This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your home machine stalls on canvas. The thread snaps halfway through leather. You’re pushing fabric through manually because the feed dogs can’t grip heavyweight materials.

Commercial grade sewing machines eliminate these frustrations with 5,000–8,000 stitches per minute, cast-iron frames that absorb vibration, and motors built to run eight-hour shifts without overheating.

Garment manufacturers, upholstery shops, and automotive fabricators rely on these workhorses to maintain stitch consistency across multi-layer composites and heavy textiles that would damage standard equipment.

Understanding the features, capabilities, and maintenance requirements of industrial sewing equipment helps you select machines that match your production demands and deliver measurable returns on investment.

Table Of Contents

- Key Takeaways

- What is Commercial Grade Sewing?

- Main Types of Commercial Sewing Machines

- Essential Features of Industrial Sewing Machines

- Top 10 Commercial Grade Sewing Machines

- 1. Industrial Straight Stitch Sewing Machine

- 2. Juki Straight Stitch Sewing Machine

- 3. Janome High Speed Sewing Machine

- 4. Juki Industrial Sewing Machine

- 5. Juki Industrial Overlock Sewing Machine

- 6. Juki Portable Sewing Machine Quilter

- 7. Juki Computerized Sewing Machine

- 8. Lumina Serger Sewing Machine

- 9. Juki Industrial Straight Stitch Sewing Machine

- 10. Brother High Speed Sewing Machine

- Key Benefits of Commercial Grade Sewing

- Maintenance Tips for Commercial Sewing Equipment

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Commercial grade sewing machines deliver 5,000–8,000 stitches per minute with cast-iron frames and continuous-duty motors, eliminating the material handling failures and speed limitations that plague home equipment during heavyweight fabric production.

- Industrial machines cut production time 30–60% while maintaining stitch consistency within ±0.5mm across demanding runs, with specialized types like walking foot and overlock models handling specific tasks from leather upholstery to edge finishing at 1,500–3,000 SPM.

- Equipment investment pays for itself within 1–3 years through measurable gains including 25–40% labor cost reduction per unit, 15–30% energy savings with servo motors, and defect rates below 0.05% per thousand stitches when properly maintained.

- Regular maintenance schedules—needle replacement every 8 hours, lubrication every 4–8 hours, and professional servicing monthly for high-volume operations—extend machine lifespan to 10,000–15,000 operating hours while preventing costly production downtime.

What is Commercial Grade Sewing?

Commercial grade sewing represents a leap beyond home machines, built for the demands of production environments where speed, durability, and precision aren’t optional. These machines handle continuous operation across multiple shifts, working through heavy materials that would overwhelm domestic equipment.

Understanding what sets commercial grade apart—from its construction to its real-world applications—helps you choose equipment that matches your production goals.

Definition and Key Characteristics

Commercial grade sewing refers to equipment engineered for high-volume production environments, where speed, durability, and repeatable results define success. These industrial sewing machines generally operate at 5,000–8,000 stitches per minute, far exceeding home models.

Heavy duty features include cast-iron frames, continuous-duty motors rated from 300 to 1,500 watts, and reinforced fabric handling mechanisms. You’re investing in machines built for relentless performance across demanding industrial applications.

Understanding the dictionary subtopics can help in traversing complex sewing terminology.

Differences From Home Sewing

Home units can’t match the raw capability gap you’ll encounter in a sewing machine comparison. Industrial sewing machines deliver 30–60% faster cycle times in commercial production methods, maintaining stitch consistency within ±0.5% across demanding runs. Heavy-duty machines handle canvas, leather, and multi-layer composites that would stall domestic equipment.

Professional sewing techniques require:

- Continuous operation exceeding 15,000 runtime hours

- Industrial fabric handling with calibrated presser foot pressure

- Automated tension control for complex textiles

- Compliance with OSHA standards reducing facility injuries 20–40%.

Effective communication relies on theme identification techniques to convey information clearly.

