This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A bobbin on a sewing machine is a small spool that holds the bottom thread, forming the foundation of your stitches. It’s essential for your sewing projects, coming in various materials like plastic or metal, and sizes to fit different machines. You’ll find bobbins can be either drop-in or front-loading, depending on your machine’s design. For Baby Lock machines, Class 15 bobbins are commonly used.

Threading and loading it correctly—whether using a bobbin winder or manually—is key to seamless sewing. By understanding how to select and manage your bobbin, you’ll make sure your projects look polished from both sides.

Delving further will provide deeper insights into optimizing your sewing experience.

Table Of Contents

Key Takeaways

- A bobbin is a small spool that holds the bottom thread in a sewing machine, forming the foundation of stitches.

- Bobbins come in various materials, sizes, and designs, such as drop-in or front-loading, and are essential for maintaining a polished look on both sides of your sewing projects.

- Class 15 bobbins are commonly used in Baby Lock machines, and it’s crucial to consult the sewing machine manual for the correct size and type of bobbin to ensure proper fit and function.

- Metal and plastic bobbins each have their advantages and disadvantages, with metal bobbins being more durable but susceptible to rust, and plastic bobbins being less prone to rust but not as robust.

Bobbin Basics

Bobbins are essential components of a sewing machine that hold the bottom thread for stitches. They come in various materials, including plastic and metal, and are available in different sizes to fit different machines.

Bobbin cases can be drop-in or front-loading, and Class 15 bobbins are commonly used in Baby Lock machines. To wind a bobbin, use a bobbin winder on your sewing machine or a portable winder. Always match the bobbin thread with the top thread and trim excess thread after winding.

When loading a bobbin, make sure it’s the correct size and inserted correctly. Keep extra bobbins on hand for convenience and consider pre-wound bobbins for added convenience.

Bobbin Function and Selection

Bobbins are essential components of a sewing machine that hold the bottom thread and form the base of stitches. They come in various sizes and materials, such as plastic or metal, and can be drop-in or front-loading.

For many Baby Lock machines, Class 15 bobbins are commonly used, which are approximately 11mm in height and fit most newer Brother and Baby Lock sewing and embroidery machines. When selecting bobbins, it’s vital to consult the sewing machine manual for the correct size and avoid generic options for proper fit.

Metal and plastic options are available, with metal bobbins sometimes being used in vintage machines.

Class 15 Bobbins for Baby Lock Machines

Class 15 bobbins are intended to fit most modern Brother and Baby Lock sewing and embroidery machines. These bobbins measure about 11mm in height and are compatible with a variety of thread weights.

To avoid compatibility issues, it’s highly advisable to check the sewing machine manual before buying and using class 15 bobbins.

Class 15 bobbins can be purchased in both plastic and metal options.

Metal Vs. Plastic Options

In selecting between metal and plastic bobbins for your sewing machine, there are various aspects to deliberate. Metal bobbins are frequently favored for their longevity and compatibility with antiquated machines, as they were commonly employed before the 1960s and 1970s. However, plastic bobbins have gained prominence in recent years due to their availability and compatibility with modern machines.

Durability is a pivotal element when selecting between metal and plastic bobbins. While metal bobbins are generally more robust, they’re also more susceptible to rust, which can impact the performance of your machine. Plastic bobbins, on the other hand, are less prone to rust and tend to last longer with proper usage.

Compatibility is another crucial consideration. If your sewing machine came equipped with plastic bobbins, it’s advisable to adhere to plastic bobbins to avoid damaging the bobbin case. Similarly, if your machine came with metal bobbins, using metal bobbins is recommended. It’s of utmost importance to consult your sewing machine manual for the correct size and type of bobbin to ensure a proper fit and function.

Availability is also a factor. Plastic bobbins are generally more widely available and can be acquired from the manufacturer or reputable brands. Metal bobbins may be more challenging to locate, especially for older machines, and may require sourcing from specialized suppliers or vintage machine dealers.

In terms of bobbin thread breakage or loosening, both metal and plastic bobbins can experience issues. However, plastic bobbins are less likely to break when used for their intended purpose, and they’re generally easier to rethread if necessary.

When determining between metal and plastic bobbins, deliberate the age of your sewing machine, its intended use, and your personal preference. Both options possess their advantages and disadvantages, so it’s essential to choose the right bobbin for your specific machine and sewing needs.

Bobbin Threading Process

To guarantee a seamless sewing experience, it’s essential to grasp the bobbin threading procedure. Start by utilizing your sewing machine’s bobbin winder or a portable bobbin winder to wrap the thread around the bobbin. Be certain to wrap the thread with a matching or complementary color to the top thread for optimal outcomes.

