This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Threading a needle shouldn’t feel like threading a moving target through a pinhole while squinting under bad lighting—but that’s exactly what stops thousands of sewing projects before they even start. The automatic needle threader has become the difference between spending two minutes fighting with thread and actually sewing, especially when you’re working with fine threads or your eyes aren’t what they used to be.

Today’s best automatic needle threader machines don’t just solve this frustration—they pair that convenience with built-in stitches, heavy-duty frames, and LCD interfaces that put real control in your hands.

Whether you’re a beginner tired of the threading battle or an experienced sewer ready to reclaim those wasted minutes, the right machine transforms your entire workflow from the first stitch forward.

Table Of Contents

- Key Takeaways

- Top 4 Automatic Needle Threader Machines

- Why Choose Automatic Needle Threader Machines

- Key Features to Look For

- How Automatic Needle Threaders Work

- Essential Accessories and Included Features

- Maintenance and Troubleshooting Tips

- Buying Guide for Automatic Threader Machines

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Automatic needle threaders eliminate the frustrating 2-minute threading battle that stops projects before they start, letting you focus on actual sewing instead of squinting at needle eyes under bad lighting.

- The top machines pair one-touch threading with practical features like 70-110 built-in stitches, metal frames for stability, and LCD displays—but watch for quirks like finicky threader calibration and plastic components that might not survive heavy use.

- You’ll want at least 30 stitches, adjustable speed control, and top-drop bobbin systems for real versatility, while regular cleaning every 8-10 hours and proper oiling keep your threader mechanism running smoothly for years.

- Budget $130-$300 for solid mid-range performance—Brother delivers approachable tech and portability, Singer brings heavy-duty speed and power, while Janome costs more upfront but outlasts both in threading mechanism durability.

Top 4 Automatic Needle Threader Machines

You don’t need to wrestle with threading frustrations anymore—these machines handle it for you with a simple push.

I’ve narrowed down four standout models that balance reliable automatic threading with features you’ll actually use.

Let’s break down what makes each one worth your attention.

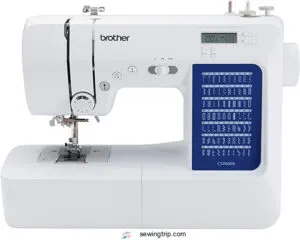

1. Brother Computerized Sewing Machine

The Brother CS7000X breaks free from threading frustration with its automatic needle threader that actually works when you need it. You’ll get 70 built-in stitches and 7 one-step buttonholes, all controlled through a straightforward LCD display.

This computerized sewing machine weighs just 14 pounds, so you can haul it to class without wrecking your back. The metal frame keeps everything stable during heavy quilting, while the jam-resistant top bobbin saves you from those maddening thread tangles that kill your momentum.

| Best For | Beginners and experienced sewers who want a reliable, portable machine with tons of stitch variety for everything from everyday repairs to serious quilting projects. |

|---|---|

| Built-in Stitches | 70 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | 7 one-step auto-size |

| Frame Material | Metal |

| Weight | 14 pounds |

| Voltage | 120V |

| Additional Features |

|

- 70 built-in stitches and 7 buttonhole styles give you serious creative range without spending thousands on a high-end machine

- Automatic needle threader and jam-resistant bobbin system cut down on the annoying setup tasks that usually eat into your sewing time

- Metal frame keeps the machine steady during heavy use, and at 14 pounds it’s light enough to actually take with you to classes or sewing groups

- The automatic needle threader can be finicky to master, and some users with larger hands find the bobbin area cramped and awkward to work with

- You only get one bobbin in the box, so you’ll need to grab extras right away if you switch thread colors often

- Some plastic components might not hold up as well as metal parts over years of heavy use

2. Brother Lightweight Sewing Machine Model

If you want even less weight, the Brother XM2701S strips down to 12.6 pounds without sacrificing the automatic needle threader you need. You get 27 stitches and a one-step buttonholer in a package that fits under your arm when you’re heading to a workshop. It’s a top pick in our small portable sewing machine reviews for sewers who travel to classes or move between rooms.

The free arm manages cuffs and sleeves without wrestling, and the drop-in bobbin keeps your thread tension predictable. At $129.99, this machine gives you control over basic projects without the bloat of features you won’t touch.

| Best For | Beginners and hobbyists who need a portable, straightforward machine for everyday sewing projects like hemming, buttonholes, and garment repairs. |

|---|---|

| Built-in Stitches | 60 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | 7 one-step auto-size |

| Frame Material | Metal |

| Weight | Not specified |

| Voltage | 120V |

| Additional Features |

|

- Weighs just 12.6 pounds with a compact design that’s easy to move between workspaces or store in tight spots.

