This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Looking for the best sewing machine for shoes? You’re not alone! Crafting footwear requires a tough machine that can handle thick leather and multiple layers.

Looking for the best sewing machine for shoes? You’re not alone! Crafting footwear requires a tough machine that can handle thick leather and multiple layers.

The Juki DNU 1541 is a top pick for pros, but if you’re just starting out, the Singer 4432 might be more your speed.

Don’t forget about the roller foot and post bed design – they’re game-changers for working around tricky curves and tight spaces.

Whether you’re stitching up sneakers or cobbling together boots, the right machine will have you walking on air. Ready to step up your shoe game?

Table Of Contents

Key Takeaways

- Power up your shoe game with a heavy-duty machine that can handle thick leather like a champ. You’ll want a workhorse with muscles, not a delicate flower that’ll wilt at the sight of a boot.

- Don’t forget the dynamic duo of shoe sewing: the roller foot and post bed design. They’re like Batman and Robin for your stitching adventures, helping you navigate tricky curves and tight spaces with ease.

- Speed demons, rejoice! Machines like the Singer 4432 can zip through projects at 1,100 stitches per minute. That’s faster than you can say "these boots are made for walking"!

- Consistency is key when it comes to stitch quality. Look for a machine with adjustable tension and stitch length – it’s the secret sauce that’ll make your shoes look professionally crafted, not like a DIY disaster.

Choosing the Right Sewing Machine for Shoes

Picking the right sewing machine for your shoe projects is key to getting the best results. You’ll want to think about things like the type of shoes you plan to make, the materials you’ll be using, and the specific features and capabilities of different machines.

Leather Thickness and Machine Capabilities

When choosing a sewing machine for leather, you need to think about the thickness of the leather and what the machine can do. Here are some key things to keep in mind:

- Leather Weight: The weight of the leather you’ll be working with is important. Basic machines might’ve trouble with thicker leather, and their needles might break. On the other hand, industrial machines with stronger needles can make bigger holes in thinner leather, which mightn’t be what you want.

- Needle Size: Choose heavy-duty needles made for working with tough fabrics like leather.

- Stitch Length: Make sure the machine lets you adjust the stitch length to match different leather thicknesses and keep the thread from snapping.

- Motor Power: Look for a machine with a powerful motor to handle the resistance of leather and other heavy-duty fabrics.

Roller Foot and Post Bed Design Importance

When choosing a sewing machine for shoes, the roller foot and post bed design are key considerations. These features impact your ability to sew shoe uppers efficiently and reach tight spaces.

| Sewing Machine Feature | Roller Foot Benefits | Post Bed Advantages |

|---|---|---|

| Roller Foot | Allows for detailed edge sewing, ensuring a neat finish. | Provides access to tight spaces and facilitates sewing of hollow, tubular, and shaped items. |

| Post Bed Design | N/A | Essential for boot construction and professional shoe repair, offering stability and the ability to reach specific areas. |

| Machine Recommendation | 7591/7592 Post-Bed high-speed Machines | Janome HD9 Professional, Janome 1600P, and Singer 4423 Heavy Duty |

Top 6 Best Sewing Machines for Shoes

Whether you’re a seasoned shoemaker or just starting, choosing the right sewing machine for your shoe projects is really important. In this article, we’ll guide you through selecting the best sewing machine for shoes from our top 6 picks, considering factors like leather thickness, machine capabilities, and user-friendliness.

1. Juki DNU 1541 Sewing Machine

If you’re after a single-needle, straight stitch, walking foot industrial sewing machine, the Juki DNU 1541 is a great option. It’s built for heavy-duty fabrics like leather and comes with a sewing machine head, table, stand, motor, light, drawer, and all the bits and bobs you need to get started.

This bad boy can sew up to 2500 stitches per minute, with a max stitch length of 9mm. It’s a bit of a beast, weighing in at 80 (units unspecified, sorry about that!). It’s got some serious power behind it, thanks to its industrial clutch motor.