Typical Applications in Industry

You’ll find industrial sewing machines powering garment production facilities that report 20–35% quality improvements with computerized patterning. Textile and garment manufacturing operations achieve 12–18% output gains on mass runs.

Automotive upholstery shops deploy sergers to cut seam defects 15–25%, while fabric handling systems in upholstery and leather sewing deliver 99% feed accuracy on challenging materials.

Medical fabrics producers maintain 0.5–1.0 mm stitch tolerance across multiple layers.

Main Types of Commercial Sewing Machines

Commercial sewing machines aren’t one-size-fits-all—you’ll find specialized equipment designed for specific tasks and production environments. Each machine type manages different fabric weights, stitch requirements, and workflow demands.

Here’s what you need to know about the four main categories that power professional sewing operations.

Industrial Straight Stitch Machines

You’ll find straight stitch machines are the workhorses behind mass production. Brands like Juki Industrials deliver stitch speeds up to 8,000 SPM with servo motor types that keep operations quiet and energy-efficient.

These industrial sewing machines lock in precision through rigid frames and sturdy fabric feed systems, ensuring machine durability even after 15,000 runtime hours. That consistency transforms your commercial sewing operation.

Overlock and Serger Machines

Edge finishing demands speed and precision in your production line. Industrial overlock and serger machines handle fabric edge control at 1,500–3,000 SPM, trimming and seaming in one pass.

Differential feed prevents puckering on knits, while adjustable loopers manage serger thread tension across multiple weights.

Blade guards and knife protection align with machine safety standards, and choosing the right commercial sewing equipment and sewing machine accessories and supplies keeps your overlock stitches razor-sharp shift after shift.

Walking Foot and Heavy Duty Machines

Heavy-duty sewing machines handle leather, canvas, and upholstery with ease, even when standard machines fail. Walking foot machines ensure multiple layers remain aligned, delivering precise flat-fell and topstitch results.

Your industrial upholstery shop requires the power to handle thick fabrics:

- Motor strength: 1/2 to 1 horsepower drives penetration through dense textiles

- Feed control: Reinforced feed dogs maintain tension on bulky panels

- Frame stability: Vibration-damping construction sustains long-hour operation

Commercial sewing machines built for demanding materials consistently deliver results, shift after shift.

Specialty and Computerized Machines

Computerized stitching transforms production runs with 20–60 programmable stitch patterns, enabling rapid changeovers for smart fabrication. Automated sewing features—thread trimming, needle positioning, precision cutting—boost efficiency in sophisticated embroidery and complex garment construction.

When selecting industrial or commercial sewing machines, consider networking capability that integrates with production management systems. Heavy-duty machines with jet-tension controls handle delicate and dense fabrics equally well, ensuring consistent results across shifts.

Essential Features of Industrial Sewing Machines

When you’re shopping for an industrial sewing machine, you need to know what separates a commercial workhorse from a basic home model. The right features determine whether your machine can handle continuous production runs or struggle through a single shift.

Let’s break down the essential capabilities that define true commercial-grade performance.

Motor Power and Stitch Speed

Motor strength and stitch speed define your machine’s production ceiling. Industrial motors rated between 550 and 2,200 watts enable stitches per minute from 3,000 to 5,000 SPM on straight-stitch models, while heavy-duty machines balance torque management with speed control to handle thick fabrics without skipping.

Servo motors improve motor efficiency and power consumption, giving you:

- Programmable sewing speeds for repeatable batch performance

- Precise speed control on knit and specialty materials

- Consistent sewing control during seam transitions

- Lower energy costs through optimized torque delivery

- Extended runtime between service intervals

Durability and Build Quality

Cast iron beds and alloy frames deliver frame stability that keeps your machine aligned through millions of cycles. Material selection drives wear resistance—corrosion-resistant coatings extend working surfaces by 40% in humid shops, while vibration testing proves isolation kits cut component wear by 24%. Heavy-duty machines and industrial sewing machines achieve component lifespans exceeding 15,000 runtime hours, minimizing sewing machine maintenance and repair downtime.