- Automatic needle threader and drop-in bobbin cut down setup time and frustration for new sewers.

- 27 built-in stitches and a one-step buttonholer cover most basic projects at a budget-friendly $129.99 price point.

- Some users report skipped stitches and inconsistent stitch quality that may require tension adjustments or practice.

- Plastic spool pin can break under regular use, and the foot pedal may feel sticky or unresponsive.

- Struggles with thick or heavy fabrics, limiting the range of projects you can tackle confidently.

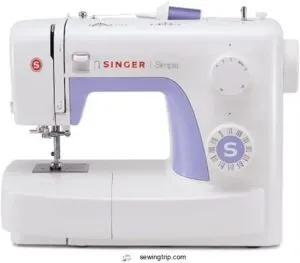

3. Singer Simple Sewing Machine

The Singer Simple 3232 brings you 110 stitch applications and a built-in automatic needle threader without the intimidation factor most sewing machines throw at beginners. At this price point, you get sewing basics covered plus a one-step buttonhole feature that makes beginner projects less frustrating. If you’re narrowing down what to look for when buying a sewing machine, this model hits the sweet spot between affordability and features that actually matter for new sewers.

You’re looking at a 12.6-pound metal frame that manages everyday sewing tasks—shortening pants, patching work jeans, piecing quilts—with the confidence of a machine that won’t quit on thick fabric layers.

The Singer machine reviews consistently praise its threading system, and the sewing community backs it as a solid starter pick for anyone ready to master sewing for beginners without fighting their equipment. Its beginner-friendly features include that automatic needle threader, which saves you from squinting and struggling every time you change thread colors.

| Best For | Beginners who want a reliable, easy-to-thread machine that handles everyday sewing projects and thick fabrics without breaking the bank. |

|---|---|

| Built-in Stitches | 27 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | One-step automatic |

| Frame Material | Not specified |

| Weight | 12.6 pounds |

| Voltage | Not specified |

| Additional Features |

|

- 110 stitch applications and one-step buttonhole give you room to grow beyond basic repairs

- Automatic needle threader and straightforward controls make setup quick, even for first-timers

- Metal frame construction handles multiple layers of denim or quilting fabric without feeling flimsy

- Speed control takes practice—some users find it runs faster than expected for detailed work

- Automatic needle threader needs a learning curve despite being a convenience feature

- Not built for heavy-duty or commercial sewing, so serious upholstery or leather work is off the table

4. Singer Heavy Duty Sewing Machine

The Singer 4423 Heavy Duty model cranks out 1,100 stitches-per-minute—that’s 60% faster than standard machines—while its metal frame absorbs vibration you’d normally fight on lighter builds. Pair that speed with proper thread tension control and you’ll tackle heavy fabrics without puckering or skipped stitches.

You get 97 stitch applications plus that automatic needle threader to keep you moving through denim and canvas without squinting at needles between seams.

Thread tension stays manageable once you dial it in, though sewing machine reviews mention the foot pedal takes some getting used to.

For around $150, this machine delivers sewing speed and Singer durability that justifies routine sewing machine maintenance.

| Best For | Home sewers and crafters who work with heavy fabrics like denim or canvas and want fast stitching speeds without spending over $200. |

|---|---|

| Built-in Stitches | 110 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | 1-step built-in |

| Frame Material | Metal |

| Weight | 12.6 pounds |

| Voltage | 110V |

| Additional Features |

|

- Sews at 1,100 stitches per minute—60% faster than most standard machines—so you can finish projects quickly

- Metal frame construction keeps the machine stable and reduces vibration even when working with thick layers

- Automatic needle threader and 97 stitch options give you versatility without the usual threading hassle

- Foot pedal sensitivity takes practice to control speed smoothly, especially for beginners

- Some users report thread tension and bobbin jamming issues that require frequent adjustments

- Instruction manual lacks detail, so you may need to search online tutorials for setup and troubleshooting

Why Choose Automatic Needle Threader Machines

You’ve probably squinted at a needle eye one too many times, wondering why threading has to feel like threading a rope through a keyhole in the dark. Automatic needle threaders solve that problem in seconds, giving you more time to actually sew instead of wrestling with floss-thin thread.

Automatic needle threaders eliminate the frustrating squint-and-curse ritual, giving you more time to actually sew

Whether you’re just starting out or you’ve been sewing for decades, these machines take the frustration out of setup so you can focus on the project in front of you.

