This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

The seam on a professionally made garment looks clean, secure, and almost invisible from the outside, yet the raw edges inside appear finished with multiple rows of thread that prevent fraying and add durability. That’s the work of a serger, and it’s the difference between homemade clothing that looks amateur and pieces that rival store-bought quality.

If you’ve been wrestling with knit fabrics that stretch out of shape, edges that unravel after a few washes, or seams that pucker despite your best efforts, a reliable serger sewing machine solves these frustrations while cutting your finishing time in half.

The challenge isn’t whether you need one, it’s identifying which models deliver consistent performance without constant tension adjustments or threading headaches. We’ve tested the current lineup to pinpoint machines that handle everything from delicate jersey to heavyweight fleece with the same dependable results.

Table Of Contents

Key Takeaways

- A reliable serger transforms homemade garments into professional-quality pieces by simultaneously trimming fabric edges and creating secure, fray-resistant seams with multiple threads, cutting finishing time in half compared to traditional sewing machines.

- Essential features that separate dependable sergers from frustrating machines include four-thread capability, differential feed systems (0.5-2.0 ratio) for stretch control, automatic thread tension, color-coded threading guides, and adjustable stitch length (0.5-4.0mm) and width (0-7mm) for precision across fabric types.

- The top-performing sergers for 2026 balance ease of use with professional results, with standout models like the Singer ProFinish 14CG754 ($250-range), Juki MO1000 (air threading technology), and Bernette B48 (coverstitch capability) offering different advantages based on your skill level and project needs.

- Proper maintenance—including weekly cleaning of feed dogs and loopers, oiling pivot points every 20-40 hours, replacing needles every 2-4 hours of continuous sewing, and changing knives when nicks appear—protects your investment and ensures consistent stitch quality for years.

Key Features of Reliable Serger Machines

When you’re shopping for a serger that won’t let you down, knowing what features actually matter makes all the difference. The right combination of capabilities can transform your sewing from frustrating to easy, especially when you’re tackling stretchy fabrics or racing against a deadline.

If you’re weighing costs alongside capabilities, understanding entry-level sewing machine pricing can help you decide whether a dedicated serger fits your budget and skill level.

Here are the seven essential features that separate reliable sergers from machines that’ll gather dust in your closet.

Multiple Thread Capability

You’ll find reliable sergers offering fourthread capacity as the foundation for professional seam quality, though high-end models extend to five or six thread configurations for decorative work. Thread count options directly impact your finished seams, with colorcoded thread guides simplifying looper threading through upper and lower pathways.

Semiautomatic threading features reduce setup frustration, while thread capability determines the versatility of stitches you can achieve.

Differential Feed System

Your differential feed system functions as the control center for fabric handling, especially on stretchy fabrics and knit fabrics. The feed dog roles involve independent front and back dogs that adjust their speed ratio from 0.5 to 2.0, giving you stretch control across various materials.

This fabric compatibility mechanism prevents edge waves on jersey while stabilizing woven edges, making fabric control easy through simple dial adjustments.

Adjustable Stitch Length and Width

Beyond fabric feeding, adjustable stitch length and stitch width give you precision over every seam. Most sergers offer a length range from 0.5 to 4.0 millimeters and width variants spanning 0 to 7 millimeters, letting you customize edge finishes for different fabrics.

Presets customization simplifies common tasks, while calibration importance grows with frequent use—regular maintenance keeps your serger delivering consistent results across production runs.

Color-Coded Thread Guides

Visual threading cues simplify setup efficiency on every serger machine, cutting your learning curve from hours to minutes. Color-coded threading paths match each spool to its designated looper or needle—upper looper green, lower looper red, needles blue—so you won’t cross threads during setup.

Beginner sewing enthusiasts appreciate the durability of printed guides that resist fading, ensuring weaving and stitching remain trouble-free for years.

Automatic Thread Tension

Automatic thread tension eliminates guesswork by adjusting upper and lower thread pressure in real time, balancing stitches across woven, knit, and stretch fabrics. Micro sensor adjustments detect fabric thickness and modify tension controls instantly, preventing puckering and skipped stitches.

Thread coordination ensures even seam finishes without manual tweaking, while system diagnostics alert you to worn components before they compromise your weaving quality—features praised in serger machine reviews.