The Juki DNU 1541 is a solid choice for your shoemaking projects, but there are a few things to keep in mind. It might arrive with a few scratches, and you’ll definitely need to buy some machine oil as it tends to leak. It’s also a little noisy, so maybe not one for late-night crafting sessions!

Best For: The Juki DNU 1541 is best for those working with heavy-duty fabrics like leather, especially for projects like shoemaking.

- Handles heavy-duty fabrics with ease.

- Strong and reliable.

- Good for long stitch lengths.

- Can be noisy.

- Oil leaks quickly.

- Pressure foot can leave a line.

2. Heavy Duty Leather Sewing Machine

If you’re after a heavy-duty leather sewing machine, this one’s a solid choice. It’s made of iron and has a high-temperature spray paint treatment, so it’s durable and will last a long time. It’s compatible with nylon, polyester, and cotton thread, so you can use it for a range of projects. This machine is ideal for sewing and repairing bags, dolls, and canvas. Keep in mind that you’ll need to buy a motor (550w or higher) and a tabletop rack separately, and professional installation is recommended.

Best For: This heavy-duty sewing machine is ideal for crafters, hobbyists, and professionals who need to sew thick materials like leather, canvas, and denim.

- Durable construction thanks to its iron frame and high-temperature spray paint treatment

- Versatile for sewing a variety of materials, including nylon, polyester, and cotton thread

- Suitable for a wide range of projects, from bags and dolls to canvas repairs

- Requires separate purchase of a motor and tabletop rack

- Professional installation recommended for optimal performance

- Can be heavy and bulky, making it less portable than other sewing machines

3. Heavy Duty Industrial Sewing Machine

If you’re after a workhorse machine that can handle a variety of projects, the LIKARVA Heavy Duty Industrial Sewing Machine could be your new best friend. This bad boy is built like a tank with its heavy-duty metal frame and stainless steel bedframe, ready to tackle any sewing challenge you throw at it.

With a maximum speed of 3000 stitches per minute, this machine will have you zipping through projects in no time. The connecting rod type feeding mechanism makes for stable operation and precise stitching, resulting in professional-looking results every time.

The LIKARVA is versatile too. It can sew through a range of materials, from thin to medium-thick fabrics, making it a great choice for garment construction, knitting, jeans, tents, and even leather goods. So, whether you’re crafting a new wardrobe or tackling some home decor projects, this machine has you covered.

Keep in mind that this machine requires a separate electric motor, tabletop rack, and assembly. It’s also recommended to have professional knowledge for installation, so it might be a bit more involved than your average sewing machine setup. But if you’re looking for industrial-strength performance, the LIKARVA Heavy Duty Industrial Sewing Machine is a solid choice.

Best For: The LIKARVA Heavy Duty Industrial Sewing Machine is best for serious sewers who need a machine that can handle a wide range of materials and projects.

- Heavy-duty construction for long-lasting use

- High sewing speed for efficient project completion

- Versatile for sewing a wide range of materials

- Requires separate electric motor and tabletop rack

- Requires assembly and professional installation knowledge

- May be more expensive than a standard sewing machine

4. Singer 4432 Black Sewing Machine

If you’re after a budget-friendly option, the Singer 4432 Black Sewing Machine is a solid choice. This machine is a real speed demon, zipping through projects at

Best For: This machine is best for beginners and those looking for a versatile machine for a variety of projects.

- Speedy: Zips through projects at 1,100 stitches per minute.

- Durable: Full metal frame for lasting performance.

- Beginner-Friendly: Simple to set up and use, even for those new to sewing.

- Some users have reported difficulty threading the needle and achieving consistent stitch quality.

- May require additional accessories for specific projects.

- The hand chopper can be dull.

