This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

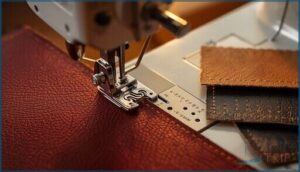

Most standard sewing machines give up around the fourth layer of leather layers—the motor strains, the needle bends, and your project stalls mid-seam.

Professional upholsterers and leather workers know this frustration well, which explains why industrial machines with 550 to 800 watts of motor power dominate serious workshops.

The difference between struggling through thick materials and achieving clean, consistent stitches comes down to specific mechanical capabilities: walking foot systems, adjustable presser foot pressure, and needles rated for penetrating multiple leather layers.

Whether you’re restoring automotive interiors or crafting custom saddles, your machine selection determines both the quality of your finished work and how many hours you’ll spend fighting skipped stitches and thread breaks.

Table Of Contents

- Key Takeaways

- What Makes a Sewing Machine Ideal for Leather and Upholstery

- Top 9 Sewing Machines for Leather and Upholstery

- 1. Industrial Heavy Duty Sewing Machine

- 2. Industrial Strength Leather Sewing Machine

- 3. Heavy Duty Leather Sewing Machine

- 4. Xuthusman Industrial Sewing Machine

- 5. Janome Heavy Duty Sewing Machine

- 6. Juki Portable Sewing Machine

- 7. Singer Heavy Duty Sewing Machine

- 8. Brother Heavy Duty Sewing Machine

- 9. Brother Sewing Machine XM2701

- Essential Features for Leather and Upholstery Sewing

- How to Sew Leather and Upholstery Successfully

- Maintenance and Care for Leather Sewing Machines

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Motor power between 550 and 800 watts with walking foot systems separates machines that consistently penetrate multiple leather layers from domestic models that stall on thick materials.

- Industrial machines deliver durability through cast iron frames and reinforced components, while domestic heavy-duty models use lighter aluminum construction that limits their capacity for continuous professional upholstery work.

- Proper needle selection (90/14 to 110/18 sizes) paired with bonded polyester or nylon thread (Tex 30 to Tex 92) prevents skipped stitches and maintains seam integrity across varying leather thickness.

- Regular maintenance including daily lint removal, oil checks every 20 to 40 hours, and needle replacement every six to eight hours of active use extends machine lifespan and prevents costly breakdowns during heavy material projects.

What Makes a Sewing Machine Ideal for Leather and Upholstery

Working with leather and upholstery demands equipment built to handle punishment that would destroy a standard machine. You can’t expect consistent results when your machine struggles with thick hides or multiple fabric layers.

Professional computerized embroidery machines designed for heavy materials include reinforced needle bars and adjustable presser foot pressure to maintain precision even through dense leather.

Leather and upholstery work demands machines built to withstand punishment that would destroy standard equipment

Understanding the core specifications that separate capable machines from inadequate ones will save you from costly mistakes and project failures.

Motor Power and Speed Requirements

You’ll need at least 550 to 800 watts of motor power to push through multiple layers of leather without stalling.

Industrial sewing machines deliver one to two horsepower with constant torque output, ensuring stitch precision across thickness transitions.

Speed control from 400 to 1500 stitches per minute gives you the flexibility for detailed topstitching or high-volume upholstery work, while direct drive systems optimize motor efficiency.

For more technical details, you can learn about motor torque and speed requirements as they relate to sewing machine motors.

Needle and Thread Capacity for Thick Materials

Thick material demands needle sizes ranging from 90/14 to 110/18 for clean penetration through leather layers. Your machine must accommodate bonded nylon or polyester threads from Tex 30 to Tex 92, which deliver the tensile strength heavy duty sewing requires. Thread tension adjustments prevent loose top stitches and puckering, while proper needle compatibility ensures consistent stitch balance across varying material thickness without shredding or skipped stitches. For deeper insight, review the impact of on both fabric quality and sewing machine performance.

- Match needle size to leather thickness to avoid deflection or breakage

- Use bonded polyester or nylon threads for exceptional seam strength

- Adjust thread tension to balance stitch formation on thick layers

- Select needles with larger eyes to reduce friction during fabric feed

Feed System and Walking Foot Mechanism

Walking foot mechanisms grip fabric with synchronized teeth on top and bottom to feed multiple layers evenly through industrial sewing machines.

You’ll notice dual feed systems match top advancement with lower feed dogs, preventing leather and foam from shifting during heavy duty sewing.