Built-in Knife for Trimming

Your serger machine’s built-in knife system trims fabric edges in perfect sync with stitch formation, delivering clean seam finishing and precise edge finishing every time. Blade depth control lets you adjust cut width from 0.5 mm to 2.5 mm, while knife guard systems with retractable housings protect you during threading.

Regular knife maintenance, including blade replacement and alignment checks, ensures consistent trimming techniques across heavyweight knits and delicate synthetics on your overlock machine.

LED Lighting and Visibility

Proper task lighting transforms your serger workspace, and LED brightness above 1000 lumens at 24 inches delivers clear visibility across the needle plate. Color temperature between 4000K and 4500K reduces eye strain during extended sessions, while wide viewing angles minimize hard shadows on fabric surfaces.

- High CRI above 90 ensures accurate thread and fabric color perception

- Diffused lenses with glare reduction protect your eyes on glossy materials

- Adjustable positioning directs light exactly where seams form

- Energy-efficient operation uses 80 percent less power than incandescent fixtures

Benefits of Using a Serger Sewing Machine

You might wonder why so many sewers swear by their sergers once they’ve made the investment. The answer lies in a handful of practical advantages that make these machines indispensable for certain projects.

Let’s look at the key benefits that set sergers apart from traditional sewing machines.

Professional-Looking Seam Finishes

You’ll transform homemade garments into runway-worthy pieces when you master the seam-finishing capabilities sergers offer. With adjustable stitch length and overlock techniques, you can create professional-looking seams that rival ready-to-wear clothing.

Your stitch quality improves dramatically with these finishing edge options, giving you complete control over every detail.

| Stitch Type | Best Application |

|---|---|

| Three-thread overlock | Lightweight fabric binding with minimal bulk |

| Four-thread overlock | Woven fabrics requiring stronger edge trimming |

| Rolled hems | Delicate finishes on scarves, napkins |

| Flatlock stitches | Decorative seams with exposed threads |

| Blind stitch | Hidden finishes on knit garments |

Prevention of Fabric Fraying

Your fabric edges stay locked in place when you use overlocking stitches that secure raw edges with multiple threads simultaneously. Serger maintenance keeps tension balanced, preventing weak points that initiate unraveling.

With fabric edge control and proper fray prevention methods, you’ll achieve professional-looking seams through fabric stabilization and finishing edges with rolled hems, giving you complete mastery over fabric edge finishing.

Efficient Sewing on Knits and Stretch Fabrics

When working with knit fabrics, you’ll find differential feed lets the top and bottom layers move at different speeds to prevent waves and puckering. Here’s what makes your stretchy fabric sewing smooth:

- Knit Fabric Prep: Prewash knits to remove shrinkage, then cut with sharp scissors without stretching the material

- Serger Thread Choice: Use polyester or cotton-polyester blends for durable, flexible seams

- Stretch Stitch Tips: Apply a 4-thread overlock for combined seam strength and edge finishing

- Fabric Stretch Control: Adjust differential feed ratios higher for jersey, lower for light-stretch wovens to maintain stability

Knit Seam Finishing with adjustable stitch length ensures your serger machine accommodates athletic wear and delicate knits with equal precision.

High-Speed Stitching for Productivity

Speed optimization in your serger machine transforms production timelines, with modern models reaching up to 1500 stitches per minute without sacrificing stitch consistency. You’ll complete seams in seconds while maintaining professional-looking results through precise thread management and fabric handling.

High-speed stitching delivers consistent seam quality across multiple projects, letting you finish garments faster while preserving the structural integrity that slower machines achieve.

| Sewing Speed Range | Productivity Impact |

|---|---|

| 1000-1300 stitches/min | Standard garment assembly |

| 1400-1500 stitches/min | Commercial production rates |

| Adjustable stitch length | Tailored sewing efficiency |

Decorative and Functional Stitch Options

Beyond speed, your professional serger unlocks creative stitch variety through adjustable stitch length and width controls, letting you craft rolled hems and decorative edge finishing on everything from athletic wear to formal garments. Stitch versatility transforms basic seaming into fabric embellishment opportunities, with thread effects and sewing techniques that enhance your work.

