This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

They come with features like heavy-duty motors, walking feet, and larger needle sizes that are essential for working with tough materials. regular sewing machines can tackle some light upholstery work, but they may struggle with leather or multiple layers.

If you’re serious about upholstery, investing in a specialized machine will save you time, frustration, and potentially costly mistakes.

There’s a lot more to examine when choosing the right machine for your needs.

Table Of Contents

- Key Takeaways

- Do You Need a Special Sewing Machine for Upholstery?

- Upholstery Vs. Domestic Sewing Machines

- Must-Haves in an Upholstery Sewing Machine

- Recommended Upholstery Sewing Machines and Accessories

- Choosing the Best Upholstery Sewing Machine

- Recommended Upholstery Sewing Machine Brands

- Regular Sewing Machines for Auto Upholstery

- Advantages of Industrial Sewing Machines

- Considerations for Purchasing a Sewing Machine

- Tips for Using a Regular Sewing Machine

- Additional Information

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- While you can use a regular sewing machine for light upholstery work, investing in a specialized upholstery machine is like upgrading from a bicycle to a motorcycle – it’ll get the job done faster and more efficiently, especially when dealing with tough materials like leather or multiple layers.

- upholstery machines come with beefed-up features that’ll make your life easier: heavy-duty motors, walking feet, and larger needle sizes. It’s like having a superhero version of your trusty domestic machine, ready to tackle even the most challenging fabrics without breaking a sweat.

- When choosing an upholstery machine, consider your long-term goals and the types of fabrics you’ll be wrestling with most often. It’s like picking a dance partner – you want one that can keep up with your moves and won’t step on your toes when the tempo picks up.

- Don’t toss that old Singer machine just yet! With a little TLC and a professional once-over, it might surprise you with its ability to handle light upholstery work. It’s like finding out your grandpa’s vintage car can still burn rubber on the track.

Do You Need a Special Sewing Machine for Upholstery?

Yes, you generally need a special sewing machine for upholstery. While regular sewing machines can handle some light upholstery tasks, a specialized upholstery machine is designed to handle thicker fabrics, provide stronger stitches, and withstand the demands of heavy-duty upholstery work.

Upholstery Vs. Domestic Sewing Machines

When comparing upholstery and domestic sewing machines, upholstery machines operate at higher speeds and handle thicker, heavier fabrics with ease, making them ideal for demanding projects. These machines are built for durability and constant use, but they come with a higher price tag compared to domestic models.

Speed: Upholstery is Faster

Upholstery sewing machines work faster than domestic ones, making them ideal for:

- Automotive upholstery

- Leather handling

- Industrial efficiency

- Speed comparison

- Home use

They’re built for heavy-duty tasks.

Fabrics: Upholstery Can Handle Thicker, Heavier Fabrics

When working with heavy fabrics and thick materials, upholstery sewing machines excel, as they handle the durability of industrial-grade needles and thick threads. Here’s a quick comparison:

| Machine Type | Fabric Handling | Suitable Fabrics |

|---|---|---|

| Upholstery Machine | Heavy-weight fabrics | Leather, Canvas, Vinyl |

| Domestic Machine | Light to medium fabrics | Cotton, Linen, Silk |

Durability: Upholstery Can Withstand Constant Use

Upholstery machines are built for durability, handling heavy-duty materials with ease due to:

- Robust construction for constant use.

- Battery-powered options.

- Ergonomic design for user comfort.

Cost: Upholstery is More Expensive

Considering upholstery machines, they’re pricier upfront. Here’s a quick comparison:

| Feature | Upholstery Machine | Domestic Machine |

|---|---|---|

| Price | Higher | Lower |

| Durability | Excellent | Moderate |

| Fabric Choice | Thick, Heavy | Light, Medium |

| Speed | Faster | Slower |

| Stitch Length | Variable | Fixed |

Must-Haves in an Upholstery Sewing Machine

Your upholstery sewing machine needs to handle heavy-weight fabrics, accommodate upholstery thread, and have a servo motor for precise speed control. It also requires an industrial walking foot for uniform stitches and safety features to prevent bobbin messes.