Adjustable presser foot pressure compensates for varying thickness, maintaining fabric control and stitch consistency across rigid upholstery materials without puckering or misalignment.

Frame Construction and Durability Standards

Your machine’s frame construction determines whether it survives years of leather work or fails under stress. Heavy duty sewing machines use high tensile steel frames with reinforcement plates at stress points to resist bending forces during thick material penetration.

Industrial sewing machines incorporate vibration dampening through cast iron bases and balanced motor mounts, maintaining stitch alignment within ±0.2 mm at top speed while preventing fatigue-related deformation over millions of cycles.

Domestic Vs Industrial Sewing Machines

Your choice between domestic and industrial leather sewing machines hinges on machine comparison across critical performance factors. Industrial sewing machines deliver continuous torque exceeding 1000 stitches per minute through powerful motor types, while heavy duty sewing machines designed for home use usually cap at 600-900 SPM with lighter frame materials and simpler user interface controls for upholstery sewing machine selection.

- Industrial units feature cast iron frames and walking foot systems for consistent leather feeding

- Domestic models use aluminum or plastic construction to reduce weight and cost

- Industrial machines require specialized electrical installations and professional maintenance schedules

- Domestic sewing machines ship ready for standard household power with accessible user servicing

Top 9 Sewing Machines for Leather and Upholstery

You need the right equipment to handle thick leather and upholstery materials without compromise. The machines below represent proven options across industrial and heavy-duty categories, each designed for specific material weights and project requirements.

Your choice depends on workspace constraints, material thickness, and whether you’re running commercial operations or tackling personal projects.

1. Industrial Heavy Duty Sewing Machine

You need a machine that can handle long shifts without breaking down. The GOSHET industrial heavy duty sewing machine delivers with a cast iron shell and aluminum construction built for durability.

It reaches speeds up to 3,000 stitches per minute through its double thread rotary hook system. The automatic oil spraying device maintains lubrication while keeping noise levels low during operation.

With adjustable needle length up to 0.3 inches and a lower feeding method, you’ll handle medium and thick fabrics smoothly in upholstery shops or alteration stores.

| Best For | Upholstery shops and alteration businesses that need a durable machine capable of handling medium to thick fabrics at high speeds. |

|---|---|

| Material | Aluminum, Cast Iron |

| Max Speed | 3000 stitches/min |

| Weight | 66.8 pounds |

| Power Source | No motor included |

| Use Case | Industrial upholstery |

| Skill Level | Beginners, Professionals |

| Additional Features |

|

- Reaches up to 3,000 stitches per minute with a double thread rotary hook system for fast, efficient work

- Cast iron and aluminum construction built to withstand heavy industrial use over time

- Automatic oil spraying keeps the machine lubricated and quiet during long shifts

- No motor included, so you’ll need to purchase one separately

- Limited to medium and thick fabrics—not ideal if you work with lightweight materials

- Weighs nearly 67 pounds, making it difficult to move or reposition

2. Industrial Strength Leather Sewing Machine

You’ll power through heavyweight leather projects with the Industrial Strength Leather Sewing Machine, built with high-quality cast iron for vibration dampening during extended sessions. It processes materials up to 4mm thick at speeds reaching 2,000 stitches per minute.

The manual presser foot spanner clamps thread spools securely, while clearly marked gauge chucks simplify adjustment of sewing direction. Its reverse stitch switch reinforces seams effectively, and the DP5 14 needle penetrates dense hides without hesitation across garment factories and home workshops.

| Best For | Professional sewers and serious hobbyists who regularly work with thick materials like leather, canvas, and upholstery fabric. |

|---|---|

| Material | Cast Iron |

| Max Speed | 2000 stitches/min |

| Weight | Not specified |

| Power Source | Motor not included |

| Use Case | Thick materials |

| Skill Level | Enthusiasts, DIY |

| Additional Features |

|

- Handles heavy-duty materials up to 4mm thick at an impressive 2,000 stitches per minute

- Durable cast iron construction reduces vibration and ensures long-term reliability

- Reverse stitch function and adjustable gauge chucks make it versatile for different projects

- Requires separate purchase of motor and tabletop frame to operate

- Assembly must be done carefully to avoid safety issues and personal injury

- Missing safety devices in the base package means additional investment needed

3. Heavy Duty Leather Sewing Machine

You’ll tackle demanding leather projects with the Heavy Duty Leather Sewing Machine (GK9-890), featuring aluminum construction that keeps the 6.3-pound unit portable without sacrificing performance. Its powerful motor delivers 1,800 stitches per minute through thick fabrics, while adjustable stitch length accommodates varying material thicknesses.