- Satin stitches deliver polished edge finishing with dense, smooth coverage across wide areas

- Rolled hems create delicate, narrow borders ideal for lightweight chiffon and organza fabrics

- Flatlock stitches join seams with low-profile construction suited for stretch knits and activewear

- Shell stitch patterns introduce scalloped edges perfect for garment borders and home decor projects

- Adjustable tension settings control stitch density, balancing decorative appeal with fabric durability

Top 8 Reliable Serger Sewing Machines

You’ve learned what a serger can do, and now it’s time to see which machines actually deliver on those promises.

The models below represent the most reliable options available in 2026, each tested for durability, ease of use, and consistent performance.

Here’s what you need to know about the top eight sergers worth your investment.

1. Singer ProFinish Serger Machine

The Singer ProFinish 14CG754 offers adaptable 2-3-4 thread configurations with speeds reaching 1,300 stitches per minute, making it suitable for beginners and experienced sewers alike. You’ll appreciate its color-coded lay-in threading system, which simplifies setup, and the differential feed that manages everything from delicate fabrics to thicker materials.

At 13.5 pounds with a built-in carry handle, you can move this portable serger easily. The free arm attachment lets you tackle sleeves and cuffs, while four built-in rolled hem options expand your finishing capabilities considerably.

| Best For | Sewers of all skill levels who want professional-quality finishing on garments and home decor projects without spending hours on setup. |

|---|---|

| Thread Capability | 2-3-4 thread |

| Weight | 13.5 pounds |

| Material | Metal, Plastic |

| Speed | 1,300 spm |

| Threading System | Color-coded lay-in |

| Hem Feature | 4 built-in rolled |

| Additional Features |

|

- Color-coded threading makes setup way easier than traditional sergers, especially if you’re new to this

- Handles everything from delicate silks to heavier fabrics thanks to the differential feed system

- Lightweight and portable at 13.5 pounds, so you can take it to classes or store it without much hassle

- Threading can still be tricky at first despite the color coding, so expect a learning curve

- The thread guide feels a bit flimsy according to some users

- Creates more fabric mess during cutting and serging than you might expect

2. Juki Portable Serger Sewing Machine

The Juki Portable Serger weighs just 6.9 kilograms and features a compact 10.6″D x 13.6″W x 11.6″H design that you can move effortlessly between sewing spaces.

You’ll find 2-3-4 thread configurations with automatic rolled hem capability, plus color-coded threading paths that cut setup time dramatically.

Its differential feed ratio of 0.7:2.0 accommodates everything from lightweight silks to heavier materials, while the dedicated knife drive mechanism trims seam allowances cleanly as you sew.

At 1,500 stitches per minute maximum speed, you’ll finish projects quickly without sacrificing quality.

| Best For | Home sewers and small business owners who need a reliable, portable serger for finishing seams on light to heavy fabrics without the complexity of coverstitch functions. |

|---|---|

| Thread Capability | 2-3-4 thread |

| Weight | 15.2 pounds |

| Material | Aluminum |

| Speed | 1,500 spm |

| Threading System | Color-coded breakaway |

| Hem Feature | Automatic rolled |

| Additional Features |

|

- Handles a wide fabric range with differential feed (0.7:2.0 ratio) and sews up to 1,500 stitches per minute

- Compact and lightweight at 6.9kg, making it easy to move or store when not in use

- Color-coded threading and automatic rolled hem feature simplify setup and operation

- No coverstitch or coverhem capability limits finishing options for certain garment types

- Manual threading process can be tricky for beginners despite color-coded guides

- Instruction manual lacks detailed stitch guidance, so you might need to search for extra tutorials online

3. Janome White Serger Machine

The Janome White Serger delivers automatic thread tension that adjusts to fabric thickness, maintaining consistent stitches at speeds up to 1,300 stitches per minute. Its all-metal frame construction provides rigid stability during high-speed serging and reduces vibration.

