efficiency.

Frequently Asked Questions (FAQs)

What are industrial sewing machines?

Built for production floors, these specialized machines stitch 600 to 8,500 stitches per minute—far outpacing household models.

Their cast-iron construction, weighing 40 to 950 kg, supports leather, canvas, and heavy fabrics continuously without overheating.

Which sewing machine is best for beginners?

You’ll want the SINGER 4423 or JUKI DDL 8700—they offer ease of use, reliable speed control, and sturdy all-metal construction. Both feature servo motor type options, manageable machine weight, and sufficient stitch options for confident learning.

What is the best industrial sewing machine?

The best industrial sewing machine depends on your project needs and budget.

For versatility and reliability, the Juki DDL-8700 excels with 5,500 stitches per minute, an energy-efficient servo motor, and heavy-duty construction ideal for professional applications.

What sewing machines do professionals use?

Professionals overwhelmingly reach for Juki DDL-8700, Brother S-7300, and Dürkopp Adler 867—machines that deliver superior stitch quality and motor efficiency.

These professional-grade sewing machines offer proven model reliability and remarkable machine lifespan for demanding industrial applications.

What is the best heavy duty sewing machine?

The Juki DDL-8700H addresses demanding applications with 5,500 stitches per minute and confronts multiple leather layers without hesitation.

Its metal frame construction and servo motor power deliver the reliability professionals need for continuous heavy-duty production.

What is the best industrial sewing machine 2025?

The Juki DDL-8700 leads 2025 industrial sewing machine comparisons with 5,500 stitches per minute, all-metal construction, and proven reliability.

User reviews and expert opinions consistently rank it among top performance benchmarks for choosing an industrial machine.

What is the typical power requirement for industrial sewing machines?

Most industrial sewing machines run on 110–120V or 220–240V with amperage ratings between 5 and 0 amps. Motor efficiency varies considerably—servo motors consume 60–70% less energy than clutch motors during operation.

What is the typical lifespan of industrial sewing machine needles?

Like tires on a high-performance race car, your industrial machine needles demand replacement every 6–8 hours of active sewing.

Material impact lifespan shrinks dramatically with heavy fabrics, while titanium coatings triple durability through modern needle tech innovations.

Can industrial sewing machines be used for embroidery?

Standard machines handle linear stitching, not the multi-directional patterns embroidery demands. Retrofit options exist but deliver limited stitch quality compared to dedicated embroidery equipment.

Automation differences mean purpose-built machines remain better for commercial sewing operations requiring intricate designs.

How much does an industrial sewing machine cost?

Prices swing from under $300 for entry-level lockstitch units to beyond $179,000 for automated bookbinding giants. Mid-range heavy-duty models generally run $1,299–$2,199, while used machine values hover around $400–$

Conclusion

Think of your production floor as a high-performance engine—it only runs as fast as its weakest component. Choosing from the best industrial sewing machines means investing in speed, durability, and precision that scales with demand.

Whether you’re stitching upholstery, leather, or technical textiles, the right machine doesn’t just keep pace—it sets it. Match your material, volume, and workspace to the specs that matter, and you’ll turn capability into capacity.

- https://www.gminsights.com/industry-analysis/industrial-sewing-machine-market

- https://www.indexbox.io/blog/industrial-sewing-machine-world-market-overview-2024-4/

- https://www.expertmarketresearch.com/reports/industrial-sewing-machines-market

- https://konsew.com/blog/what-is-the-best-industrial-sewing-machine-on-the-market-right-now

- https://www.nebraskaquiltcompany.com/blogs/welcome-to-nqc/brother-and-singer-a-comparison-of-industrial-sewing-machines-1