| Build Element | Performance Metric | Industry Standard |

|---|---|---|

| Cast Iron Bed Plates | Stitch Consistency Gain | 12% improvement at max speed |

| Alloy Frames | Flex Reduction Under Load | 38% vs. aluminum frames |

| Gear Trains | Service Life | 15–20 million cycles |

Fabric Handling Capabilities

You need precise material compatibility when production demands shift from silk to canvas mid-run. Feed systems with differential timing keep stitch consistency within ±0.5% across fabric families, while 72.5% of commercial lines rely on specialized presser feet to control mid-to-heavyweight industrial fabric.

Walking foot machines eliminate slippage on layered denim, and adjustable tension systems manage thread management across synthetics and wovens without recalibration delays.

Available Accessories and Attachments

Your machine’s core capabilities expand when you pair it with the right accessories. Presser feet for piping, hemming, and binding deliver precise results on varied materials, while pneumatic lifts reduce operator fatigue by 35%. Walking foot attachments and adjustable sewing guides maintain seam consistency across production runs.

- Teflon-coated presser foot gliding over vinyl upholstery at high speed

- Automatic thread cutters slicing cleanly between garment panels

- Computerized modules storing 100 stitch programs on a memory card

Top 10 Commercial Grade Sewing Machines

Choosing the right commercial sewing machine can transform your production capacity and stitch quality overnight. You’ll find machines built for everything from basic straight stitching to complex overlocking and heavy-duty upholstery work.

Here are ten commercial-grade options that deliver the speed, precision, and durability your operation demands.

1. Industrial Straight Stitch Sewing Machine

When you’re ready to conquer high-volume production, an industrial straight stitch sewing machine delivers the power and precision you need. These heavy-duty machines from brands like Juki Industrials achieve sewing speeds exceeding 5,000 stitches per minute while maintaining perfect stitch formation across multiple fabric thickness ranges.

Unlike walking foot machines designed for specialized tasks, straight stitch units focus on speed and machine durability—built with solid metal frames that withstand continuous operation.

Your industrial sewing machine selection starts here, where reliable performance meets demanding production schedules.

| Best For | Tailors, alteration shops, and small to mid-size manufacturers who need fast, consistent stitching on light to medium-weight fabrics without the complexity of multi-function machines. |

|---|---|

| Max Speed | 5500 spm |

| Weight | 150 lbs |

| Stitch Type | Straight stitch |

| Material | Cast Iron |

| Voltage | 110V |

| Brand | JUKI |

| Additional Features |

|

- Blazing speed of 5,500 stitches per minute cuts production time significantly while maintaining clean, uniform seams

- Reduced vibration and noise make long sewing sessions more comfortable compared to older industrial models

- Complete setup with table, stand, motor, and lighting means you’re ready to work right out of the box

- Not built for heavy materials like leather or thick canvas, limiting versatility for certain projects

- Assembly can be frustrating due to minimal instructions, and customer support from the seller may not be reliable if issues arise

- Expect minor cosmetic blemishes on the table and legs, plus some motor noise typical of industrial clutch systems

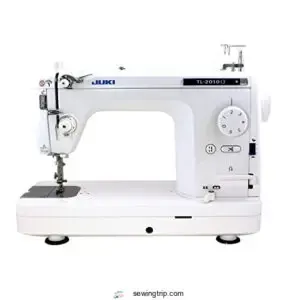

2. Juki Straight Stitch Sewing Machine

Your next advancement in stitch quality and sewing speed begins with Juki Industrials’ proven lineup. The Juki DDL8700 reaches 5,500 stitches per minute with outstanding fabric handling across garment production, while the Juki TL2000Qi offers portable power at 1,500 stitches per minute—perfect when you need flexibility without sacrificing machine durability.

Both models keep maintenance costs predictable through straightforward lubrication schedules and reliable construction.