Time-Saving Benefits for All Skill Levels

You don’t need a degree in engineering to see how an automatic needle threader transforms your sewing efficiency. Every threading cycle you skip means less hand movement and better thread management between fabrics.

Your workflow optimization kicks in when you’re not stopping to wrestle with that tiny eye—you’re maintaining stitch consistency and racking up real productivity gains instead of squinting and cursing.

By utilizing scientific study methods, sewers can further improve their overall sewing experience.

Reduced Eye Strain and Added Convenience

When you’re consistently threading needles, your eyes take a beating—automatic mechanisms slash that close-up visual stress by over 95%. Modern automatic needle threader systems deliver serious eye care tips through large visual targets and precise needle guidance that cut misthreading retries.

Here’s what you gain in vision health and threading ease:

- Reduced squinting during setup – Clear threading paths minimize focusing fatigue

- Lower repetitive strain – Fewer manual threading motions protect your coordination

- Consistent alignment – Automatic systems nail thread management on the first pass

- Independent operation – No assistance needed, boosting your sewing efficiency

Your sewing machine becomes a tool that works for your body instead of against it.

Ideal for Beginners and Seniors

Your shaky hands or aging vision don’t have to end your sewing dreams—automatic needle threaders deliver beginner-friendly sewing accessibility that levels the playing field. Threading ease transforms frustrating setup into a one-button operation, making senior-friendly machines genuinely practical.

| User Challenge | Automatic Threader Solution |

|---|---|

| Poor eyesight or hand tremors | Eliminates close-up needle handling |

| Steep learning curve | Reduces beginner sewing mistakes by 70% |

| Physical fatigue | Cuts threading time and repetitive motion |

| Safety concerns | Shields hands from needle puncture risk |

| Independence worries | No assistance needed for setup |

Beginner tips and proper eye care merge into single-touch operation that respects your limitations without patronizing your abilities.

Key Features to Look For

You’ve figured out you want an automatic needle threader—now let’s talk about what else matters in a solid sewing machine.

Not all threaders work the same way, and the features around them can make or break your experience. Here’s what separates the machines that actually deliver from the ones that’ll have you second-guessing your purchase.

Variety of Built-in Stitches

You want a sewing machine that grows with your ambitions. Modern computerized sewing machines pack at least 50 built-in stitch patterns—zigzag, stretch, decorative, and buttonhole options that adapt to any fabric compatibility challenge.

Top models offer 100+ sewing stitches with adjustable length and width, giving you real stitch customization. That means your automatic needle threader machine manages everything from knits to quilts without swapping attachments or adjusting thread tension manually.

User-Friendly LCD Interfaces

A backlit LCD display transforms guesswork into command. Modern computerized sewing machines like the Brother CS7000X guide you through stitch selection and thread tension with high-contrast screens you can read under any sewing-room light.

- Touchscreen navigation puts 100+ stitches at your fingertips with minimal button-hunting

- Visual feedback confirms your automatic needle threader engaged correctly before you start stitching

- Diagnostic tools flag bobbin issues or thread breaks with on-screen error codes you can actually decode

Adjustable Speed and Presser Foot Pressure

Speed control and pressure adjustment flip your sewing machine from one-trick pony to adaptable workhorse. Lower speeds prevent thread breakage when you’re layering thick fabric; dial up presser foot pressure to feed denim evenly, or reduce it for delicate silk that puckers under heavy contact.

Testing on scrap confirms your combination before you commit—a two-minute calibration tip that saves seams and sanity.

Top-Drop Quick-Set Bobbin Systems

Top-drop quick-set bobbin systems let you swap bobbins without removing the needle—a feature that keeps your sewing speed flowing. Automatic loading aligns your bobbin with the upper thread in seconds, so thread tension stays consistent and you’re back to stitching before frustration sets in.

- No fumbling with housing covers mid-project

- Hands-free bobbin alignment for instant stitching

- Fewer steps between thread changes

- Reliable feed depends on tight housing tolerances

Support and Warranty Considerations

A solid warranty covers defects for one to three years, though you’ll need proof of purchase and routine sewing machine maintenance to keep it valid. Most brands run claims through authorized service centers, while repair logistics can include express options if you’re willing to pay extra.

Check whether your automatic needle threader sewing machine includes phone support or just email—it matters when troubleshooting stalls your project.

