This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A single misaligned stitch on a logo cap can cost you the customer, the sale, and your reputation—commercial hat embroidery leaves zero margin for error. Unlike flat garments that forgive minor tension issues, curved cap surfaces exaggerate every mechanical weakness in your stitching equipment, turning mediocre machines into production bottlenecks that drain both time and profit.

The difference between the 5 best hat stitching machines and budget alternatives isn’t just feature counts or price tags—it’s the engineering precision that delivers clean 12,000-stitch designs on structured six-panel caps without puckering, thread breaks, or registration drift.

Professional embroiderers who’ve evaluated dozens of models recognize that multi-needle systems, optimized hooping mechanisms, and sturdy tension controls separate reliable workhorses from machines that promise versatility but deliver inconsistent results when tackling headwear’s unique challenges.

Table Of Contents

Key Takeaways

- Multi-needle machines with 4-16 needles eliminate manual thread changes and deliver superior stitch quality on curved cap surfaces compared to single-needle systems that require constant operator intervention between colors.

- The embroidery area you choose determines project scope—look for 5×7 inch hoops with adjustable cap frames and magnetic hooping systems that secure curved brims without fabric distortion or compression.

- Commercial profitability hinges on matching machine speed (800+ stitches per minute), automation features like automatic trimming, and needle configuration to your specific production volume and design complexity requirements.

- Proper maintenance including daily lint removal, weekly deep cleaning of thread paths, and preventive servicing every 200 hours prevents 70% of embroidery failures and extends machine lifespan from 5 years to 15 years.

Top 6 Hat Stitching Machines Reviewed

Choosing the right hat embroidery machine can transform your production capabilities, whether you’re running a small custom shop or scaling up for commercial orders.

For businesses just starting out, investing in embroidery machines for small business ensures you get features that grow with your demand without overspending upfront.

The machines below represent the best options across different price points and feature sets, each offering specific advantages for hat decoration work.

Here’s what you need to know about the top six models that consistently deliver quality results on curved cap surfaces.

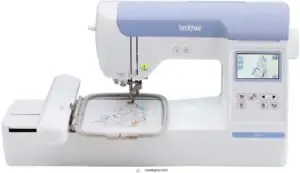

1. Brother Embroidery Machine

Brother embroidery machines deliver the precision you’ll need for consistent cap work, with up to 1,000 stitches per minute on select models and automatic needle threading that cuts setup time. Their cap frame compatibility manages curved hat surfaces, while automatic color sort and frame detection simplify multi-color logo runs.

You’ll find built-in lettering fonts suitable for team emblems, USB or WiFi design transfer for custom logos, and jump stitch trimming that keeps designs clean between color changes.

Entry-level units offer intuitive threading paths for beginners, while professional-grade models support multiple needle configurations for complex production runs.

| Best For | Embroidery enthusiasts working with knits, stretchy fabrics, or detailed designs who need quick stabilization without pinning. |

|---|---|

| Brand | Sulky |

| Weight | 5.6 ounces |

| Primary Use | Embroidery stabilization |

| Color | White |

| Material | Non-woven |

| Skill Level | Beginner-friendly |

| Additional Features |

|

- Irons on in seconds and tears away cleanly without leaving residue, saving time on prep and cleanup

- Works across multiple techniques including monogramming, quilting, and machine embroidery with Brother machines

- Prevents fabric shifting and puckering during stitching, especially helpful for stretchy materials

- May need re-ironing for hand-embroidery projects, adding extra steps

- Too flimsy for large, complex designs or patch-making that needs stronger support

- Can leave shiny iron marks on fabric if heat settings aren’t carefully managed

2. Dritz Dual Marking Pen for Fabric

Before you start stitching, accurate design placement makes the difference between professional results and wasted materials. The Dritz Dual Marking Pen (Model 673-60) gives you two marking options in one 0.352-ounce tool: blue water-soluble ink that wipes clean with a damp cloth, and purple air-soluble ink that disappears within 24 to 72 hours depending on humidity.

You’ll get precise marks for cap alignment, seam allowances, and logo positioning on washable fabrics, though you should test on a fabric swatch first since some red or pink dyes may resist removal.

| Best For | Sewers, quilters, and embroiderers who need temporary markings for pattern transfers, seam allowances, or design placement on washable fabrics. |

|---|---|

| Brand | Dritz |

| Weight | 0.352 ounces |

| Primary Use | Marking and tracing |

| Color | Blue |

| Material | N/A |

| Skill Level | Beginner-friendly |

| Additional Features |

|

- Two marking options in one pen—blue ink wipes off with water, purple ink disappears on its own within 24-72 hours

- Makes precise, clean lines for accurate pattern placement and alterations

- Lightweight and easy to handle at just 0.352 ounces

- Purple ink can fade quickly (sometimes within 30 minutes) if you’re working slowly

- May bleed through on thin or delicate fabrics like lining material

- Blue ink side tends to dry out faster than the purple side with regular use

3. Singer Professional Metal Frame Serger Machine

While marking guides your placement, finishing seams requires a different kind of precision. The Singer Professional 5 14T968DC shifts your workflow from embroidery to seam construction with its 2-3-4-5 thread configurations, covering overlock, flatlock, rolled hems, and cover stitches in one 18.6-pound metal frame unit.