The machine offers manual and automatic secant modes for closing bags and repairing upholstery efficiently. At $89.01, this compact 9.84 x 9.84 x 3.14-inch model processes woven bags and cloth materials effectively, though it’s limited to loop stitching rather than adaptable leather garment work.

| Best For | Small business owners and DIY enthusiasts who need to seal bags, sacks, and packaging materials quickly rather than craft leather goods. |

|---|---|

| Material | Aluminum |

| Max Speed | 1800 stitches/min |

| Weight | 6.3 pounds |

| Power Source | Electric |

| Use Case | Bag sealing |

| Skill Level | Heavy-duty use |

| Additional Features |

|

- Blazing fast at 1,800 stitches per minute, making bag-closing operations efficient for high-volume work

- Lightweight at 6.3 pounds with a compact footprint, so you can move it around your workspace easily

- Budget-friendly at $89.01 considering the industrial-grade motor and aluminum build quality

- Despite the “leather” label, it’s actually limited to loop stitching for bag closures—not suitable for actual leather crafting

- Lacks stitch variety, so you’re stuck with one stitch type instead of having creative options

- Customer reviews suggest it underdelivers on advertised capabilities, particularly for leather applications

4. Xuthusman Industrial Sewing Machine

You’ll command true industrial capability with the Xuthusman Industrial Sewing Machine, engineered for commercial upholstery environments requiring continuous eight-hour duty cycles.

Its 550-watt motor drives speeds up to 3,500 stitches per minute through materials measuring 0.2 inches thick, while the cast iron frame dampens vibration during high-speed operation.

The machine’s integrated walking foot system prevents slippage across multiple leather layers, and its adjustable stitch length accommodates varying hide thicknesses. At 30 decibels, this unit operates quieter than most industrial models while maintaining professional-grade performance standards.

| Best For | Professional tailors, upholstery shops, and clothing manufacturers who need a heavy-duty machine that can handle thick materials and run continuously for extended production shifts. |

|---|---|

| Material | Iron, Aluminum |

| Max Speed | 3500 stitches/min |

| Weight | Not specified |

| Power Source | AC110V Electric |

| Use Case | Professional tailoring |

| Skill Level | Professional, DIY |

| Additional Features |

|

- Blazing fast at 3,500 stitches per minute with a powerful 550W motor that chews through materials up to 0.2 inches thick

- Surprisingly quiet at 30dB despite industrial-grade performance, so you won’t go deaf during long work sessions

- Built like a tank with cast iron construction that keeps things stable even when running at maximum speed

- Requires some setup work and maintenance—you’ll need to oil it with white oil before first use and keep up with lubrication

- Not exactly plug-and-play; there are specific operating rules (like counterclockwise rotation only) that could damage the machine if ignored

- Controller settings are off-limits, which limits your ability to customize or troubleshoot without potentially causing system problems

5. Janome Heavy Duty Sewing Machine

The Janome Heavy Duty delivers sturdy metal frame construction that stabilizes high-speed stitching through denim and moderate-weight leather materials without excessive vibration. You’ll access 18 built-in stitches with a maximum width of 6.5mm and length of 4mm, supported by adjustable foot pressure for material thickness control.

Its 23-pound aluminum and plastic housing accommodates straight stitch performance on upholstery projects, though the limited harp space restricts bulky item maneuvering. The machine’s corded electric power maintains consistent needle penetration across heavy fabrics when paired with appropriate needle sizes.

| Best For | Sewers who need a reliable workhorse for heavy fabrics like denim and leather but don’t require quilting features or a large workspace. |

|---|---|

| Material | Aluminum, Plastic |

| Max Speed | Not specified |

| Weight | 23 pounds |

| Power Source | Corded Electric |

| Use Case | Heavy-duty sewing |

| Skill Level | Beginners, Experienced |

| Additional Features |

|

- Metal frame construction keeps the machine stable when sewing through thick materials at high speeds

- 18 built-in stitches with adjustable foot pressure give you flexibility for different fabric weights

- Straightforward design makes it easy to use whether you’re a beginner or experienced sewer