For specialized edging work, the Juki MO6814S overlock complements your industrial sewing machines arsenal, delivering consistent performance that scales with your ambitions.

| Best For | Quilters and sewers who need a fast, reliable straight stitch machine for heavy-duty projects like home décor, thick fabrics, and multi-layer work. |

|---|---|

| Max Speed | 1500 spm |

| Weight | 25.4 lbs |

| Stitch Type | Straight stitch |

| Material | Aluminum die cast |

| Voltage | 110V |

| Brand | Not specified |

| Additional Features |

|

- Speeds up to 1,500 stitches per minute with low vibration thanks to the aluminum die cast construction, making it great for long quilting sessions

- Comes with an extension table for a wider work area and handles thick materials like denim and leather without struggling

- One-pedal operation and automatic needle threader make it easy to use right out of the box

- Only does straight stitches, so you’ll need a different machine if your projects require decorative or zigzag stitches

- Some users report the needle threader can be finicky and doesn’t always work as expected

- At 25.4 pounds, it’s pretty heavy and awkward to move around your sewing space

3. Janome High Speed Sewing Machine

Janome’s 1600PQC bridges home and industrial sewing machines with 1,600 stitches per minute and an automatic thread cutter that sharpens your thread management efficiency. You’ll appreciate the speed control slider and adjustable knee lift when precision meets pace on heavy-duty machine tasks.

This 40-pound unit manages multiple fabric layers with industrial pretension threading, though you should note the needle up/down stays active and bobbin access requires patience.

It’s built for teaching environments and serious quilters who demand sewing accuracy without compromising machine durability in commercial sewing applications.

| Best For | Quilters and heavy-duty sewers who need industrial-level speed and precision for piecing projects or working through thick fabric layers at home. |

|---|---|

| Max Speed | 1600 spm |

| Weight | 40 lbs |

| Stitch Type | Straight stitch |

| Material | Metal |

| Voltage | Not specified |

| Brand | Janome |

| Additional Features |

|

- Blazing 1,600 stitches per minute with automatic thread cutter saves time on repetitive seams and long quilting runs

- Industrial pretension threading and built-in needle threader reduce setup frustration and keep you sewing longer

- Adjustable knee lift and speed control slider give you hands-free fabric handling and exact pace control for tricky sections

- Needle up/down position stays locked on with no off switch, which might throw off your usual workflow

- Bobbin access feels clunky and thread runs out faster than expected during big projects

- Machine gets picky about thread and needle combos, and customer support doesn’t always respond quickly when issues pop up

4. Juki Industrial Sewing Machine

The Juki DU-1181N walks thick layers through at 2,000 stitches per minute with top and bottom feed technology that manages bag making and upholstery like a precision instrument. You’ll command heavy-duty stitching with industrial fabric handling that rivals machines twice the price, while the servo motor keeps your workspace quiet enough for in-home commercial sewing safety.

This cast iron workhorse from Juki delivers industrial sewing machine reliability with walking foot control that medium-weight fabrics demand, though you’ll need YouTube tutorials since written manuals aren’t included with heavy-duty machines of this caliber.

| Best For | Sewers tackling bag making, upholstery, or thick fabric projects who need industrial speed and power but want quiet operation for home-based work. |

|---|---|

| Max Speed | 2000 spm |

| Weight | ~100+ lbs |

| Stitch Type | Straight stitch |

| Material | Cast Iron |

| Voltage | 110V |

| Brand | JUKI |

| Additional Features |

|

- Handles medium to heavy fabrics with dual feed technology that prevents slipping and puckering on multi-layer projects

- Servo motor runs whisper-quiet at 2,000 stitches per minute, making it practical for residential spaces unlike loud clutch motors

- Cast iron construction delivers stability and longevity you’d expect from commercial equipment at this price point

- No written manual included—you’ll rely on YouTube videos and online forums to learn setup and troubleshooting

- Arrives as industrial equipment with cosmetic blemishes on the table and legs, not showroom-perfect

- Heavy weight and large footprint (48″ x 20″ x 48″) requires dedicated space and careful moving

5. Juki Industrial Overlock Sewing Machine

Professional seam finishing meets sewing automation in the Juki MO-68174S, a 4-thread industrial overlock that transforms garment edges at speeds exceeding 1,000 stitches per minute. You’ll master overlock applications from lightweight knits to industrial fabrics with differential feed ranging 0.6 to 2.0, while the included K.D table and servo motor deliver commercial sewing solutions that rival the Juki TL2010Q for value.