Using Bobbin Winder

Using a bobbin winder is an essential part of the sewing process, ensuring that your machine sews smoothly and evenly. Here are four key steps to follow when winding a bobbin:

- Thread Selection: Choose the correct thread for your project, considering factors like thread weight, visibility, and compatibility with your fabric and machine.

- Threading the Winder: Begin by threading the bobbin winder with the thread, starting from the spool and passing it through the tension discs. Make sure the thread is under proper tension to prevent loose or sloppy bobbins.

- Winding the Bobbin: Once the thread is properly situated between the tensioner discs, wind the bobbin in a clockwise direction, ensuring that the thread tension remains consistent. Keep winding until the bobbin is full.

- Threading the Machine: After winding the bobbin, thread the machine with the wound bobbin and the top thread. Make sure the thread is properly tensioned and the bobbin is loaded correctly to prevent any issues during sewing.

Matching Thread Colors

Matching thread colors is essential for seam quality and visibility in your sewing projects. Start by taking into account the bobbin weight and thread quality, which should ideally correspond to the top thread weight. Use high-quality thread that’s appropriate for your fabric type. For ease of use, consider pre-wound bobbins or thread packs.

When threading your machine, make sure the bobbin compartment is free from any debris and the bobbin is inserted properly. For drop-in bobbins, place the wound bobbin in the compartment with the thread going counterclockwise. For front loading bobbins, load the bobbin case with thread going clockwise and pull it through the opening at the top of the case.

Always match the thread type and tension to maintain seam quality.

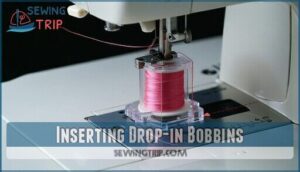

Inserting Drop-in Bobbins

To insert a drop-in bobbin, you need to remove the plastic cover from the bobbin compartment. Then, place the wound bobbin in the compartment with the thread going anti-clockwise. Pull the thread tail through the guide in the casing and thread the top thread of the machine. Lower and raise the needle to catch the bobbin thread.

Removing Plastic Cover

To remove the plastic cover on a sewing machine, follow these steps:

- Unplug your machine and remove the thread.

- Remove the needle from your machine.

- Remove the switch plate.

- Take a small brush or pick and clean out any visible lint in the bobbin case area.

Alternative cover materials include any thick, non-slippery fabric such as denim, wool, synthetic fleece, or knit fabric. These materials provide similar friction and control as felt pads.

Plastic covers are known for their durability, but they may become worn out or damaged over time. Regular maintenance, such as cleaning and removing lint, can help prolong the cover’s lifespan.

When troubleshooting a stuck cover, make sure that the bobbin area is clean and free of debris. Remove any lint or thread clippings that may have accumulated in the bobbin tray.

For maintenance tips, consider using a lint brush to clean the bobbin mechanism and surrounding area. Don’t wipe away any grease, as it’s needed for proper operation.

If you need to change the oil in your machine, follow the manufacturer’s recommendations and avoid lifting the machine to remove a bobbin, as this may expose the oil to foreign objects.

Remember to take good care of your sewing machine and perform regular maintenance to ensure it continues to function properly.

Placing Bobbin Correctly

To place a bobbin correctly, follow these steps:

- Remove the plastic cover from the bobbin compartment.

- Place the wound bobbin in the compartment with the thread anti-clockwise.

- Pull the thread tail through the guide in the casing.

- Thread the top thread of the machine.

- Lower and raise the needle to catch the bobbin thread.

Inserting Front Loading Bobbins

To insert a front loading bobbin, you’ll first need to open the bobbin compartment on your sewing machine. Next, remove the bobbin case from the machine, place the wound bobbin into the case with the thread feeding clockwise, pull the thread through the slot on top of the case, and load the case back into the machine.

Opening Bobbin Compartment

To open the bobbin compartment and insert a front-loading bobbin, follow these steps:

- Locate the bobbin compartment: On your sewing machine, find the area where the bobbin compartment is located. It’s typically hidden and requires the removal of the front extension table or an accessory compartment to access it.

- Remove the front extension table: If your machine has a front extension table, you’ll need to remove it to access the bobbin compartment.

- Open the front cover: Once the extension table is removed, open the front cover of the bobbin compartment.

- Access the bobbin area: Inside the bobbin compartment, you’ll see the bobbin area, which is usually hidden and requires the removal of the front extension table or an accessory compartment to access it.

