This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A skipped stitch here, a puckered seam there—before you know it, your sewing project looks homemade in all the wrong ways, and the culprit is almost always the same: tension imbalance. Thread tension, the precise tug-of-war between your top and bobbin threads, determines whether your stitches lock smoothly inside the fabric or create loops and tangles on the surface.

When tension drifts even slightly out of balance, your machine fights against you instead of working with you, turning simple seams into frustrating puzzles. Learning how to adjust sewing machine tension transforms you from someone who hopes their stitches turn out right into someone who knows exactly which dial to turn when they don’t.

With the right adjustments and a systematic approach, you’ll troubleshoot tension problems in minutes instead of abandoning projects in defeat.

Table Of Contents

- Key Takeaways

- What is Sewing Machine Tension?

- Why Proper Tension Matters

- How Top and Bobbin Threads Interact

- Common Signs of Tension Problems

- Factors That Affect Sewing Machine Tension

- How to Check Sewing Machine Tension

- Step-by-Step: Adjusting Top Thread Tension

- Step-by-Step: Adjusting Bobbin Thread Tension

- Troubleshooting Persistent Tension Issues

- Maintaining Consistent Sewing Machine Tension

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Thread tension controls how tightly your top and bobbin threads pull against each other, and when balanced correctly, the threads lock precisely between fabric layers to create flat, professional seams without puckering or visible loops on either surface.

- Most tension problems stem from the top thread pathway, so start adjustments there using quarter-turn increments on the tension dial, testing on scrap fabric after each change, before touching the bobbin case screw, which requires even more precision.

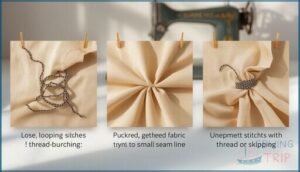

- Common warning signs of tension imbalance include visible loops on the fabric surface (indicating the opposite thread is too loose), puckered seams from excessive tightness, thread breakage, and skipped stitches that reveal severe mechanical issues beyond simple dial adjustments.

- Consistent tension maintenance requires rethreading your machine correctly with the presser foot up, cleaning lint from tension discs and the bobbin area every 8-10 hours of sewing, and keeping a log of successful settings for different fabric types and thread weights to eliminate guesswork on future projects.

What is Sewing Machine Tension?

Sewing machine tension controls how tightly your top and bottom threads pull against each other as they form stitches, and when it’s off, you’ll see loops, puckers, or weak seams that can ruin your project.

Most modern machines let you adjust tension with a numbered dial, and mastering thread tension tips helps you troubleshoot common issues quickly.

Understanding what tension actually is, how it affects your stitch quality, and the difference between top and bobbin thread tension will give you the foundation to troubleshoot problems confidently. Let’s break down the three key concepts you need to know before you start making adjustments.

Definition of Thread Tension

Thread tension is the relative tightness of sewing thread as it moves from the spool through guides to the needle, controlling thread flow and fabric tension.

Upper thread tension devices, such as discs and regulators, work with bobbin case springs to balance thread control.

Proper tension adjustment creates thread balance between upper and lower threads, ensuring consistent stitch quality when the needle penetrates fabric smoothly.

Knowing how to identify and correct common tension problems is essential for maintaining ideal stitch quality.

How Tension Affects Stitch Quality

When you master tension control, you achieve balanced stitch formation where threads lock precisely between fabric layers, creating a flat, professional seam that won’t pucker or pull.

Incorrect thread tension disrupts this balance, causing visible loops on the surface, fabric stretch along the seam line, or thread breakage that compromises sewing precision. Proper sewing machine tension ensures consistent stitch quality across every project you tackle.

Top Vs. Bobbin Thread Tension

Your machine relies on two tension systems working in concert: the upper thread controlled by the main dial, and the bobbin thread adjusted via the bobbin case screw. Understanding their distinct roles helps you achieve proper thread balance and stitch quality through precise tension control:

- Upper thread tension governs fabric interaction from above

- Bobbin thread tension controls underside stitch formation

- Tension adjustment of both creates centered thread lock

When you balance these systems, you master fabric interaction at every seam.

Proper maintenance and adjustment can help you address optimal bobbin tension settings for stronger, more consistent stitches.

Why Proper Tension Matters

When your sewing machine tension is dialed in correctly, you’ll create professional seams that hold up under stress and look clean on both sides of the fabric.