This machine upgrades your sewing techniques with trim-while-stitching efficiency, though assembly challenges may require professional setup to realize its heavy-duty machine potential in industrial sewing machine applications.

| Best For | Professional seamstresses and garment manufacturers who need high-speed seam finishing for light to heavy fabrics and can handle initial setup challenges. |

|---|---|

| Max Speed | Not specified |

| Weight | 150 lbs |

| Stitch Type | 4-thread overlock |

| Material | Not specified |

| Voltage | Not specified |

| Brand | JUKI |

| Additional Features |

|

- Blazing fast stitching at over 1,000 stitches per minute with precise differential feed (0.6–2.0) for both stretch and woven fabrics

- Trims and stitches in one pass, cutting finishing time in half compared to traditional methods

- Includes table and servo motor setup for immediate professional-grade operation

- Assembly is notoriously difficult and time-consuming, often requiring paid professional setup

- Instructions can be incomplete or missing, leaving you to figure things out on your own

- Quality control issues pop up—missing parts, incorrect packaging, and inconsistent customer service responses

6. Juki Portable Sewing Machine Quilter

You’ll bridge hobbyist quilting machines and industrial sewing machines with the Juki TL2010Q, a portable quilting powerhouse that delivers 900–1,200 stitches per minute in a travel-ready 15–25 pound package. Its aluminum frame and metal gears handle mid-weight fabrics across patchwork and free-motion quilting, while built-in lighting and walking foot compatibility improve your fabric handling.

Sewing accessories include presser feet and a carrying case, though quilter maintenance demands attention to tension settings. Machine portability meets commercial-grade stitching in quilting machine reviews praising its Juki HZLLB5020 build quality for portable quilting applications.

| Best For | Hobby quilters and small studio sewers who need a portable machine that can handle multiple fabric layers and deliver consistent straight stitching at higher speeds than basic domestic models. |

|---|---|

| Max Speed | Not specified |

| Weight | Not specified |

| Stitch Type | Straight stitch |

| Material | Not specified |

| Voltage | Not specified |

| Brand | JUKI |

| Additional Features |

|

- Delivers 900–1,200 stitches per minute with metal gears and an aluminum frame that balances durability with portability at 15–25 pounds

- Includes automatic thread trimming, knee lifter, and automatic needle threader that speed up quilting workflows

- Handles light to heavyweight materials with walking foot compatibility and adjustable presser foot pressure for even fabric feeding

- No dedicated scant 1/4″ foot included, requiring additional purchase or manual adjustment to achieve accurate piecing seams

- Built-in lighting may be insufficient for detailed work, often needing an external light source

- Thread tension requires fine-tuning when working with thick fabric layers or specialty materials like vinyl

7. Juki Computerized Sewing Machine

Computerized controls transform your production floor when you automate stitch sequencing on the Juki HZLLB5020, the machine upgrade that stores up to 100 programmable patterns for batch runs. Sewing automation reduces changeover time while Juki features like servo motors and automated tension sensors maintain ±0.05 variance across fabric types.