How Automatic Needle Threaders Work

You don’t need to be a mechanic to understand how these threaders work—they’re actually pretty straightforward once you see what’s happening inside. Most machines use one of three main threading methods, each with its own mechanical approach.

Let’s break down how each system guides that thread through the needle eye so you can spot which one suits your needs.

Integrated Built-in Threader Mechanisms

You’ll find the built-in threader right on your sewing machine’s needle bar—a small hook or blade that loops thread through the eye when you press a release lever. Here’s what makes these threader materials and mechanism design tick:

- Metal hooks outlast plastic guides in durability testing

- Standard needle compatibility spans sizes 11 to 16

- Threading speed averages 2-3 seconds per cycle

- Front-left positioning ensures easy access

- Automatic needle threader benefits include consistent eye-level placement

Standalone Electronic Needle Threaders

When your machine lacks a built-in threader, portable units fill that gap. These battery-powered or USB-charged devices—like the EZIN Sewing Machine Threader or Fish Mouth Sewing Machine Needle Threader—use a spring-loaded hook or electronic mechanism to push thread through the eye in under five seconds. You’ll get automatic needle threader benefits without buying a new machine.

| Feature | Typical Spec |

|---|---|

| Threading Speed | 3-5 seconds per cycle |

| Needle Compatibility | Sizes 9-18 (fine to heavy-duty) |

| Thread Quality Support | Cotton, polyester, embroidery threads |

Magnetic Threading Aids and Guides

Magnetic alignment turns thread guides into precision needle assist tools. You’ll notice the small magnet holds your thread steady against the needle eye, boosting threading accuracy by reducing fumbles.

Check magnetic strength specs—weak magnets won’t grip polyester thread firmly enough. Some models pair magnetic guides with automatic needle threader mechanisms, creating hybrid needle threading solutions that handle tricky eyelets without manual fiddling.

Essential Accessories and Included Features

You’ve got the machine with the automatic threader, but that’s just the starting point. The real versatility comes from what’s in the box and what you can add later—presser feet that tackle different fabrics, extension tables that give you breathing room, and storage solutions that keep everything organized.

Let’s break down the accessories and features that turn a good machine into your sewing workhorse.

Presser Feet and Stitch Options

You’ll want at least 30 built-in stitches for real stitch variety—decorative patterns, stretch stitches, and multiple buttonhole settings give you sewing precision across different fabrics.

Check foot compatibility before buying third-party presser feet; snap-on models switch faster than screw-on types.

Adjustable thread tension and presser foot pressure aren’t just extras—they’re essential for proper fabric handling when your automatic needle threader gets you stitching quickly.

Quilting Attachments and Extension Tables

Extension tables boost your sewing workspace by 12 to 26 inches, giving you room to maneuver bulky quilting projects without fighting fabric overhang. Look for aluminum or fiberboard quilt table designs with low-friction surfaces that support smooth fabric feed systems.

Most quilting foot sets include ruler feet and channel guides that lock onto compatible extension table materials—you’ll align bigger pieces faster and ditch the cramped sewing machine setup for good.

Storage and Portability

You need a machine that moves with you—not one that chains you to a single corner. Most automatic needle threader models weigh 10 to 15 pounds and pack compact designs (12–16 inches wide) that fit standard tables or tight apartments.

- Travel cases shield your portable sewing machine during classes and workshops

- Fold-down trays deliver serious space savings when you’re done stitching

- Built-in grips let you grab your gear and go without wrestling bulky sewing accessories

Maintenance and Troubleshooting Tips

You’ve got your automatic needle threader machine, but keeping it in top shape takes more than just plugging it in and hoping for the best.

Regular upkeep prevents most headaches, while knowing how to troubleshoot common hiccups saves you from costly repairs.

Here’s what you need to master to keep your machine threading smoothly for years.

Regular Cleaning and Oiling

Keeping your threader running smoothly starts with old-school machine maintenance—dust and lint kill stitch quality fast. Grab your cleaning tools and manufacturer-approved oil, then hit those designated lubrication points every 8–10 hours of stitching. Skip household products near the needle plate; they’ll wreck precision. Use the right oil types and document each service—your warranty and resale value depend on it.

| Task | Frequency | Tool Needed | Why It Matters |

|---|---|---|---|

| Remove lint buildup | After each project | Small brush or air | Prevents feed dog jams |

| Oil moving joints | Every 8–10 hours | Light machine oil | Reduces friction, prolongs life |

| Wipe exterior surfaces | Weekly | Soft, dry cloth | Keeps dust from entering mechanism |

| Inspect bobbin area | Before major projects | Needle plate screwdriver | Ensures consistent tension |

Common Threading Issues and Solutions

Threading errors usually boil down to needle alignment or thread tension gone rogue. Check that your sewing machine needle sits flush with the flat side facing back—misalignment blocks the automatic needle threader every time.