- Insert the bobbin: With the bobbin area exposed, insert your bobbin into the bobbin case. Make sure the thread unwinds in the direction of the arrow, pulling the thread through the notches on the bobbin case.

- Position the bobbin case: Hold the bobbin case with the hinged latch towards you, and position it inside the shuttle opening with the long finger pointing upwards. Push the bobbin case, rotating it a little bit if necessary, until it snaps into place.

Remember to consult your sewing machine manual for specific instructions on opening the bobbin compartment and inserting a front-loading bobbin, as different machine models may have slightly different procedures.

Loading Bobbin Case

Loading the bobbin case in a sewing machine is a crucial part of the sewing process. There are two main types of bobbin cases: drop-in and front-loading. In a drop-in case, you merely drop the bobbin into the case and then push it into the machine. For front-loading cases, you need to physically thread the bobbin into the case before introducing it into the machine.

To load a front-loading bobbin case, follow these steps:

- Open the bobbin compartment: This is typically located on the side or front of the machine. Some machines may require you to remove a plastic cover or slide a lever to access the compartment.

- Remove the bobbin case: In some machines, the bobbin case is a separate piece that you can remove from the machine. In others, it may be built into the machine and not removable.

- Place the bobbin in the case: With the thread facing clockwise, insert the bobbin into the case. Be sure to follow the manufacturer’s instructions for your specific machine.

- Pull the thread through the slot: There should be a slot or hole in the top of the case where you can pull the thread through. This will verify that the bobbin thread is properly connected to the top thread.

- Load the bobbin case into the machine: Once the bobbin is in place, you can load the bobbin case back into the machine. This may involve pushing it into a slot or guiding it into a specific position.

- Thread the top thread: After loading the bobbin case, you’ll need to thread the top thread of the machine. This will guarantee that the top and bottom threads are properly connected.

- Lower and raise the needle: Finally, lower and raise the needle to catch the bobbin thread. This will verify that the machine is properly threaded and ready to sew.

Choosing Bobbin Thread

When selecting bobbin thread, you should match its weight to the weight of your top thread to guarantee balanced stitch formation. Additionally, consider the visibility of reverse sewing – using a bobbin thread that contrasts with your fabric may be desirable if you want your reverse stitches to be conspicuous.

Matching Thread Weight

When selecting thread for your bobbin, it’s important to consider the thread’s weight. The weight of the bobbin thread should correspond to the top thread to ensure optimal stitch quality. Pre-wound bobbins can simplify this process, as they’re pre-threaded with premium thread that’s compatible with the fabric you’re using.

Employing a spool pad can assist in maintaining appropriate thread tension and preventing uncontrolled spool spinning, which can impact the visibility of the reverse sewing. The proper thread friction is essential for a successful sewing project.

Visibility of Reverse Sewing

Regarding the visibility of reverse stitching, the selection of thread color plays a significant role in the success of your sewing endeavor. Here are some helpful suggestions:

-

Select a thread color contrasting with the fabric: This will enhance the visibility of the reverse stitching and ensure its seamless integration with the fabric.

-

Take into account the sheen of the bobbin thread: Threads with a high sheen may be less visible than matte threads, so consider this when making your thread choice.

-

Coordinate the thread color with the top thread: This will minimize the prominence of the reverse stitching, allowing it to blend harmoniously with the top thread.

-

Consider the fabric’s visibility: For darker fabrics, opt for a lighter thread color to guarantee the visibility of the reverse stitching.

Bobbin Troubleshooting

When facing bobbin issues on a sewing machine, you can troubleshoot in several ways. First, re-thread the machine to guarantee that the top thread operates smoothly. This can prevent the bobbin from jamming or creating irregular stitches.

Next, clear the bobbin area by removing any fluff or debris that may have gathered. This can help prevent thread breaks and enhance the machine’s overall operation.

Finally, verify that the bobbin is seated correctly in the bobbin case and that the tension is appropriate. If the bobbin isn’t inserted properly, it can cause thread breaks and missed starts.

Re-threading Machine

If your bobbin thread breaks, re-thread your machine. Check for tension issues, thread tangling, or needle damage. If lint is present in the bobbin case, clean it. Always insert the bobbin correctly and use the correct size. If your needle is dull, change it.

Cleaning Bobbin Case

Cleaning your bobbin case is an essential part of maintaining your sewing machine’s performance and preventing tension issues. To clean your bobbin case, follow these steps:

- Remove lint build-up: Regularly remove lint build-up to prevent debris from accumulating under the tension spring, which can affect your sewing machine’s tension.