- Small harp space makes it difficult to work on quilts or larger projects

- Three-step buttonhole process is less convenient than one-step systems on other machines

- Stitch selector display is hard to read without extra lighting

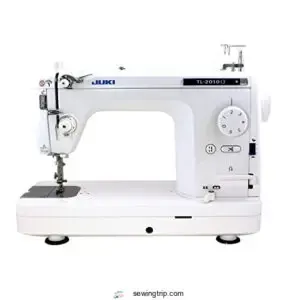

6. Juki Portable Sewing Machine

The Juki TL-2010Q combines portability with industrial-grade performance, weighing just 38 pounds in its aluminum frame while delivering automatic thread trimming and needle threading features that reduce setup time.

You’ll achieve stitch speeds suitable for leather and upholstery work when you pair it with size 100/16 needles and heavy-duty thread. Its knee lifter lever provides hands-free presser foot control during bulky material handling, though you’ll need proper tension adjustments to prevent thread breakage on thick leather layers.

| Best For | Quilters and sewers who need industrial-strength performance in a portable machine and value automatic features like thread trimming and needle threading. |

|---|---|

| Material | Aluminum |

| Max Speed | Not specified |

| Weight | 38 pounds |

| Power Source | Electric |

| Use Case | Quilting |

| Skill Level | Advanced |

| Additional Features |

|

- Automatic thread trimming and needle threading save time between seams

- Knee lifter lever lets you control the presser foot hands-free while handling bulky fabrics

- Lightweight aluminum frame (38 lbs) makes it easy to move or store compared to heavier industrial machines

- Doesn’t include a dedicated scant 1/4″ foot, which quilters often need

- Lighting isn’t as bright as some users would prefer for detailed work

- Needle threader can be tricky to master and may require practice to use smoothly

7. Singer Heavy Duty Sewing Machine

Singer Heavy Duty machines deliver up to 1,100 stitches per minute through their high torque motors rated between 60 and 110 watts, pushing through multiple leather layers without stalling. The metal interior frame and stainless steel bed plate reduce vibration during high-speed stitching on heavy materials.

You’ll find the extra high presser foot lift essential when positioning thick leather, while the adjustable foot pressure optimizes feeding through vinyl and canvas. This model accepts needles in the 90/14 to 110/18 range for varied fabric thickness.

| Best For | Sewists who need a reliable workhorse for thick fabrics like denim, canvas, and multiple layers of leather without worrying about the machine stalling or struggling. |

|---|---|

| Material | Metal, Plastic |

| Max Speed | 1100 stitches/min |

| Weight | 14.6 pounds |

| Power Source | Corded Electric |

| Use Case | Heavy-duty projects |

| Skill Level | Beginners, Experienced |

| Additional Features |

|

- Powerful motor handles heavy-duty materials at speeds up to 1,100 stitches per minute without bogging down

- Metal frame and stainless steel bed plate keep everything stable when you’re running through thick seams

- Extra high presser foot lift and adjustable pressure make it easy to work with bulky fabrics

- Some users run into timing and tension problems that need troubleshooting

- Regular cleaning is a must to prevent oil buildup and keep things running smooth

- Doesn’t always come with all the specialty feet you might want for different projects

8. Brother Heavy Duty Sewing Machine

Brother Heavy Duty models feature metal frames and internal gears that withstand the vibration and stress of continuous upholstery work. You get 37 built-in stitches with an automatic needle threader and drop-in bobbin system, reducing setup time when switching between leather and fabric layers.

The machine accommodates needles up to 100/16 size and maintains 800 stitches per minute through denim and lightweight leather. Adjustable presser foot pressure and a free arm design give you control when sewing sleeves, hems, and curved upholstery pieces without skipped stitches.

| Best For | Sewers who need a reliable workhorse for heavy fabrics like denim, canvas, and lightweight leather, whether you’re a beginner tackling your first upholstery project or an experienced crafter working on multiple layers. |

|---|---|

| Material | Metal |

| Max Speed | 800 stitches/min |

| Weight | 18.4 pounds |

| Power Source | Corded Electric |

| Use Case | Everyday sewing |

| Skill Level | Beginners, Experienced |

| Additional Features |

|

- Metal frame and internal gears handle thick fabrics without skipping stitches or slowing down

- Automatic needle threader and drop-in bobbin make setup quick when switching between different materials

- 800 stitches per minute with adjustable presser foot pressure gives you speed and control on everything from silk to outdoor canvas

- Buttonhole feature can be finicky and often needs manual tweaking to get right

- Some users report a burning plastic smell from the foot pedal during extended use

- Customer support and warranty claims can be hard to navigate, with limited help from the seller

9. Brother Sewing Machine XM2701

The XM2701 provides 27 built-in stitches and an automatic needle threader for everyday leather craft and upholstery repair. You work with a top drop-in bobbin system and six interchangeable presser feet, including a zipper foot and buttonhole foot for detailed work.