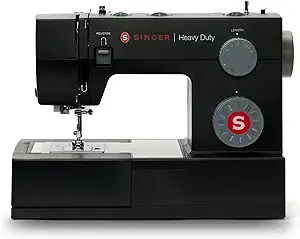

5. Singer Heavy Duty Sewing Machine

If you’re looking for a sewing machine that can handle anything you throw at it, the Singer Heavy Duty Sewing Machine might be your perfect match. This machine is built tough with its metal frame and powerful motor, ready to tackle tough fabrics like denim and canvas.

One of its standout features is speed—it can sew up to 1,100 stitches per minute, making quick work of your projects. You get creative control too, with 411 stitch applications, including basic, stretch, and decorative stitches, plus a lettering font.

The Singer Heavy Duty is easy to use, with touch button stitch selection and a clear LCD screen. The top drop-in bobbin is convenient for threading and lets you keep an eye on your thread supply.

While this machine has a lot going for it, there are a few things to keep in mind. Some users report that it struggles with multiple layers of thick fabric, and there are also reports of uneven stitch length. The lightweight construction may feel less sturdy compared to older models, and the display isn’t backlit, making it tricky to read in low light.

All in all, the Singer Heavy Duty Sewing Machine is a great choice for those seeking speed and versatility, but keep in mind its limitations with very heavy-duty projects.

Best For: The Singer Heavy Duty Sewing Machine is best for home sewers who need a machine for a variety of projects, including tough fabrics, but don’t need to tackle extremely heavy-duty projects.

- Powerful motor handles tough fabrics with ease.

- Speed of up to 1,100 stitches per minute makes quick work of projects.

- User-friendly features like touch button stitch selection and a clear LCD screen.

- Potential power limitations with multiple layers of thick fabric.

- Reports of uneven stitch length from some users.

- Display not backlit can make it difficult to read in low light.

6. Janome HD3000 Heavy Duty Sewing Machine

If you’re looking for a sewing machine that can handle anything you throw at it, the Janome HD3000 Heavy Duty Sewing Machine is a great option.

It’s a workhorse that can handle thick fabrics like denim and corduroy with ease.

The Janome HD3000 comes with a bunch of features that make sewing a breeze:

- 18 stitches

- Built-in needle threader

- Snap-on presser feet

- Push-pull bobbin winder

- Extra-high presser foot lift

Some users have reported minor issues, but Janome’s customer service is known for being responsive.

This machine is a great choice for shoe-making projects and it’s priced reasonably.

Best For: The Janome HD3000 is best for experienced sewers who need a machine that can handle thick fabrics and heavy-duty projects.

- Handles thick fabrics with ease.

- Comes with a variety of helpful features, including a built-in needle threader and extra-high presser foot lift.

- Responsive customer service from Janome.

- Some users reported minor issues with the feed dogs and foot pedal cord.

- May not be ideal for beginners.

- Requires more maintenance than digital sewing machines.

Understanding Shoe Sewing Machine Needs

Choosing the right sewing machine for shoemaking depends on what you’re working on. Whether you’re stitching leather, rubber, or other tough materials, you’ll need a machine that can handle them without a fuss and give you professional results.

Leather Thickness and Machine Type

Leather thickness and the type of sewing machine you use go hand in hand. Here’s what you need to think about:

- Leather Weight: Figure out how thick the leather is. This helps you make sure your sewing machine can handle it.

- Machine Power: Pick a machine that has enough power to sew through thick leather. A heavy-duty machine with a strong motor is your best bet.

- Stitch Density and Needle Size: Adjust your stitch density and needle size based on the leather thickness. For thicker leather, use heavy-duty needles and a lower stitch density to avoid breaking the needle.

Single Needle and Double Needle Post Bed Machines

For shoemaking, single-needle and double-needle post-bed machines are the way to go. These industrial sewing machines are specifically designed for stitching shoes, leather goods, and car interiors. The post-bed design allows for stitching hollow, tubular, and shaped items—a must-have for shoemakers. Single-needle machines are great for detail work, while double-needle machines offer speed and efficiency for thicker materials.