Heavy-weight Fabric Handling

Handling heavy-weight fabric involves proper needle penetration, bobbin tension, and fabric preparation. Confirm that your machine can manage:

- Upholstery foam

- Vinyl

- Dense threads

Upholstery Thread Compatibility

Your machine must handle upholstery threads like 69-bonded nylon. Verify that thread strength matches needle thickness to maintain satisfactory bobbin quality and adjust thread tension.

Servo Motor for Speed Control

A servo motor offers precise speed control, ensuring consistent stitch quality. Unlike clutch motors, they’re quiet and ideal for walking foot sewing machines.

Industrial Walking Foot for Uniform Stitches

An industrial walking foot guarantees even feeding of materials, preventing puckers and providing uniform stitches. It’s essential for:

- Thicker fabrics

- Consistent tension

- Fabric layers

- Detailed projects

Safety Features to Prevent Bobbin Messes

Make certain your upholstery machine includes safety features like secure bobbin covers, smooth bobbin winding, and proper bobbin tension to prevent thread tangles and messes.

Recommended Upholstery Sewing Machines and Accessories

For upholstery projects, the Juki DNU 1541s offers a needle feed walking foot, ensuring uniform stitches even on heavy-weight fabrics. Complement this machine with 69-bonded nylon thread for durability, appropriate needle sizes (18 to 22), and specialized feet like cording, top stitch, and zipper feet for versatile applications.

Juki DNU 1541s: Needle Feed Walking Foot Machine

The Juki DNU 1541s stands out for its needle feed walking foot, upholstery thread compatibility, servo motor control, and essential safety features.

- Needle Feed System

- Walking Foot

- Servo Motor Control

- Safety Features

69. bonded Nylon Thread: Thick, Heavy-duty

69-bonded nylon thread is your go-to for upholstery, ensuring durability and strength. Ideal for heavy-duty fabrics, it’s perfect for industrial sewing tasks.

Needle Sizes: 18, 20, 21, 22

Next, you’ll need to assess needle sizes: 18, 20, 21, and 22. These provide the necessary strength and compatibility for heavy-duty upholstery fabric.

Cording Feet: 1/4 and 1/4 Double

You’re going to need cording feet, specifically 1/4" and 1/4" double cording, for heavy-duty cording applications. They guarantee clean, professional cording techniques.

Top Stitch Foot and Zipper Feet

Top stitch foot and zipper feet guarantee precise seams and smooth finishes. Ideal for:

- Even stitching

- Securing zippers

- Consistent pressure

- Accurate adjustments

Choosing the Best Upholstery Sewing Machine

When choosing the best upholstery sewing machine, consider your long-term upholstery goals, evaluate the fabrics you frequently use, and assess your production volumes. These factors will help you make sure you select a machine that’s durable, versatile, and capable of meeting your needs.

Consider Long-term Upholstery Goals

When considering long-term upholstery goals, assess your required fabric weight, thread compatibility, production volume, machine durability, and cost. Use the table below to guide your decision.

| Fabric Weight | Thread Compatibility | Production Volume | Cost |

|---|---|---|---|

| Heavy | High | Large | High |

| Medium | Moderate | Medium | Moderate |

| Light | Basic | Small | Low |

Evaluate Commonly Used Fabrics

Considering fabric selection is essential. Utilize heavy-weight fabrics, matching thread weight, and needles. Verify that the machine can manage thick materials such as leather or canvas without problems. Maintain appropriate stitch length and seam types for ideal upholstery outcomes.

Assess Production Volumes

Assess your production volumes to decide between an industrial or domestic machine. Higher volumes, thicker fabrics, and heavy-duty stitching favor industrial machines. Consider production planning, fabric selection, needle choice, thread tension, and seam allowance for satisfactory performance.

Recommended Upholstery Sewing Machine Brands

When considering upholstery projects, choosing specialized brands like Juki, Consew, and Sailrite guarantees dependable performance and durability. These brands are crafted to handle heavy fabrics and provide features that augment your sewing experience effectively.