Heavy-duty sewing machines with computerized controls appear in industrial sewing machine reviews praising commercial sewing efficiency. Your sewing machine buying guide should weigh firmware updates and Juki accessories that expand your automated workflow.

| Best For | Sewists who need computerized precision and programmable patterns for batch production or repetitive tasks, from home business owners to small-scale commercial operations. |

|---|---|

| Max Speed | Not specified |

| Weight | 18.1 lbs |

| Stitch Type | 20 patterns |

| Material | Aluminum |

| Voltage | Not specified |

| Brand | JUKI |

| Additional Features |

|

- 20 built-in stitch patterns with LCD screen make pattern selection straightforward, while the auto needle threader and one-step buttonhole save setup time

- Sturdy aluminum construction and 7-point feed dog system handle multiple fabric layers smoothly, making it suitable for quilting and heavier materials

- Drop-in bobbin, free arm capability, and adjustable speed give you flexibility for different projects without fighting the machine

- Quality control issues reported by some users, including problems with backstitching and occasional defective units that require costly repairs

- Instruction manual is essential for troubleshooting, so you’ll need to spend time learning the system before tackling complex projects

- At 18 pounds it’s portable but not lightweight, and the accessory arm placement could be more user-friendly for frequent adjustments

8. Lumina Serger Sewing Machine

Thread tension challenges disappear when you load the Lumina Sienna Serger with its color-coded threading system. This semi-industrial serger machine delivers 1,300–1,600 stitches per minute across 2-, 3-, or 4-thread configurations.

Fabric handling improves with differential feed settings from 0.6 to 2.0, while the metal frame construction ensures machine durability through 5,000+ needle penetrations per minute.

Industrial sewing machine reviews spotlight this model in every sewing machine buying guide for heavy-duty sewing machines. Serging precision and sewing speed are maintained with oiling every 8–12 hours, as required for serger maintenance.

| Best For | Home sewers and small production shops looking for a reliable serger that handles heavy-duty projects with professional-quality edge finishing and fast stitching speeds. |

|---|---|

| Max Speed | Not specified |

| Weight | 17.6 lbs |

| Stitch Type | 3-4 thread serger |

| Material | Metal |

| Voltage | Not specified |

| Brand | Lumina |

| Additional Features |

|

- Color-coded threading system and optional air threading features cut setup time significantly, making the machine accessible even for beginners

- Differential feed from 0.6 to 2.0 prevents wavy edges on stretch fabrics while the adjustable stitch width (3-7 mm) handles everything from delicate rolled hems to thick seam finishes

- Metal frame construction and industrial-grade components deliver consistent performance at 1,300-1,600 stitches per minute, reducing project time by up to 95%

- No slower speed setting on the foot pedal makes precise control difficult for beginners who aren’t used to high-speed serging

- Confusing manual instructions about oiling schedules and maintenance procedures, plus email-only customer support can leave users stuck when problems arise

- Some users report durability and performance issues despite the industrial-grade marketing, suggesting quality control inconsistencies

9. Juki Industrial Straight Stitch Sewing Machine

Your Juki DDL-8700H blasts through 5,500 stitches per minute on medium to heavy fabric—ideal when you’re pushing production deadlines. The 11-inch arm space lets you maneuver quilts or garment pieces without cramping your workflow, while thread tension stability stays within ±0.5% across continuous runs.

This heavy-duty sewing machine manages multiple leather layers and denim with drop-feed precision. You’ll see industrial stitch consistency that meets OSHA-compliant standards.

Regular lubrication every 8–12 hours keeps sewing speed and needle performance locked in for 10,000+ runtime hours.

| Best For | Sewers tackling heavy fabrics like leather or denim who need industrial speed and reliability for high-volume projects or small production runs. |

|---|---|

| Max Speed | 5500 spm |

| Weight | 15 lbs |

| Stitch Type | Straight stitch |

| Material | Plastic/Stainless Steel |

| Voltage | Not specified |

| Brand | JUKI |

| Additional Features |

|

- Rips through 5,500 stitches per minute, cutting your project time significantly compared to home machines

- 11-inch arm space gives you room to work on quilts and larger pieces without fighting the machine

- Built for the long haul with industrial-grade construction that can handle 10,000 hours when maintained properly

- Assembly can be tricky since printed instructions aren’t included—you’ll need to hunt down online videos

- Some customers report missing hardware like bolts or the thread disc assembly right out of the box

- Table quality feels cheap with flimsy under-table trays and occasional shipping damage to edges

10. Brother High Speed Sewing Machine

Brother’s PQ1600S pumps out 1,500 stitches per minute, giving you a solid bridge between home quilting and commercial sewing. The 11.1-inch workspace and knee lifter handle heavy-duty sewing projects—think multiple denim layers or thick seams—without jamming your fabric handling.