Get it wrong, and you’re looking at weak stitches that unravel, puckered seams that ruin the drape of your project, and visible thread imbalances that scream amateur work. Understanding why tension matters will help you troubleshoot problems before they sabotage hours of careful stitching.

Get tension wrong and you’ll face weak stitches, puckered seams, and visible thread imbalances that scream amateur work

Balanced Stitches and Seam Strength

When you set your tension correctly, you create balanced stitches that show equal loop formation on both fabric layers, which prevents seam curl and helps the finished piece lay flat.

This thread balance directly influences seam durability by distributing load evenly along the stitch line, so the seam resists tearing under force without unraveling.

Proper tension control maintains even bite depth through the cloth, which reduces visible stitch gaps and enhances fabric interplay after washing.

Consistent stitch formation prevents slippage at the seam edge, ensuring your seam holds through laundering and wear.

Effects of Incorrect Tension on Projects

Misalignment creates visible problems that spread beyond cosmetic frustration, so incorrect sewing machine tension directly damages seam integrity by weakening the thread lock that holds fabric layers together under stress.

When you ignore tension adjustment, you’ll see fabric distortion along curved edges, puckering effects that raise hill-like folds requiring extra pressing time, and thread fray near the needle eye that shortens needle life through increased friction.

Poor stitch quality produces uneven seam allowances that compromise garment fit, while loose thread tension on heavyweight material lets seams gape under load and eventually fail after washing cycles.

How Top and Bobbin Threads Interact

When you press the foot pedal and your machine starts stitching, two separate threads are working together beneath the fabric’s surface to form each stitch. The top thread follows a winding path from the spool down through various guides and tension discs before reaching the needle, while the bobbin thread sits in its case below, waiting to interlock with the top thread.

Understanding how these two threads meet and lock together will help you diagnose tension problems and make the right adjustments.

Thread Pathways in Sewing Machines

Your thread’s journey starts at the spool pin, then moves through thread guides toward the tension discs, which clamp down to control resistance.

From there, it travels up to the take-up lever, which lifts and feeds thread in rhythm with needle movement.

Meanwhile, the bobbin case releases bobbin thread upward through the shuttle hook, where both threads interlock in the fabric to create balanced stitches.

The Tug-of-War Effect

When balanced forces compete, you get a clean stitch; when they don’t, one thread shows where it shouldn’t. Think of tension dynamics as a contest where top and bobbin threads each pull against resistance to form a stable knot inside your fabric layers.

This sewing mechanics tug-of-war relies on:

- Equal pull from both threads to prevent looping or puckering

- Proper tension settings that match your fabric weight and thread type

- Coordinated resistance through calibrated discs and bobbin case springs

Achieving Middle Fabric Thread Lock

When top and bobbin threads meet precisely at the fabric surface, you’ve achieved middle lock—the balanced bite point where your stitches gain maximum strength without visible thread tails or puckering. This lock stability depends on tension tuning that situates the thread balance slightly below the fabric surface, creating a neat V-shaped stitch pattern through proper needle calibration and fabric interaction.

| Fabric Type | Top Tension Adjustment | Lock Characteristics |

|---|---|---|

| Burlap/Denim | Increase for firm hold | Durable, high-pull seams |

| Silk/Voile | Decrease to prevent pucker | Smooth, gloss-free finish |

| Knit Fabrics | Balance carefully for stretch | Flexible, movement-ready lock |

| Interfaced Layers | Standard or slight increase | Stable, rigid seam formation |

Achieving consistent middle lock requires you to match your bobbin thread tension with thread weight, then test adjustments on scrap fabric identical to your project material.

Common Signs of Tension Problems

Your machine will tell you when tension is off, but you need to know what to look for. These warning signs show up on your fabric while you’re stitching, and they’re often the first clue that something’s wrong with the thread balance.

Here are the three most common indicators that your tension needs adjustment.

Loops on Top or Bottom

Visible loops signal that your thread balance has gone awry, and when you spot them on either surface, you’re witnessing a clear breakdown in loop formation. Tension adjustments become necessary because the upper thread and bobbin thread aren’t meeting where they should—right in the middle of your fabric layers, where proper stitch quality depends on balanced fabric interaction.