- Use cleaning tools: Use a thin business card or a matchbook case to gently insert between the bobbin case and the tension spring to remove any debris. Avoid using metal tools as they can damage the bobbin case.

- Check the tension: After removing debris, check the tension to make certain it’s set correctly.

- Maintain regularly: Cleaning your bobbin case regularly helps prevent lint build-up and maintains consistent tension, leading to better sewing projects.

Remember to perform this maintenance every time you replace every 2nd bobbin to maintain the tension and prevent stitching issues. Additionally, consider oiling the bobbin case regularly to keep it in prime condition.

Frequently Asked Questions (FAQs)

What are the common causes of thread nesting in a sewing machine?

Thread nesting often stems from improper threading, incorrect bobbin placement, or tension issues. It’s like the machine’s having a bad hair day, tangling up when it should be smoothly stitching your masterpiece together.

How can I prevent my sewing machine from making a cracking or popping noise when I change the bobbin?

To prevent your sewing machine from making a cracking or popping noise when you change the bobbin, follow these steps:

- Clean the bobbin case: Remove the bobbin case from the machine and clean it thoroughly. Use a lint brush or an old makeup brush to remove any lint or dust that has accumulated inside. Wipe it down with a soft cloth and set it aside.

- Check for loose screws: Make sure that all the screws holding the bobbin case in place are tight. If any are loose, tighten them with a screwdriver.

- Properly insert the bobbin: When inserting the bobbin, make sure it’s placed correctly. For a drop-in bobbin, place it in the compartment with the thread anti-clockwise. For a front-loading bobbin, place it in the case with the thread clockwise and pull the thread through the slot in the top of the case.

- Use the correct size bobbin: Consult your sewing machine manual for the right size of bobbin for your machine. Using a bobbin that’s too small or too large can cause issues.

- Change the bobbin when needed: If your bobbin is running low on thread, change it to prevent any disruptions in your sewing.

- Check the needle: A dull needle can cause issues with your stitching. Make sure your needle is sharp and properly aligned.

What should I do if my top thread tension is too tight and the thread loops around the shuttle case, causing the bobbin to pop off?

If your top thread tension is too tight and the thread loops around the shuttle case, causing the bobbin to pop off, there are several steps you can take to resolve the problem:

- Check the bobbin case: Make sure the bobbin case is properly positioned and securely fastened in the machine. If it’s not, the bobbin may pop out.

- Clean the bobbin case: Lint or debris in the bobbin case can cause the bobbin to malfunction. Clean the case thoroughly to remove any obstructions.

- Thread the bobbin correctly: Make sure the bobbin is threaded correctly in the case, with the thread entering from the right side and exiting from the left.

- Use the correct bobbin size: Consult your sewing machine manual for the correct bobbin size and make sure you’re using the appropriate one.

- Adjust the tension: If the tension is too tight, lower the tension dial to loosen the thread. Test the stitching to see if the tension is now balanced.

- Change the needle: A dull needle can cause thread breakage and bobbin issues. Replace the needle with a new one.

How can I fix a bobbin winder that won’t spin on a computerized sewing machine?

To fix a bobbin winder that won’t spin on a computerized sewing machine, start by verifying you’re using the correct size bobbins and ensuring they’re correctly aligned with the spring on the bobbin winder shaft.

Check if the thread is passed through the bobbin winding guide correctly and investigate for scratches or defects on the bobbin.

If the thread is wound too tightly on the bobbin, unwind it to prevent it from sticking to the bobbin winder.

Finally, make sure the bobbin winder is engaged and that the thread isn’t wound too tightly on the bobbin.

What are some alternatives to spool pin felt pads for controlling spool spinning and preventing thread tangling?

Alternatives to spool pin felt pads include using any thick, non-slippery fabric such as denim, wool, synthetic fleece, or knit fabric. You can cut a spool-sized circle with a hole in the middle to provide similar friction and control. These alternatives can be made from mismatched socks or old sweatshirts.

Conclusion

Mastering the art of bobbin threading and loading on your sewing machine is akin to discovering the key to a flawlessly executed stitch. By comprehending the selection process of bobbins, whether it’s a Class 15 bobbin for Baby Lock machines or the decision between metal and plastic options, you’ll guarantee your projects are polished from both sides.

With the appropriate techniques, such as utilizing a bobbin winder and matching thread colors, you’ll be well on your way to effortless sewing. Remember the significance of problem-solving, from re-threading your machine to cleaning the bobbin case, to maintain ideal performance.