You’ll appreciate the push-button thread cutter and adjustable feed dogs when speed optimization matters.

Regular maintenance tips include lubrication every 40 hours to keep this industrial sewing workhorse running. It’s a practical choice for serious hobbyists eyeing machine comparison before full factory investment.

| Best For | Quilters and serious hobbyists who need industrial-level speed and workspace for large projects but aren’t ready to invest in full commercial equipment. |

|---|---|

| Max Speed | 1500 spm |

| Weight | 24 lbs |

| Stitch Type | Straight stitch |

| Material | Not specified |

| Voltage | 120V |

| Brand | Brother |

| Additional Features |

|

- Blazing 1,500 stitches per minute gets you through projects fast without sacrificing stitch quality on heavy fabrics

- Extra-large 11.1″ x 23.3″ workspace plus knee lifter gives you real room to maneuver bulky quilts and thick layers

- Push-button thread cutter and color-coded feed dog adjustments make workflow smoother when you’re switching between different fabrics

- Side-loading bobbin won’t alert you when thread runs out, so you might not catch it until you’ve already stitched a section

- Top thread tension dial sits in an awkward spot that’s hard to see and adjust on the fly

- Pin feed mechanism and overall machine can develop squeaks or mechanical issues after heavy use, requiring maintenance every 40 hours

Key Benefits of Commercial Grade Sewing

Investing in commercial grade sewing equipment transforms your operation from grinding through projects to hitting production targets with confidence. These machines deliver measurable advantages that directly impact your bottom line, from cutting production time to maintaining consistent quality across thousands of units.

Commercial-grade sewing equipment transforms production operations by delivering measurable gains in speed, quality, and efficiency that directly impact your bottom line

Let’s break down the four core benefits that make commercial sewing machines worth the investment.

Increased Productivity and Efficiency

When you automate fabric feeding and leverage servo-controlled motors in your industrial sewing setup, you’ll cut handling time by 25–40% and boost single-operator efficiency by up to 35%. These heavy-duty sewing machines deliver workflow streamlining that transforms production optimization.

Commercial sewing operations see real efficiency metrics—reduced stoppages, lower energy costs, and automation benefits that keep your line moving without the constant manual threading or material repositioning.

Precision and Stitch Consistency

Speed isn’t everything—accuracy separates pros from hobbyists. Industrial sewing machines keep stitch length within ±0.2 mm and maintain thread tension stability across hours of continuous runs. You’ll see needle alignment hold ±0.05 mm tolerances, while servo motor control delivers closed-loop feedback that locks speeds within 1.5% of your setpoint. That precision transforms fabric feed reliability and slashes defect rates below 0.05% per thousand stitches.

- Optical sensors catch irregularities with 99% detection accuracy in real time

- Feed dog synchronization minimizes positional lag to less than 0.03 mm

- Heavy duty sewing machines cut material delamination risk by 72% on thick fabrics

Versatility Across Fabrics and Projects

From sheer silk to 6 mm canvas, industrial sewing machines handle fabric variety that would stall a home unit. Walking-foot designs cut needle breakage 25% on leather and denim, while overlock machines trim edge-finishing time 40–60% on knits.

You’ll switch between woven, spandex blends, and pile fabrics in a single production line—89% of commercial sewists do—with stitch consistency holding within ±0.2 mm across material handling challenges.

Cost Savings in Commercial Settings

Your capital expenditure pays for itself within 1–3 years when production efficiency climbs and labor costs drop 25–40% per unit. Industrial sewing supplies and heavy-duty sewing machines deliver measurable returns across textile manufacturing equipment operations:

- Energy savings cut electricity use 15–30% per hour with servo motors

- Material waste shrinks 1–5% through precise stitch control

- Sewing machine maintenance costs fall 10–25% annually with longer service intervals

Commercial sewing operations track these gains quarter over quarter.