- Loops on top mean your upper thread tension is too loose, so the bobbin thread pulls it downward and creates slack on the fabric surface

- Loops underneath indicate your lower thread tension is insufficient, allowing the upper thread to drag the bobbin thread upward through the fabric

- Consistent loops across a seam confirm your tension settings need immediate correction rather than sporadic rethreading

- Thread nests or bird’s nests on the underside result from severe bobbin thread slack combined with tight upper thread

- Visible light gaps when you hold fabric up reveal poor thread tension lock formation between layers

Puckering and Uneven Stitches

When your fabric gathers into tiny ridges along the seam line, you’re seeing seam puckering from excessive thread tension compressing the weave, or from stitch density that’s too high for lightweight materials.

Uneven stitches reveal tension balancing failures, where one thread pulls harder than the other, and proper tension adjustment corrects both issues by equalizing the fabric stretch relationship between your upper and bobbin threads during weaving.

Thread Breaking or Skipping

Thread breakage and skipped stitches signal severe tension imbalance, needle damage, or fabric slippage during the stitch cycle, where the needle fails to form proper loops or the thread snaps under excessive load at the eye or bobbin case.

Watch for these thread breaking and skipping indicators:

- Frequent snaps just above the needle eye

- Missed stitches where loops fail to catch

- Uneven stitch lengths with visible gaps

- Broken thread accumulating near tension discs

Factors That Affect Sewing Machine Tension

Your sewing machine’s tension doesn’t exist in a vacuum, and several external factors can throw off even a perfectly adjusted setting. Understanding what influences thread balance helps you diagnose problems faster and adjust with confidence instead of guessing.

Before you touch that tension dial, check these four elements that directly impact how your top and bobbin threads interact.

Thread Quality and Weight

You must match thread quality and weight to your fabric, because mismatched materials compromise stitch formation. Core spun polyester and filament threads behave differently under tension; core spun resists fraying while filament nylon glides smoothly through woven layers.

Weight measurement follows an inverse scale, where 40-weight general purpose thread suits medium fabrics, while 60 to 70-weight threads prevent puckering on delicate weaves. Thread selection and quality directly influence thread management and fiber strength in every seam.

Needle Size and Condition

Your needle selection plays a direct role in sewing machine tension balance, because a bent or dull needle disrupts stitch formation and causes thread fraying or fabric damage.

Replace needles after eight to twelve hours of sewing to prevent needle breakage and maintain needle sharpness, and verify that needle size matches your thread weight to minimize skipped stitches and tension inconsistencies.

Fabric Type and Thickness

Different fabric weights and fiber contents demand unique tension settings, because lightweight silks or chiffons require lower tension than heavyweight denim or canvas to prevent puckering or thread breakage.

Plain weaves usually need less tension adjustment than textured twills or pile knits, since knit structures with looped fibers compress differently under the presser foot and alter how threads lock in the middle of fabric layers.

Machine Cleanliness

Over time, accumulated lint and dust in your bobbin area, feed dogs, and tension discs will restrict thread movement and create irregular stitches, which is why machine maintenance, dust removal, and lint control matter as much as calibration.

Use machine covers during storage, follow cleaning schedules from your manual, and schedule sewing machine repair when troubleshooting reveals worn parts affecting tension consistency.

How to Check Sewing Machine Tension

Before you can adjust your tension, you need to know what you’re looking at. The best way to test your machine’s tension is to sew a sample seam and examine the stitches on both sides of the fabric.

Here’s how to run a proper tension check.

Using Contrasting Threads for Clarity

You can diagnose sewing machine tension faster when you load a light thread in the needle and a dark thread in the bobbin, because this contrast stitching creates a visual tension map across your fabric. Thread color choice reveals exactly where the threads interlock—ideal stitches show both colors meeting inside the fabric weave, while misaligned tension makes one color dominate the visible surface.

This diagnostic threading technique, also called color coding techniques, eliminates guesswork during tension adjustment by transforming invisible mechanical problems into clear, immediate visual feedback you can photograph and compare across multiple test runs.

Assessing Stitch Appearance

Stitch quality reveals itself through careful visual inspection of your seam after completing a test line of stitches, because balanced sewing machine tension produces neat, uniform loops that lie flat against both fabric surfaces without pulling fibers upward. You should examine the right side for small, consistent stitches showing minimal thread visibility, while the underside displays a nearly invisible bobbin line when tension settings align correctly.

Puckering control depends on recognizing fabric distortion early—tight tension creates small wrinkles along lightweight fabrics, while loose tension generates loopy horizontal stitches compromising seam consistency across your entire project.

Step-by-Step: Adjusting Top Thread Tension

Adjusting your top thread tension is the first and most effective move when you’re chasing down stitch problems, since most tension issues live in the upper thread pathway.