Color-coded threading guides simplify setup, while the built-in knife trims excess fabric edges as you work. The differential feed automatically compensates for stretch fabrics to prevent waves or puckering, and LED lighting ensures a bright, shadow-free view of your stitch area.

| Best For | Beginners and developing fashion enthusiasts who want to create professional-looking hems and work with various fabrics like denim, knits, and canvas without breaking the bank. |

|---|---|

| Thread Capability | 3-4 thread |

| Weight | 14.3 pounds |

| Material | Metal |

| Speed | Standard |

| Threading System | Color-coded guides |

| Hem Feature | Quick change rolled |

| Additional Features |

|

- Color-coded threading guides and lay-in system make setup much easier than traditional sergers

- Differential feed prevents fabric stretching and puckering on tricky materials like knits

- Speeds up to 1,300 stitches per minute with sturdy metal frame that stays stable even at high speeds

- Threading can still be tricky for complete beginners despite the color-coded guides

- No storage case for accessories and the machine cover isn’t very durable

- Can get noisy at higher speeds and tension may need occasional adjusting

4. Juki MO1000 Serger Machine

Air threading transforms setup on the Juki MO1000, automatically passing threads through loopers with the push of a button instead of manual fiddling. You’ll also find automatic needle threading for both right and left needles, reducing strain and speeding your workflow.

The 72.4 mm throat clearance accommodates bulky seams, while adjustable differential feed prevents skipped stitches on knits. Built-in LED lighting illuminates your work area, and the waste catcher keeps trimmings contained.

This 4-thread serger manages 2, 3, and 4-thread configurations with quiet, steady operation.

| Best For | Beginners and experienced sewers who want professional-looking serged seams with less setup hassle, especially when working with knits and fabrics that fray. |

|---|---|

| Thread Capability | Air threader system |

| Weight | 24.4 pounds |

| Material | Georgette |

| Speed | Quiet operation |

| Threading System | Automatic & air |

| Hem Feature | Various stitching |

| Additional Features |

|

- Air threader and automatic needle threading eliminate the most tedious part of serger setup

- Quiet operation with reduced vibration makes it comfortable for longer sewing sessions

- Handles multiple thread configurations (2, 3, and 4-thread) for different project needs

- Air threader can be finicky and may not work consistently for all users

- Requires frequent cleaning to prevent thread jams and blockages

- Waste catcher doesn’t always fit flush, letting some trimmings escape

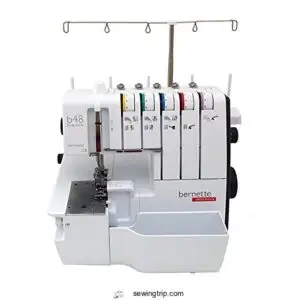

5. Bernette B48 Serger Coverstitch Machine

Built-in coverstitch capability separates the Bernette B48 from standard sergers, offering overlock and hemming functions in one 21-pound machine. You’ll work with 2, 3, 4, and 5 thread combinations across 23 built-in stitches, while color-coded threading paths guide setup and reduce errors.

The differential feed manages fabrics from fine knits to thick denim without puckering, and the 1300-stitch-per-minute speed keeps projects moving. LED lighting reduces eye strain during precision work, though beginners may need practice to master the threading system.

| Best For | Sewers who need professional hemming and edge-finishing capabilities beyond what a regular sewing machine or basic serger can handle. |

|---|---|

| Thread Capability | 23 built-in stitches |

| Weight | 21 pounds |

| Material | Plastic |

| Speed | 1,300 spm |

| Threading System | Manual threader |

| Hem Feature | Adjustable widths |

| Additional Features |

|

- Combines overlock, coverstitch, and chain stitch in one machine, eliminating the need for multiple devices

- Handles everything from delicate knits to heavy denim thanks to differential feed and adjustable settings

- Fast 1300-stitch-per-minute speed with LED lighting for efficient, precise work

- Threading system has a learning curve that can frustrate beginners despite color-coded guides

- At $999 and 21 pounds, it’s a significant investment in both cost and counter space

- Some users report receiving units with missing or damaged parts

6. Bernette Funlock Coverstitch Sewing Machine

Coverstitch machines often tackle hemming on knits and activewear, and the Bernette Funlock delivers three coverstitch options plus a chain stitch in a 19.26-pound package. You’ll choose between 2.8 mm narrow and 5.6 mm wide coverstitch configurations for different fabric weights, while color-coded threading paths speed up setup on this grey-and-white unit.