This machine processes medium-weight leather at 800 stitches per minute with adjustable stitch length up to 4 millimeters. The LED work area and free arm design support accurate stitching on sleeves and curved upholstery sections without repositioning.

| Best For | Beginners and intermediate sewers looking for a versatile machine that handles everyday projects like hemming, quilting, and decorative stitching without a steep learning curve. |

|---|---|

| Material | Metal |

| Max Speed | Not specified |

| Weight | 12.6 pounds |

| Power Source | Corded Electric |

| Use Case | Everyday sewing |

| Skill Level | Beginners, Advanced |

| Additional Features |

|

- 27 built-in stitches with automatic needle threader and one-step buttonholer make setup quick and eliminate common frustrations

- Six included presser feet cover most projects right out of the box, from zippers to buttonholes

- Lightweight at 12.6 pounds with a free arm design for easy maneuvering on sleeves and cuffs

- Spool pin can feel flimsy and may break with regular use

- Struggles with very thick or heavy fabrics where the presser foot becomes hard to control

- Some features require consulting the manual or online tutorials to figure out initially

Essential Features for Leather and Upholstery Sewing

Working with leather and upholstery demands specific machine capabilities that separate casual home models from serious workhorse equipment. Your sewing machine needs the right combination of mechanical adjustments, specialized components, and control features to handle thick materials without jamming or skipping stitches.

These five essential features determine whether you’ll achieve professional results or struggle through every seam.

Stitch Length and Presser Foot Adjustment

You control seam quality on leather and upholstery through precise stitch length and presser foot adjustments. Set stitch length between 2.5 and 3.0 mm for thick materials to prevent perforation while maintaining durability.

Adjust presser foot pressure higher for heavy-duty sewing to grip dense leather firmly without crushing thinner hides. Proper stitch control and fabric feeding prevent skipped stitches and maintain consistent thread tension throughout your leather sewing projects.

Specialized Needles and Feed Dogs

You match needle materials to leather density using sharp wedge point needles sized 90 to 110 for veg tanned hides. Titanium coated needles resist wear when sewing dense upholstery, while feed dog variants like Teflon coated designs prevent sticking on glossy leather.

Thread compatibility depends on weight—Tex 60 to Tex 120 polyester accommodates heavy duty sewing without breakage. Needle plate designs with larger openings accommodate thicker needles during leather sewing machine operation.

Walking Foot for Even Fabric Feeding

You need a walking foot feed system on upholstery sewing machines to eliminate fabric shifting during heavy duty sewing.

The dual feed dogs grip both top and bottom leather layers, ensuring even stitching across thick hides without misalignment. This synchronized fabric feeding prevents puckering on textured materials and maintains pattern alignment when working with multiple layers in leather sewing projects.

Speed Control and Reverse Stitching

You’ll find that precise sewing speed and reliable reverse stitch capability separate average machines from true leather sewing machine performers.

Motor response determines how smoothly you shift between forward and reverse on heavy duty sewing, while adjustable speed limits prevent sudden jumps that can tear thick hides.

Feed control paired with proper stitch length ensures consistent stitch density when backstitching reinforces seams on upholstery projects.

Accessories and Replacement Parts Availability

Access to reliable replacement parts separates machines that serve you for decades from those that become expensive paperweights.

OEM alternatives and refurbished parts expand your supply chains when authorized distributors face inventory management delays.

Professional sewing equipment reviews consistently highlight part sourcing as critical for sewing machine maintenance, so verify supplier stock before committing to any sewing machine selection for heavy upholstery work.

How to Sew Leather and Upholstery Successfully

Sewing leather and upholstery requires specific techniques that differ substantially from working with standard fabrics. Your success depends on understanding proper needle selection, thread weight, and machine adjustments before you begin any project.

The following sections cover the critical setup and technique factors that prevent material damage and guarantee professional-quality results.