You’ll need to locate your machine’s tension dial, understand which direction tightens or loosens the thread, and test your adjustments on scrap fabric until the stitches balance out. Here’s how to take control of your top tension settings step by step.

Locating and Using The Tension Dial

Your tension dial sits on the top right of most machines near the needle area, often labeled with numbers that guide your Thread Tension Adjustment choices. Before adjusting, rethread both the top thread and bobbin to guarantee the tension regulator responds accurately to your changes.

Turn the dial gradually in increments of one or two settings while testing on scrap fabric, which prevents large jumps that can damage delicate projects. When you’re finished sewing, return the tension dial to a neutral baseline to avoid accidental shifts during your next session, and keep the dial area free of lint by cleaning after every few projects.

Increasing or Decreasing Tension

Your tension regulator reacts to quarter-turn adjustments that shift Thread Balance without shocking delicate thread through the tension discs, which means you’ll increase Fabric Tension by rotating the dial clockwise to higher numbers or tighten the tension control mechanism incrementally. To decrease tension and improve Stitch Quality on lightweight materials, turn counterclockwise toward lower settings while monitoring thread flow through each adjustment cycle.

- Start with ¼ turn increments to prevent overcorrection

- Test each Thread Tension Adjustment on scrap fabric before continuing

- Increase tension when bobbin thread shows on the fabric surface

- Decrease tension if puckering appears or top thread loops

- Record successful Sewing Techniques settings for future reference

Step-by-Step: Adjusting Bobbin Thread Tension

Adjusting the bobbins tension requires more precision than working with the top thread, because even small turns of the bobbin case screw can dramatically alter stitch balance. You’ll need to locate the tiny adjustment screw on your bobbin case, then turn it in quarter-turn increments while testing frequently on scrap fabric.

The direction you turn this screw determines whether you tighten or loosen the bobbins thread, so understanding clockwise versus counterclockwise movement is essential.

Identifying The Bobbin Case Screw

Before you can make any tension adjustment, you need to locate the small screw that controls thread balance on your bobbin case. In front loading sewing machine systems, look for a tiny flat head or Phillips screw on the side of the bobbin case housing, usually positioned beside the spring guides.

Some models conceal the screw under a removable cap or cover plate, so consult your manual if it’s not immediately visible. This tension regulator screw is small and requires a precision screwdriver for proper engagement when adjusting.

Adjusting Clockwise Vs. Counterclockwise

Once you’ve found the tension regulator screw, understanding rotation is the key to controlled adjustment. Thread tension behaves like any mechanical fastener, so clockwise turns tighten the spring pressure on your bobbin thread while counterclockwise rotation loosens it.

Here’s how direction basics work for tension adjustment:

- Turn clockwise (right) to increase bobbin thread tension when you see loose loops on the fabric underside

- Turn counterclockwise (left) to decrease tension if the bobbin thread pulls too tight

- Make quarter turn increments, testing on scrap fabric between adjustments

- Reset to baseline if overcorrection occurs during sewing techniques practice

Troubleshooting Persistent Tension Issues

When you’ve adjusted both the top tension and bobbins tension but your stitches still won’t cooperate, the problem often lies somewhere else in the machine’s threading system or mechanical system.

Before you assume your machine is broken, you can methodically check three common culprits that masquerade as tension issues. Each of these checkpoints takes just a few minutes but can save you hours of frustration and unnecessary adjustments.

Rethreading The Machine Correctly

Before adjusting tension dials, remove your thread from the sewing machine entirely and rethread from scratch, because incorrect thread alignment or needle security often masquerades as a tension balance problem.

Pull both thread tails through their guides with your presser foot up, seat the needle firmly in its clamp, and confirm the take-up lever captures the thread before testing stitches.

Checking Bobbin Winding and Installation

Pull your bobbin out and inspect the winding techniques—look for gaps, overlaps, or loose tails that throw off thread tension during stitching.

Rewind if the thread looks uneven, then reinsert the bobbin with its flat side oriented correctly, confirming the bobbin thread exits through the proper slot. Rotate the handwheel gently to verify smooth engagement, because misaligned installation tips can mimic tension imbalance even when your adjusting dials are correct.

Inspecting for Damaged Parts

Beyond winding and bobbin placement, visual inspection reveals hidden culprits—check your needle plate for cracks that snag thread, examine tension discs for shiny wear patterns indicating component wear, and look for bent feed dogs or damaged thread guides.