The 87-millimeter work area accommodates bulkier projects, and LED lighting keeps stitches visible during detail work. At $699.00, you’re investing in dedicated hemming capability, though the 1/8-inch presser foot clearance limits thicker materials.

| Best For | Sewers who regularly work with knits and need professional hemming capabilities, especially for activewear and stretchy fabrics. |

|---|---|

| Thread Capability | Coverstitch machine |

| Weight | 19.26 pounds |

| Material | Metal |

| Speed | Standard |

| Threading System | Easy threading |

| Hem Feature | Professional coverstitch |

| Additional Features |

|

- Three coverstitch options plus chain stitch give you flexibility for different fabric weights and project types

- Color-coded threading system and 87mm work area make setup easier and accommodate bulkier projects

- LED lighting helps with precision work on detailed hems and finishes

- Only 1/8-inch presser foot clearance limits your ability to work with thicker materials

- Some users found the presser foot lever design confusing and experienced threading or jamming issues

- LED light may be too bright for extended use, and the machine might not hold up for heavy commercial workloads

7. Janome Serger Sewing Machine

You’ll appreciate the Janome 800002D’s 3-or-4-thread versatility in a compact 19-pound aluminum frame measuring 15 x 13.5 x 14.5 inches. This serger manages elastic insertion into spandex fabrics while delivering professional rolled hems through color-coded threading charts, though you’ll need patience when changing thread colors.

The adjustable cutting width spans 3.1mm to 7.3mm, and the extra-high presser foot lifter accommodates varied fabric thicknesses.

At its price point, you’re gaining whisper-quiet operation and an electronic foot pedal, but this 110-volt machine works only in US outlets and lacks a dust cover.

| Best For | Sewers who want professional-quality seams and rolled hems without the bulk of industrial equipment, especially if you’re working with stretchy fabrics or want to elevate homemade garments. |

|---|---|

| Thread Capability | 3-4 thread overlock |

| Weight | 19 pounds |

| Material | Aluminum |

| Speed | Quiet operation |

| Threading System | Color-coded chart |

| Hem Feature | Built-in rolled |

| Additional Features |

|

- Handles both 3 and 4-thread stitching with adjustable cutting width (3.1mm to 7.3mm) for different fabric types

- Color-coded threading chart and extra-high presser foot make setup easier than most sergers

- Compact at 19 pounds and runs quietly, so it won’t dominate your workspace or drive you crazy

- Threading takes patience, especially when switching colors, and broken threads mean starting over

- Only works with 110-volt US outlets, so it’s not travel-friendly internationally

- Doesn’t include a dust cover, which seems like an oversight at this price point

8. Juki 5 Thread Serger Coverstitch Machine

When you’re ready to combine serging and coverstitching in one machine, the Juki MO-735 delivers 24 stitch options across five-thread configurations in a 23.1-pound white vinyl frame. You’ll find both 2-needle and 3-needle coverstitch capabilities alongside chainstitch functions, handling everything from ultra-lightweight silks to heavy denims.

The differential feed prevents stretching on knits, while color-coded guides simplify threading.

Threading challenges emerge for beginners, and some users report needle plate issues requiring adjustment, but you’re gaining professional-grade versatility for sportswear and home fashions.

| Best For | Sewers who want professional serging and coverstitching in one machine for garment construction, sportswear, and activewear projects. |

|---|---|

| Thread Capability | 24 stitch options |

| Weight | 23.1 pounds |

| Material | Vinyl |

| Speed | Fast operation |

| Threading System | Simple threading |

| Hem Feature | 5-thread safety |

| Additional Features |

|

- 24 stitch options including 5-thread safety stitch, 2 or 3 needle coverstitch, and chainstitch for versatile project capabilities

- Handles both ultra-lightweight and heavyweight fabrics with differential feed that prevents stretching on knits

- Fast, powerful, and quiet operation with color-coded threading guides

- Threading can be challenging for beginners despite color-coded guides

- Instructions are difficult to understand according to some users

- Needle plate issues reported, with needles becoming loose or bent requiring adjustment

How to Choose The Best Serger for You

Choosing the right serger isn’t about finding the most expensive model—it’s about matching features to your specific sewing projects and skill level. You’ll need to think about what fabrics you work with most often, which stitch options matter for your projects, and how comfortable you’re with threading and adjustments.