Juki

Juki has a stellar reputation for quality and durability. Their warranties provide peace of mind, and the wide range of accessories guarantees flexibility. Juki’s machines, backed by excellent customer service, are perfect for professional upholstery projects.

Consew

Consew machines are another excellent option for upholstery work. Known for their durability and efficiency, they offer:

- Affordable price range

- Wide attachment compatibility

- Extensive warranty options

- Necessary accessories included

Consider Consew for your next upholstery project.

Sailrite

Sailrite offers premium upholstery sewing machines engineered for leather and heavy fabrics. Their machines excel in precision and durability, making them ideal for professional projects. With a Sailrite, you achieve consistent stitches and reliable performance, ensuring your work stands out.

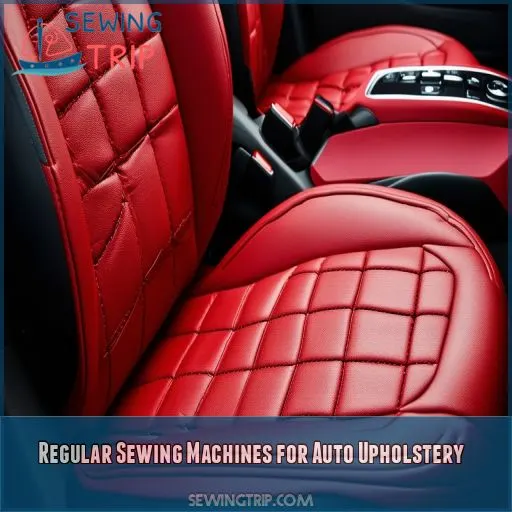

Regular Sewing Machines for Auto Upholstery

Regular sewing machines can be used for auto upholstery, though older models may be more powerful than newer ones, which may struggle with leathers and thick fabrics. Vintage Singer machines can work for light-duty upholstery tasks, but walking foot machines are necessary for professional-quality results, and welt foot machines are ideal for sewing welting or piping.

Can Be Used for Auto Upholstery

For auto upholstery projects, regular sewing machines can suffice, but walking foot machines guarantee even stitch quality on heavy fabrics.

Older Machines May Be More Powerful

Older machines may be more powerful with upholstery, offering strength and durability for:

- Leather

- Vinyl

- Heavy fabrics

Newer Machines May Struggle With Leathers and Thick Fabrics

Newer machines may struggle with leathers and thick fabrics due to limited needle strength, thread durability, and machine speed.

Vintage Singer Machines Suitable for Light Duty

Vintage Singer machines are great for light duty auto upholstery but make sure professional inspection before tackling door panel designs.

Walking Foot Machines Necessary for Professional Results

For professional results, walking foot machines guarantee even feeding, uniform stitches, and handle thick fabrics effortlessly.

Welt Foot Machines for Sewing Welting or Piping

To achieve clean, precise piping and welting, a welt foot attachment is essential, especially for professional auto upholstery results.

Advantages of Industrial Sewing Machines

Industrial sewing machines offer several advantages, including the ability to handle larger stitch gauges and heavy materials like leather. They minimize fabric movement with a walking foot and provide variable speed control through servo motors, unlike clutch motors with limited speed control.

Larger Stitch Gauges and Needles

Industrial sewing machines boast larger stitch gauges and needles, essential for maintaining stitch quality, handling heavy materials, and ensuring proper thread tension and needle selection.

Walking Foot Prevents Uneven Fabric Movement

A walking foot prevents uneven fabric movement, ensuring even feeding and uniform stitches. Industrial machines often include this feature for consistently professional results.

Can Handle Heavy Materials Like Leather

An industrial sewing machine handles heavy materials like leather with ease, thanks to its robust strength, walking foot compatibility, and overall durability.

Servo Motors Provide Variable Speed Control

Servo motors provide variable speed control, offering precise adjustments and smoother operation. Unlike clutch motors, they’re quieter and energy-efficient, ideal for heavy materials.