Selecting The Right Needle Size and Type

Your sewing machine selection hinges on leather thickness and needle compatibility from the start. For 1.0 to 1.5 mm leather, begin with 90/14 or 100/16 needles.

Thicker hides between 2.0 to 3.0 mm demand 110/18 or 120/19 sizes. Diamond point needles penetrate cleanly, while reinforced needle material resists bending when sewing thick materials, ensuring stitch balance and needle durability throughout your project.

Thread Selection for Heavy Materials

Polyester and bonded nylon thread types deliver the tensile strength you need for leather upholstery and heavy duty applications.

Match thread thickness to material thickness and needle sizes—1.0 to 1.5 mm threads work with 110/18 to 125/19 needles when sewing thick materials.

Wax-coated finishes reduce friction during leather sewing, while proper stitch tension prevents breakage on your industrial sewing machine and maintains fabric strength.

Foot Pressure and Stitch Length Adjustment

Your stitch quality depends on the pressure-length interaction between the presser foot and feed dogs. Ideal settings prevent needle perforation while maintaining fabric feed control during leather sewing.

Balance these three elements for consistent results:

- Set foot pressure higher for thick hides to prevent slipping against feed dogs

- Adjust stitch length between 3.0-4.5 mm for dense materials without over-perforating

- Test sewing speed with sample pieces before committing to your project

Preventing Common Sewing Errors on Leather

Even proper foot pressure and stitch consistency settings can’t prevent errors if you overlook needle breakage and fabric shifting. Leather tension determines seam durability, while error prevention begins with matching your leather sewing machine’s capabilities to material thickness.

| Common Error | Prevention Strategy |

|---|---|

| Skipped stitches | Replace dull needles promptly |

| Fabric shifting | Use walking foot or non-slip mat |

| Thread breakage | Check tension and use polyester thread |

| Puckered seams | Reduce presser foot pressure |

Your leather sewing tips should prioritize needle inspection before sewing thick fabrics.

Working With Different Leather Thicknesses

Understanding leather thickness allows you to adapt sewing techniques and material selection for reliable results. Your stitch patterns and fabric handling methods must shift with hide weight.

- Under 2 oz hides require minimal presser foot pressure to prevent stretching

- 3 to 5 oz leather demands size 90/14 to 100/16 needles for consistent penetration

- 6 oz and above needs industrial-grade leather sewing machines with walking feet

- Thicker materials require longer stitch lengths to avoid bunching

- Heavy duty materials benefit from reduced sewing speed for control

Maintenance and Care for Leather Sewing Machines

Your leather sewing machine is a workhorse that demands consistent attention to perform at its peak. Proper maintenance prevents costly breakdowns and extends the life of your equipment by years.

Here’s what you need to build into your routine to keep your machine running strong through thousands of feet of heavy material.

Daily Cleaning and Lubrication Schedule

Your leather sewing machine demands consistent attention to perform reliably under heavy loads. After each session, brush lint and leather dust from the needle plate and feed dogs with a soft tool.

Apply machine oil to designated pivot points following the manufacturer’s maintenance schedules—usually every 20 to 40 hours of operation. Daily lubrication and cleaning routines prevent jamming and extend the lifespan of industrial sewing machines considerably.

Oil Checks for Smooth Operation

Regularly verify oil level between the dipstick’s min and max marks to prevent gear wear in your industrial sewing machine. Monitor for contaminants like metallic particles or milky residue that signal bearing failure.

Check viscosity to guarantee proper flow optimization during high sewing speed runs on thick leather. Confirm steady pressure through the sight glass during operation to maintain smooth gear meshing and consistent performance on leather sewing projects.

Needle Replacement and Inspection

Inspect your sewing machine needle under bright light before each leather upholstery project to spot bends, burrs, or heat discoloration that compromise stitch quality. Replace needles every six to eight hours of active leather sewing to prevent thread tension issues and needle damage from degrading your work.