Roller Foot and Machine Brand Options

I couldn’t find any info about roller foot benefits. But, I can tell you about the Janome HD9 Professional and its price.

The Janome HD9 Professional is a high-speed, durable machine, perfect for sewing and quilting. It offers a large workspace, a smooth and quiet experience, and a range of accessories. It’s priced at $1,699, but you may be able to find it for less at other retailers.

Key Features for Successful Shoe Sewing

If you’re thinking about sewing shoes, there are a few key features that can make all the difference. You’ll want a machine that can handle thick materials and leather with ease, has a powerful motor, and can use thicker needles for heavy-duty stitching.

Motor Strength and Needle Features

Sewing shoes is a whole different ball game. You need a machine with some serious muscle. A motor that’s 60% stronger than your average sewing machine will make light work of thick fabrics. And an advanced clutching system that transfers power from the motor to the needle means it’ll glide through layers of toughened fabric.

But it’s not just about the motor. You need a machine that can accommodate a thick needle to tackle stubborn fabrics. And don’t forget about stitch consistency—you want even, quality stitches that’ll make your creations look professional.

Presser Foot and Feed Mechanism Importance

Sewing shoes is all about getting those stitches right, and that’s where the presser foot and feed mechanism come in. They’re the unsung heroes that make sure your stitches are even, your fabric feeds smoothly, and the tension is just right.

Imagine trying to sew a sleek leather shoe, but your presser foot is slipping and sliding, causing uneven stitches and fabric bunching. Not a good look, right? That’s why choosing the right presser foot is key.

For shoe sewing, a walking foot or roller foot are your go-to choices. They grip and feed the fabric like a dream team, making sure you get smooth stitching and consistent results. So, when you’re shopping for a sewing machine, look out for these specialty presser feet or machines that offer them as optional accessories.

The feed mechanism also plays a big part in successful shoe sewing. You want a machine with a strong feed mechanism that can handle thick, heavy-duty fabrics and multiple layers without skipping a beat. Look for machines with a good reputation for handling fabric feeding, and your shoe sewing projects will be off to a smooth start.

Build Quality and Durability for Long-Term Use

When you’re looking for a shoe sewing machine, build quality is your best friend. You’ll want a machine that’s built like a tank to handle the tough materials you’ll be throwing at it. Look for models with sturdy metal frames – they’re the backbone of a long-lasting machine. Here are some key things to keep in mind:

- Solid metal construction for stability

- High-quality gears and internal components

- Reinforced needle bar for heavy-duty use

- Robust motor built for extended operation

- Durable feed dogs that won’t wear down quickly

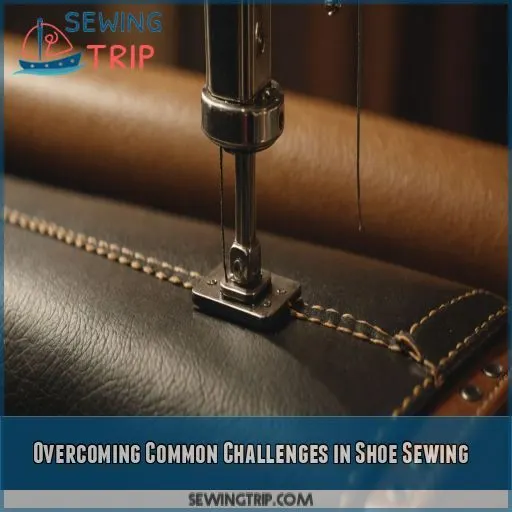

Overcoming Common Challenges in Shoe Sewing

Sewing shoes is a whole different ballgame, with challenges that’ll test your skills and patience. From working with thick leather and rubber soles to keeping your stitches looking sharp, let’s dive into how to conquer these hurdles and take your shoe-making to the next level.