Clutch Motors Have Limited Speed Control

However, clutch motors have limited speed control, making detailed work challenging. Here are five drawbacks of clutch motors:

- Frequent stalling

- Inconsistent speed

- Noise issues

- Overheating risks

- Limited precision

Considerations for Purchasing a Sewing Machine

When choosing a sewing machine for upholstery, consider that clutch motors can stall on tight turns, while servo motors offer variable speed without a clutch. Always use fresh thread, as old thread can weaken over time, and remember that nylon thread is stronger than polyester, making it ideal for interior work.

Clutch Motors Can Stall on Tight Turns

Clutch motors can stall during tight turns, which disrupts your sewing rhythm. Adjust accordingly by practicing control techniques to finesse those tricky angles and maintain speed consistency.

Servo Motors Offer Variable Speed and No Clutch

Servo motors on sewing machines give you variable speed control, eliminating the clutch and making your work smoother, efficient, and precise. Consider these benefits:

- Consistent stitching.

- Quieter operation.

- Enhanced accuracy.

Discard Old Thread and Use Fresh

Using old thread can weaken your stitches and result in breakage. Always discard old thread and use fresh thread for better quality and durability in your upholstery projects.

Nylon Thread Stronger Than Polyester, Recommended for Interior Work

Nylon thread excels in strength, perfect for interior work and heavy fabrics. For upholstery projects and commercial use, it’s a top pick, ensuring durability and longevity in demanding applications.

Tips for Using a Regular Sewing Machine

When using a regular sewing machine for upholstery, practicing with vinyl before attempting leather can help you get accustomed to the material’s thickness and handling. Removing the face plate for larger stitches, modifying the feed dog plate, and using an electronic foot switch for better control are essential steps, while polyester thread guarantees UV resistance for outdoor applications.

Practice With Vinyl Before Leather

Before tackling leather, practice with vinyl. This guarantees you comprehend:

- Proper needle size and stitch length.

- Handling vinyl thickness.

- Fabric choice impact.

Remove Face Plate for Larger Stitch

Remove the face plate to achieve a larger stitch, enhancing needle clearance. This process aids in managing thicker materials effortlessly.

| Step | Tools Needed | Benefit |

|---|---|---|

| 1 | Screwdriver | Quick removal |

| 2 | Clean cloth | Remove debris |

| 3 | Small brush | Maintain cleanliness |

Modify Feed Dog Plate to Prevent Hitting

To prevent the feed dog from hitting, modify the feed dog plate. Feed dog adjustment and lubrication can guarantee smooth operation and stitch accuracy.

Use Electronic Foot Switch for Control

Using an electronic foot pedal offers greater foot control. Adjust pedal speed for precision, enabling smooth, variable-speed sewing, ideal for upholstery projects.

Polyester Thread UV Resistant for Outdoor Sewing

Using polyester thread guarantees your outdoor fabrics will withstand sun damage. Its thread durability and resistance to UV rays make it ideal for this purpose.

Additional Information

If you have an old Singer machine, don’t discard it just yet. You might be surprised to find it’s still functional for upholstery work with a professional inspection, and if you’re looking for inspiration, remember that door panel designs are available upon request.

Old Singer Machines May Be Functional With Professional Inspection

While exploring regular sewing machines, don’t overlook vintage Singer models. If you’re on a tight budget, these workhorses might be your ticket to upholstery success.

However, professional maintenance is imperative. A skilled technician can assess the motor, restore vintage components, and guarantee parts availability.

With proper care, these classic machines can tackle light upholstery work, offering a blend of nostalgia and functionality.

Door Panel Designs Available Upon Request

You’ll find a variety of door panel designs at your fingertips. From fabric colors to stitch patterns, you’ve got options galore. Consider thread thickness and needle gauge for your chosen design. Whether you’re aiming for classic or contemporary, there’s a style to suit your taste. Just ask, and we’ll help you craft the perfect look.

Frequently Asked Questions (FAQs)

What to look for in an upholstery sewing machine?

Look for a heavy-duty machine with a walking foot, strong motor, and larger stitch capacity. You’ll want compatibility with thick threads, adjustable speed control, and the ability to handle heavy fabrics like leather. Don’t forget safety features!

Will a regular sewing machine sew leather?