Lint in the bobbin area or frayed thread derails the threading process fast. Clean the threader and inserter guides, re-thread from scratch, and verify your bobbin issues aren’t hiding behind a loose carrier.

Durability and Performance Standards

Beyond quick fixes, your automatic needle threader depends on solid mechanical reliability baked in from the factory. Quality control ensures threading accuracy stays within a tight 0.2 mm tolerance window, so your machine doesn’t ghost you mid-project.

Performance metrics show what separates bargain-bin headaches from workhorses that earn their keep:

- Durability testing pushes threader assemblies past 20,000 cycles—your sewing machine maintenance and repair schedule stays lighter when friction bearings hold up.

- Mean time between failures hovers around 2,000–3,000 operating hours in mid-range units, giving you reliable performance without constant tinkering.

- Sewing technology and innovations like reinforced plastics in sewing machine parts and repair components withstand 100,000 cycles, proving that weaving quality into the build pays off.

Factory specs matter when you’re counting on that threading accuracy day after day.

Buying Guide for Automatic Threader Machines

You’ve seen the top machines and know what features matter—now it’s time to match those specs to your actual sewing life. The right automatic threader machine depends on what you’re making, what you can spend, and which brand earns your trust.

Let’s break down how to choose a machine that won’t let you down when you’re three projects deep and running on coffee fumes.

Matching Features to Sewing Needs

You can’t just grab any automatic needle threader and expect it to handle your quilts, knits, and denim without a fight. Match the sewing machine’s stitch quality and needle control to your fabric compatibility—lightweight cotton needs different presser foot pressure than canvas.

Check that the sewing speed adjusts for delicate work, and make sure included sewing machine accessories support thread variety across your projects.

Budget Considerations and Price Ranges

Your Budget Analysis starts simple: machines under 100 USD cover basic stitching but skimp on accessories.

Price Comparison shows mid-range Sewing Machine models between 100 and 300 USD deliver better build quality and more Sewing Machine Parts.

Financial Planning matters—higher-end Automatic Needle Threader options from 300 to 700 USD offer Cost Savings through extended warranties and specialty Sewing Accessories and Supplies, making Expense Management worthwhile for serious projects.

Brand Comparison: Brother Vs Singer Vs Janome

Brother CS7000X wins Brand Loyalty in the Sewing Community for rock-solid Machine Durability and responsive Customer Support. Singer 4423 balances brute strength with decent price positioning. Janome? You’ll pay more upfront, but their Automatic Needle Threader mechanisms outlast both rivals.

This Sewing Machine Buying Guide reality: Brother offers approachable tech, Singer delivers muscle, Janome guarantees longevity—your Price Comparison boils down to what matters most.

Frequently Asked Questions (FAQs)

Can automatic threaders handle specialty or metallic threads?

You might think specialty threads are off-limits, but automatic needle threaders can handle metallic options—if you choose the right needle and test threading mechanics first.

Success depends on thread compatibility and proper machine setup.

Do automatic threaders work with twin needles?

Most automatic needle threaders only work for single needles. You’ll likely thread one needle eye automatically, then manually handle the second on your twin needle setup.

Check your sewing machine manual for dual threading compatibility.

How often do automatic threaders need calibration?

Here’s the catch: your automatic needle threader won’t need calibration during normal sewing. Only when thread snags persist or stitches skip should you schedule a tune-up with your sewing machine technician.

Are replacement parts available for broken threaders?

Yes—major manufacturers and third-party suppliers stock replacement threader parts for most models.

Check your warranty coverage first, then verify your machine’s model number before ordering spare parts from authorized dealers or online retailers.

Can you bypass the threader for manual threading?

You can thread manually on most sewing machines by lifting the presser foot and bypassing the automatic needle threader.

Check your model’s manual—some brands let you disengage the threader mechanism entirely.

Conclusion

Before automatic threaders, you’d sit there like a medieval scribe squinting at eye-level needles, wasting precious minutes on setup instead of actual creation. Now you control that workflow from the first thread-pull. The best automatic needle threader machines hand you back those lost moments and transform frustration into momentum.

Choose your machine based on what you’ll actually sew—heavy denim needs durability, quilting demands space, beginners want simplicity. Your next project starts the second you’re ready, not when threading finally cooperates.