- Change needles immediately after hitting hardware like zippers or snaps on thick leather pieces

- Run your fingertip down the shaft to detect rough spots invisible to the eye

- Match needle size to thread weight, pairing Tex 90 thread with size 18 leather needles

- Use 130/705 H LL leather-point needles for domestic machines and 135×16 for industrial sewing machines

- Test fresh needles on scrap material to confirm clean holes and balanced tension before starting seams

Troubleshooting Common Issues With Heavy Materials

When your machine stalls mid-seam or skips stitches on thick hides, diagnosis beats guesswork every time. Check motor overload first by reducing speed to 800 to 1,200 stitches per minute during continuous heavy-duty sewing needs. Adjust feed system pressure, verify needle breakage patterns, and match material thickness to machine capability using this quick reference:

| Issue | Probable Cause | Solution |

|---|---|---|

| Skipped stitches | Needle deflection on thick layers | Use size 100/16 or 110/18 leather needles |

| Uneven feed | Worn feed dogs or low foot pressure | Replace teeth, increase presser foot stroke |

| Thread breaks | Excessive tension or speed | Lower tension, reduce to mid-range speed |

| Motor stalls | Overloading beyond rated capacity | Reduce feed rate, allow cooling breaks |

| Puckered seams | Compressed leather from high pressure | Lengthen stitch, decrease foot pressure |

Test adjustments on scrap material before resuming production work to confirm stitch consistency and prevent costly errors on finished pieces.

Storage and Long-term Machine Care

When your industrial sewing machine equipment sits idle between heavy-duty sewing needs, protect it like the precision tool it is. Store it in a climate-controlled space with humidity below 50 percent, apply manufacturer-specified lubrication to all moving parts, and raise the unit on a shelf to prevent ground moisture exposure.

- Document your last oil check and cleaning date for easy reference during reactivation

- Cover with breathable fabric that blocks dust but allows moisture escape

- Schedule pre-operation inspections before returning to leather sewing work

- Replace needles and verify belt tension after extended storage periods

Frequently Asked Questions (FAQs)

What sewing machine is good for sewing leather?

You need a machine with at least 0 to 5 amps of motor power, a walking foot system for even fabric feed, and a metal frame to handle leather stitching without flexing under pressure.

What is the best sewing machine for leather & upholstery projects?

Like choosing between a scalpel and a sledgehammer, your best leather sewing machine depends on project scale—industrial models dominate heavy upholstery fabric types, while quality domestic units deliver excellent leather stitch quality for smaller jobs.

How do I choose a heavy-duty sewing machine for leather?

You’ll want at least 1,000 to 1,500 stitches per minute from a motor with variable speed control.

Look for cast iron frames, walking foot mechanisms, and needle capacity up to 135 for varying leather thickness.

Which sewing machine is best for leather?

A workhorse leather sewing machine delivers consistent needle penetration through dense hides with a heavy duty motor of at least 0 horsepower, reliable stitch quality, and precise sewing speed control for leather crafting and upholstery projects.

Which upholstery sewing machine should I buy?

Choose an industrial model with walking foot and compound feed for consistent fabric handling.

Motor efficiency above 5 horsepower ensures smooth operation through thick leather, while cast iron construction guarantees durability for heavy duty sewing needs.

Can a sewing machine sew through leather?

Yes, your sewing machine can sew leather—if it delivers adequate power and proper needle selection.

Lightweight garment leather works on sturdy domestic models, while thicker upholstery hides demand industrial-grade machines with walking feet.

Can a sewing machine sew upholstery?

Industrial sewing machines handle upholstery fabric with adequate power and walking foot mechanisms, while domestic heavy duty models manage lighter projects.

Heavy duty needs demand sturdy motors and specialized feed systems for consistent results through thick materials.

What thread tension is best for leather sewing?

Set your top thread tension higher than standard settings for thick leather to achieve proper stitch balance, testing on scrap material until the bobbin thread sits just below the top surface without visible looping.

How to avoid skipped stitches on heavy fabrics?

Prevent skipped stitches by ensuring proper needle-bobbin timing and adequate motor power at low speeds, using a walking foot or feed system to maintain even fabric flow, and reducing machine vibration through a rigid frame.

Can standard sewing machines handle upholstery projects?

Standard sewing machines can tackle light upholstery fabric choices, but motor capacity and needle durability limit leather upholstery projects.

Fabric thickness beyond two layers usually demands industrial sewing machines with enhanced sewing speed control and specialized feed systems.

Conclusion

Think of Goldilocks settling into that perfectly fitted chair—your workflow demands the same precision match. Detailed sewing machine reviews for leather and upholstery reveal that motor power, feed mechanisms, and presser foot adjustability separate machines that handle thick materials from those that merely claim to.

Your selection determines whether you’ll complete projects efficiently or fight mechanical limitations daily. Match your machine’s specifications to your material thickness requirements, and you’ll transform challenging upholstery work into consistent, professional results.