The following factors will help you narrow down your options and find a serger that delivers reliable performance without unnecessary complexity.

Assessing Fabric Types and Project Needs

Fabric Selection starts with matching your serger to what you’ll actually sew. Knits and stretchy fabrics demand a differential feed of 2.0 or higher to prevent wave necklines, while woven fabrics like cotton poplin need clean edge finishing with precise thread tension. Heavyweight denim requires sturdy blades and higher presser foot pressure, and garment construction for athletic wear benefits from 3 to 4 thread overlock at faster sewing speed for secure seams.

| Fabric Type | Recommended Feature | Project Application |

|---|---|---|

| Knits & Stretch | Differential feed 2.0+ | Athletic wear, T-shirts |

| Woven Cotton | Narrow seam, rolled edge | Home decor, quilting |

| Heavy Denim | Strong knife, high pressure | Jeans, canvas bags |

Comparing Stitch Options and Customization

Beyond fabric matching, you’ll want stitch variety that matches your ambitions. Look for machines offering overlock, rolled hems, flatlock, and coverstitch options for true stitch versatility.

Adjustable stitch length from 1 to 4 millimeters and adjustable stitch width give you thread control for delicate chiffon or thick canvas.

Customization options like micro adjustments and sewing speed dials let you handle everything from gathering ruffles to professional-grade fabric handling on technical projects.

Evaluating Ease of Use and Threading

Threading complexity can make or break your serging experience, so prioritize machines with color-coded threading paths and automatic tensioning systems that reduce your learning curve from hours to minutes.

- Color coded pegs align directly with needle points for foolproof thread management

- LED ring lights brighten threading ports to eliminate eye strain during setup

- Tension release levers let you switch between overlock and decorative stitches instantly

- Quick reference diagrams on the foot surface guide you through 3-4 thread capability configurations without hunting manuals

Considering Brand Reputation and Reviews

Brand trust rises when serger machine reviews consistently show 4-5 star averages over multiple years, signaling stable quality you can count on.

Customer feedback on threading ease, parts availability, and warranty responsiveness reveals reputation management in action.

Cross-check best serger machines across major retailers and professional forums to verify social proof before investing in your ideal model.

Balancing Budget and Value

Your budget planning starts with entry-level sergers at 150 to 250 dollars, while midrange models with differential feed cost 300 to 600 dollars.

Price comparison shows higher-end professional serger machines exceed 1000 dollars but deliver lower cost per year through durability.

For value assessment, prioritize metal frames and three-to-five-year warranties—budget-friendly doesn’t mean compromising on long-term investment strategy.

Maintenance Tips for Long-Lasting Performance

Your serger won’t stay reliable without consistent upkeep, and that means understanding what actually needs attention. A few simple habits can prevent costly repairs and keep your machine running smoothly for years.

Here’s what you need to focus on to protect your investment and maintain professional results.

Regular Cleaning and Oiling

Your serger machine maintenance begins with consistent dust removal using plastic and lint brushes on feed dogs and looper areas weekly during light use, daily for heavy projects.

Apply one to two drops of high-quality oil to pivot points every twenty to forty hours, focusing on looper shafts and tension mechanisms while avoiding needles.

Clean thread paths thoroughly, document your cleaning schedules, and always unplug before starting any serger maintenance procedure.

Replacing Needles and Knives

Sharp edges make the difference between clean finishes and frustrating jams. Replace your serger machine needle every two to four hours of continuous sewing using size 14 to 16 for most fabrics, ensuring proper needle alignment with the flat side facing back. Change the knife system when you notice visible nicks or fabric jamming, usually after six to twelve hours depending on material density.

- Unplug your sewing machine maintenance area and wear safety glasses during knife sharpening or replacement to prevent accidental injuries

- Verify needle threading paths after installing new needles, re-threading from the upper looper down to maintain correct thread tension

- Test replacement tips on scrap fabric at slow speed to confirm clean cuts and balanced stitch formation

- Store spare needles in labeled containers and knives in original packaging to prevent dulling before installation

- Follow maintenance schedules by checking thread tension on all four threads after any component replacement for even stitches

Using The Right Accessories

The right sewing machine accessories transform frustrating adjustments into smooth operation. Match specialty feet to your fabric weight, use serger-specific thread for ideal tension guides, and confirm bobbin management matches your model specifications.