Working With Thick Leather and Rubber Soles

Thick leather and rubber soles can be a beast to tame, but don’t sweat it!

You’ll need a heavy-duty zigzag sewing machine that can handle the tough stuff.

Choose the right needle types for your material – leather needles for uppers and a walking foot for even feeding.

When attaching soles, patience is key.

Take it slow, adjust your stitch tension, and you’ll be crafting killer kicks in no time!

Mastering Consistent Stitch Quality and Length

- Stitch tension: Your thread’s tightrope act

- Needle size: The Goldilocks principle—not too big, not too small

- Feed dog: Your fabric’s personal chauffeur

- Foot pressure: The gentle giant of your machine

Troubleshooting Common Issues and Errors

Ever felt like your shoe project’s turned into a comedy of errors?

Don’t sweat it! We’ve all been there.

From pesky needle breakages to frustrating thread jams, shoe sewing can be a rollercoaster.

But here’s the secret: most issues have simple fixes.

Whether you’re tackling skipping stitches, battling uneven tension, or wrestling with bobbin problems, we’ll help you get back on track.

Ready to turn those hiccups into victories?

Frequently Asked Questions (FAQs)

What kind of sewing machine do you need to sew shoes?

Like a workhorse in your stable, you’ll need a heavy-duty sewing machine for shoes. You’ll want one with a walking foot, strong motor, and ability to handle thick materials. Don’t forget adjustable stitch length and tension control.

What machine is used to make shoes?

You’ll need a heavy-duty sewing machine to make shoes. Look for models with a walking foot and powerful motor. Industrial machines like the JUKI DNU-1541 or Consew 206RB-5 are top picks for serious shoemakers.

What do you need to sew shoes?

So, you’ll need a few key tools to get started. You’ll definitely want a heavy-duty sewing machine, leather needles, and sturdy thread. Don’t forget a walking foot attachment, leather scissors, and a hole punch. You’ll also want pattern-making tools and leather glue.

What is the name of the shoe sewing machine?

You’ll want a post-bed sewing machine for shoes. It’s got a raised arm that lets you maneuver tricky angles. Popular models include the Cowboy CB3200 and Juki TNU- They’re real workhorses for shoemakers!

Can regular sewing machines handle shoe repair tasks?

Ever wondered if your trusty sewing machine can tackle shoe repairs? While regular machines can handle basic tasks, they’ll struggle with thick leather. You’ll need a heavy-duty model with a walking foot for serious shoe work.

How often should shoe sewing machine needles be replaced?

You’ll want to replace your shoe sewing machine needles every 8-10 hours of use. Keep an eye out for signs of wear, like skipped stitches or fabric snags. Trust your gut—if something feels off, it’s time for a fresh needle!

What thread types work best for shoe construction?

You’ll want to use bonded nylon or polyester thread for shoe construction. They’re strong, durable, and resist abrasion. For leather shoes, go with waxed thread. It’ll slide through easily and create water-resistant seams. Always match thread weight to your fabric.

Are computerized sewing machines suitable for shoemaking projects?

You’ll find computerized sewing machines can be great for shoemaking. They offer precision stitching and programmable patterns, perfect for intricate designs. However, you’ll want to make sure they’ve got enough power to handle thick materials like leather.

How to maintain proper tension when sewing shoe materials?

You’ll want to start with a balanced upper and lower tension. Test on scrap material, adjusting gradually. Keep your machine clean and well-oiled. Remember, different shoe materials may require tweaks, so don’t be afraid to experiment!

Conclusion

Who knew finding the best sewing machine for shoes could be such a soul-searching experience?

But fear not, intrepid cobbler!

Armed with our top 6 picks, you’re ready to stitch your way to footwear fame.

Whether you’re a pro or just dipping your toe in, there’s a perfect match waiting.

So lace up your creativity, and let’s kick off your shoe-making adventure.

Your feet (and your customers’) will thank you!