Like a hot knife through butter, a regular sewing machine can tackle leather, but with caveats. You’ll need the right needle, thread, and technique. For thicker hides, you’re better off with a heavy-duty or industrial machine.

Can you sew vinyl on a regular sewing machine?

You can sew vinyl on a regular sewing machine, but you’ll need some adjustments. Use a leather needle, longer stitch length, and walking foot. Go slow, adjust tension, and practice on scraps first. It’s doable, but challenges await!

Can you sew upholstery by hand?

You can sew upholstery by hand, but it’s challenging and time-consuming. You’ll need sturdy needles, heavy-duty thread, and a thimble. It’s best for small repairs or projects, not entire pieces. Consider a machine for larger tasks.

Do you need a sewing machine for upholstery?

You don’t absolutely need a sewing machine for upholstery, but it’ll make your life easier. While hand-sewing is possible, a machine, especially one designed for heavy fabrics, will save you time and guarantee stronger, more consistent stitches.

Can you sew upholstery without sewing?

You can tackle upholstery without sewing, but it’ll limit your options. Try no-sew methods like fabric glue, staples, or Velcro for simple projects. For durability and professional results, though, sewing’s your best bet. It’s worth learning the basics.

How to make a good upholstery sewing machine?

Picture a well-oiled machine humming with precision. You’ll need a heavy-duty motor, walking foot, and adjustable tension. Choose industrial-grade components, confirm proper alignment, and test rigorously. Regular maintenance keeps your upholstery sewing machine in top shape.

Why do upholstery sewing machines exist?

You’ll find upholstery sewing machines designed for heavy-duty tasks. They’re built to handle thick fabrics, multiple layers, and intense use. With stronger motors, larger needles, and specialized features, they’ll tackle your upholstery projects with ease and precision.

Do upholstery sewing machines come with extra features?

Yes, upholstery sewing machines come with specialized features. You’ll find walking feet for even fabric feeding, stronger motors to handle thick materials, and larger stitch lengths. They’re built tougher to withstand heavy fabrics and constant use.

What are upholstery sewing machines?

Upholstery sewing machines are heavy-duty tools designed to handle thick fabrics like leather and vinyl. They’ve got stronger motors, longer arms, and walking feet to tackle bulky materials. You’ll find them indispensable for professional-quality furniture and auto upholstery work.

Can I use a computerized sewing machine for upholstery?

Threading the needle of success, you’ll find computerized sewing machines can handle light upholstery tasks. However, they’re not built for heavy-duty fabrics. You’ll need a robust walking foot machine for professional-grade upholstery work. Consider your project’s demands carefully.

How much does a professional upholstery sewing machine cost?

Professional upholstery sewing machines typically cost between $1,000 and $5, You’ll find entry-level models around $1,500, mid-range options at $2,500-$3,500, and high-end industrial machines reaching $5,000 or more. It’s an investment in quality and durability.

Is it possible to rent an upholstery sewing machine?

Like finding a needle in a haystack, locating rental options for upholstery sewing machines can be challenging. You’ll find some specialty stores and equipment rental companies offer them. Check local upholstery shops, as they might rent out their machines during off-hours.

What maintenance is required for upholstery sewing machines?

You’ll need to oil your machine regularly, clean lint and debris, and replace needles often. Keep the tension balanced, check for loose screws, and lubricate moving parts. Don’t forget to clean the bobbin area and feed dogs thoroughly.

Can I convert a regular machine for upholstery work?

Ironically, you’d think converting a regular machine for upholstery would be a breeze. You can modify your existing machine, but it’s not ideal. Upgrade the needle, use heavier thread, and adjust tension. Consider a walking foot attachment for better results.

Conclusion

Imagine you’re restoring a vintage car’s interior. You’ll quickly realize that a special sewing machine for upholstery can be a game-changer. While not absolutely necessary, it’ll make your projects smoother and more professional.

Consider your long-term goals, fabric types, and production volumes when choosing a machine. Remember, regular sewing machines can handle light upholstery, but for serious work, investing in a specialized machine will save you time and frustration.

Ultimately, the right tool will elevate your upholstery projects to new heights.