Verify thread compatibility before loading spools, adjust pressure settings for each material density, and clean specialized sewing equipment regularly. These sewing tools guarantee consistent fabric handling without constant recalibration.

Storing and Organizing Serger Supplies

A cluttered workspace slows fabric finishing and risks losing critical sewing machine accessories. Organize your serger machine supplies using dedicated Storage Systems with labeled bins for Thread Management, grouping spools by color family.

Keep a magnetic tray for small sewing tools, store Cleaning Supplies in a labeled pouch, and maintain separate containers for Accessory Kits.

Proper Tool Organization protects sewing equipment and speeds project setup.

Accessing Support and Replacement Parts

When your serger machine needs attention, knowing where to turn makes all the difference. You can secure reliable support through multiple channels:

- Contact authorized Service Centers for professional Part Replacement and Warranty Claims using your model number.

- Visit manufacturer websites to order genuine OEM Parts with verified compatibility.

- Consult Online Forums for sewing machine troubleshooting insights from experienced users.

- Follow official sewing machine maintenance tips to prevent future component failures.

Frequently Asked Questions (FAQs)

What is the best serger for your money?

Mid-range sergers priced between $400 and $800 deliver the strongest value, balancing automatic tension systems with durable metal frames.

Your best serger investment depends on fabric selection, thread management needs, and desired sewing efficiency.

For those seeking more guidance, it’s helpful to review the key features of sergers that impact performance and stitching quality.

What is the best Serger machine?

The best serger machine balances thread variety, sewing speed, and machine durability to match your user experience needs. Professional serger reviews highlight models with differential feed systems and adjustable stitch options for peak performance.

For more insight into sophisticated features that improve the sewing process, explore this.

Why should I choose a reliable brand for my Serger model?

You get what you pay for, especially with a serger machine. Reliable brands deliver consistent stitch quality, longer service life, genuine parts support, and durable metal frames that won’t let you down mid-project.

Is a serger better than a sewing machine?

A serger machine excels at professional-looking seams and fabric edge finishing with differential feed, while your sewing machine offers stitch type variety for buttonholes and zippers—you’ll achieve the best results using both together.

What is the best cheap Serger?

For budget-friendly beginners, the Singer 14CG754 offers outstanding value with color-coded threading, differential feed, and rolled hem capability.

This entry-level serger delivers reliable performance on basic to intermediate projects without breaking the bank.

What is a serger sewing machine?

A serger machine is a specialized sewing tool that simultaneously cuts fabric edges while stitching, using multiple threads and loopers to create professional overlock seams that prevent fraying on various fabrics.

Do you need a serger machine for top & bottom threading?

You don’t need a serger for top and bottom threading—regular machines handle that.

Sergers excel at thread management through color-coded threading guides and air threading techniques, streamlining fabric handling with multiple thread capability for sewing efficiency.

How many stitches can a sewing Serger do?

Most sergers achieve 1,000 to 1,500 stitches per minute, depending on thread capacity and fabric impact.

Stitch density, stitch length, and stitch width adjust to match your project, while maintenance effects and speed limits influence sewing speed.

Can a serger sew backwards?

Most sergers don’t offer reverse stitching or backwards sewing capabilities like traditional sewing machines. Instead, you’ll secure seam ends through stitch locking techniques, weaving thread tails, or using end securing methods specific to your serger’s capabilities.

How are Serger Reviews rated?

Rating systems analyze customer feedback through evaluation criteria including performance testing, feature assessments, and durability scores.

Most serger machine reviews average 5 out of 5, with beginner-friendly threading and consistent stitch quality driving top ratings.

Conclusion

The right tool makes all the difference between frustration and finished projects you’re proud to wear. Investing in reliable serger sewing machine reviews narrows your options to models that handle tension adjustments, thread multiple loopers without tantrums, and deliver consistent stitch quality across fabric weights.

Your next garment deserves seams that won’t unravel after the first wash. Choose a machine that matches your skill level and project ambitions, then watch your sewing transform from adequate to outstanding.