Maintenance Tips for Commercial Sewing Equipment

Your commercial sewing machine is a workhorse, but even the toughest equipment won’t run forever without proper care. Regular maintenance keeps your operation running smoothly and prevents costly downtime that can derail production schedules.

Here are the essential maintenance practices every commercial sewing operation should follow.

Regular Cleaning and Lubrication

Your industrial machine performs best when you treat regular cleaning and lubrication as non-negotiable steps in your maintenance checklists. Daily dust removal methods prevent lint buildup that slashes stitch consistency, while lubrication intervals matched to your machine’s runtime—usually every 4–8 hours—keep heavy-duty sewing machines running smoothly.

Choose approved machine oil types for your sewing machine parts to avoid gumming, and follow cleaning schedules that align with your fabric workload.

Needle and Thread Replacement

Thread breakage and needle wear silently sabotage stitch quality if you skip replacement schedules. Swap needles every 8 hours of continuous operation on heavy-duty sewing machines to cut mis-stitches by 22%, and match thread types to fabric compatibility—polyester core-spun threads reduce breakage by 35% on high-torque models.

Track these sewing machine parts monthly, and you’ll see defect rates drop up to 25%.

Tension and Stitch Adjustment

Misaligned thread tension turns perfect seams into defect nightmares—your bottom line depends on getting it right. Tension consistency within ±0.5 g keeps stitch formation locked in across fabric types, while servo control systems reduce operator-induced drift by 25–40%.

- Calibrate thread tension every shift or material change to prevent bird-nesting and skipped stitches

- Adjust stitch length and presser foot pressure together—excessive pressure spikes defects by 15%

- Match differential feed ratios (0.9:1.0 to 1.25:1.0) to fabric stretch for knits and wovens

- Use digital tension meters with industrial sewing machines for 30–50% faster setup convergence

- Document needle calibration and sewing machine accessories settings per batch for repeatable quality

Scheduling Professional Servicing

Your machine’s runtime dictates when professional servicing intervals should occur—high-volume facilities require monthly preventive checks, while moderate use calls for visits every 6 to 12 months.

Service contracts with 24-hour response times protect production scheduling against unexpected downtime optimization failures.

Coordinate maintenance scheduling during off-peak hours to preserve output, and document every session to validate warranties while extending sewing machine features performance by 15,000+ hours.

Frequently Asked Questions (FAQs)

What safety training do industrial sewing operators need?

Operators need hands-on training in machine guarding, lockout procedures, and ergonomic practices—usually four hours per machine type.

Annual refreshers covering hazard communication and proper maintenance keep your team safe and productive in high-speed environments.

How much floor space do commercial machines require?

Industrial sewing equipment usually demands 60–80 square feet per station, including operator workspace and material flow zones.

Heavy duty machines with walking foot attachments may require additional clearance for safe fabric handling and ergonomic design.

Can commercial machines handle leather and vinyl materials?

Yes, with the right setup. Walking-foot machines handle leather and vinyl up to 1/4 inch thick when you pair them with heavy-duty needles and proper thread, ensuring consistent stitch quality across demanding materials.

Whats the average lifespan of industrial sewing equipment?

You can expect 10,000–15,000 operating hours from well-maintained industrial sewing gear. Heavy duty sewing machines benefit from sewing machine maintenance every 1,000–2,000 hours, greatly extending equipment durability and industrial sewing lifespan.

Conclusion

What separates a business that scales from one that stalls? The right equipment. Commercial grade sewing transforms your operation from manual struggle into efficient production.

Your investment in industrial machines—with their peerless speed, durability, and fabric versatility—pays dividends through consistent output and reduced downtime.

Match your machine to your materials, maintain it religiously, and you’ll handle contracts that once seemed impossible. Your capacity grows. Your reputation strengthens. Your bottom line reflects the difference.