These defects cause thread damage no amount of adjusting can fix, so part replacement becomes necessary. Regular machine maintenance prevents most wear, but catching issues early saves frustration when tension problems persist despite correct bobbin and dial settings.

Maintaining Consistent Sewing Machine Tension

Once you’ve nailed down your machine’s tension settings, the real challenge is keeping them that way.

Consistency doesn’t happen by accident—it requires a few simple habits that prevent drift and catch problems before they derail your projects.

Here’s how to maintain stable tension over the long haul.

Regular Cleaning and Oiling

Regular cleaning and oil maintenance form the backbone of sewing machine maintenance, and they directly prevent tension irregularities that derail your projects.

Clean the bobbin area and feed dogs every 8 to 10 hours of sewing, removing lint with a soft brush or canned air to maintain sewing machine tension stability. Apply machine oil to moving parts every 8 to 12 hours, using light mineral oil or manufacturer-recommended lubricant types for consistent performance.

Keeping a Tension Log

Documentation transforms guesswork into precision when you keep a tension log for every sewing session, recording fabric type, thread weight, and exact tension dial settings in a notebook or digital file.

This Tension Tracking practice lets you compare stitch samples side by side, analyze thread monitoring outcomes, and build a fabric profiling reference that ensures repeatable stitch quality across projects without recalibrating tension discs each time.

Consulting The Machine Manual

Your machine manual delivers model-specific Manual Guidance that maps exact Thread Paths from spool to needle, pairs fabric types with precise Tension Settings, and outlines Adjustment Techniques using diagrams you won’t find elsewhere.

It explains how cleaning tension discs affects Sewing Machine Tension over time, provides Maintenance Tips for bobbin adjustment screws, and offers troubleshooting steps that address your exact Sewing Machine Settings and Adjustments when standard methods fail.

Frequently Asked Questions (FAQs)

How to tell if sewing machine tension is right?

You’ll know sewing machine tension is right when both sides of your fabric show equal thread visibility, stitches lie flat without puckering, and the thread lock forms in the middle of the fabric layers.

Why is my sewing machine looping underneath?

Looping underneath signals top thread tension is too loose, allowing slack that the bobbin can’t pull tight, or your tension discs need cleaning to grip the thread properly for balanced fabric interaction.

What is sewing machine tension adjustment?

Finding the sweet spot isn’t just lucky—it’s science. Adjusting sewing machine tension means calibrating tension discs and bobbin resistance to balance thread interaction, ensuring stitch formation locks evenly within fabric layers for ideal machine performance.

How to adjust Tension in Sewing Machine?

Start by rethreading your sewing machine from spool to needle, ensuring thread seats correctly between tension discs.

Then test fabric stretch and needle tension using scrap material before adjusting the dial incrementally.

How to fix a sewing machine stitch Tension Problem?

Like untangling a stubborn knot, fixing stitch tension problems requires rethreading your machine with the presser foot up, cleaning tension discs, replacing bent needles, and testing thread balance using fabric scraps.

How do I know if my sewing machine is tight?

Your machine shows tightness through compact stitches that barely form, visible thread crush along seam lines, or puckered fabric edges—all tension indicators requiring thread balance checks and calibration before adjusting tension settings.

How do I set the tension on my sewing machine?

Set your tension dial to the middle position, usually 4 or 5, then sew a test stitch on scrap fabric using contrasting thread colors to evaluate thread balance and make small adjustments as needed.

How do I adjust the pressure on my sewing machine?

Locate the presser foot pressure dial on your machine’s top or side, then turn it clockwise to increase grip on thick fabrics or counterclockwise to reduce pressure for delicate materials.

Why does my sewing machine skip stitches?

Skipped stitches occur when a bent needle fails to form proper thread loops, when incorrect threading leaves slack, or when feed dogs can’t grip fabric due to wrong presser foot pressure.

How often should tension be checked?

The less you check, the more you’ll need to—neglecting sewing machine tension invites trouble.

Perform tension check frequency at least monthly for regular sewing, weekly when switching fabrics or thread weights, and always before major projects.

Conclusion

Nothing derails a sewing project faster than tension troubles that leave you second-guessing every stitch.

Once you know how to adjust sewing machine tension—turning the right dial, reading your fabric’s signals, checking bobbin alignment—you won’t just fix problems, you’ll prevent them.

Your machine becomes an ally instead of an obstacle, delivering clean seams every time. Master tension adjustments now, and you’ll sew with confidence that transforms fabric into finished pieces worth showing off.