You’ll achieve 1,300 stitches per minute with self-adjusting tension across lightweight to medium fabrics, though threading configurations demand 3-10 minutes per changeover and mechanical maintenance like tightening screws over time.

| Best For | Experienced sewers who need professional-grade seam finishing and are comfortable with threading adjustments and occasional mechanical upkeep. |

|---|---|

| Brand | Brother |

| Weight | 18.6 pounds |

| Primary Use | Serging and coverstitching |

| Color | Various |

| Material | Metal |

| Skill Level | Intermediate to advanced |

| Additional Features |

|

- Fast 1,300 stitches per minute with automatic tension adjustment saves time on large projects

- Versatile 2-3-4-5 thread system handles everything from rolled hems to cover stitches

- Solid metal frame construction at 18.6 pounds provides stability for consistent results

- Threading setup takes 3-10 minutes when switching configurations, slowing down workflow

- Requires mechanical maintenance like tightening screws over time

- Not beginner-friendly due to complex threading and configuration changes

4. Brother Computerized Sewing Embroidery Machine

Combining sewing versatility with embroidery precision, the Brother SE1900 delivers 240 built-in stitches alongside 138 embroidery designs through a 3.2-inch color touchscreen interface. You’ll work within a 5″ x 7″ embroidery field using USB-imported custom files, though you’re limited to 120-volt US operation in this 22-pound computerized unit.

Before investing in the SE1900, review common embroidery machine applications to ensure its capabilities match your creative projects.

Automatic needle threading and drop-in bobbin systems reduce setup time between sewing projects and embroidered personalization, while 11 fonts handle monogramming without external software for straightforward customization workflows.

| Best For | Crafters and sewing enthusiasts who want to tackle both everyday sewing projects and personalized embroidery work without switching machines. |

|---|---|

| Brand | Brother |

| Weight | 22 pounds |

| Primary Use | Sewing and embroidery |

| Color | Various |

| Material | Metal |

| Skill Level | Intermediate |

| Additional Features |

|

- 240 stitches and 138 embroidery designs give you tons of creative options right out of the box

- Touchscreen interface and automatic threading make setup quick and beginner-friendly

- USB compatibility lets you import custom embroidery files to expand beyond built-in designs

- No extension table included, so you’ll need to buy one separately for larger quilting projects

- Only works with 120-volt US power, limiting where you can use it

- Requires specific 60-weight bobbin thread for embroidery, adding an extra supply cost

5. Brother Embroidery Machine PE800

The PE800 offers dedicated embroidery functionality, featuring 138 built-in designs and 11 font styles on a 5″ x 7″ working field. Its 3.2-inch LCD touchscreen interface allows for easy navigation.

You can import custom designs via USB port, while the automatic needle threading and drop-in bobbin systems streamline your workflow between projects.

Weighing 17.64 pounds and operating on 120-volt US-only power, this machine efficiently handles monogramming and lettering. However, quality backing materials and thread are essential to optimize stitch quality, especially for hat embroidery applications.

| Best For | Home embroiderers and small business owners who want a dedicated machine with a large work area for custom designs, monogramming, and mid-sized projects. |

|---|---|

| Brand | Brother |

| Weight | 17.64 pounds |

| Primary Use | Embroidery designs |

| Color | Metal/plastic |

| Material | Metal and plastic |

| Skill Level | Beginner to intermediate |

| Additional Features |

|

- 138 built-in designs and 11 font styles give you plenty of creative options right out of the box

- 5″ x 7″ embroidery area handles larger projects without constant re-hooping

- USB port lets you import your own designs and expand beyond the built-in library

- Limited on-board editing means you’ll need to do most design work on your computer

- Hoops don’t work with other Brother models, so you can’t share accessories if you own multiple machines

- Design previews from USB drives aren’t always clear, making it hard to identify files at a glance

6. Janome Embroidery Machine

The Janome MB-4S brings 15-needle capacity and a generous 20″ x 14″ embroidery field to your workspace, accommodating complex hat designs without frequent thread changes.

At 64 pounds with metal construction, this machine accepts USB design transfers in DST and JEF formats, while AcuFil technology maintains smooth fabric feeding across curved cap surfaces.

You’ll find automatic thread trimming and compatible cap frames simplify production, though you should verify compatibility with your computer’s operating system before purchase to avoid connectivity frustrations.

| Best For | Serious embroiderers and small business owners who need commercial-grade capacity for hat customization and high-volume projects. |

|---|---|

| Brand | Janome |

| Weight | 64 pounds |

| Primary Use | Multi-needle embroidery |

| Color | Multicolor |

| Material | Metal |

| Skill Level | Hobbyist to professional |

| Additional Features |

|

- 15-needle setup eliminates constant thread swaps on multicolor designs

- 20″ x 14″ embroidery area handles oversized patterns and cap frames easily

- USB transfer supports DST and JEF files for flexible design options

- Some units arrive refurbished or with quality issues like broken needles

- MAC compatibility problems reported by multiple users

- 64-pound weight makes repositioning difficult without help

Key Features to Consider in Hat Stitching Machines

Choosing the right hat stitching machine isn’t just about price—it’s about matching specific technical capabilities to your production needs, whether you’re running a small custom shop or scaling up to commercial volume. The machines we’ve reviewed vary markedly in needle configuration, embroidery capacity, design flexibility, and automation levels, so understanding these core features will help you make a confident purchase decision.

Let’s break down the critical specifications you need to evaluate before investing in your next embroidery machine.

Multi-Needle Vs. Single-Needle Capabilities

Your needle configuration shapes everything from thread management to production speed on hat embroidery. Multi-needle embroidery machines use four to sixteen needles for automatic color sequencing, eliminating manual swaps and boosting embroidery efficiency on complex cap designs. Single-needle systems require operator intervention between colors but offer simplicity for basic lettering.

Multi-needle setups deliver higher stitch quality and consistent tension across color changes, while single-needle machines suit smaller runs with fewer hues. For an in-depth breakdown comparing, consider how project complexity and scale impact your choice.

Embroidery Area and Hooping Systems

Your embroidery area determines whether you can tackle sprawling multi-panel designs or limit yourself to compact monograms on hats. Look for embroidery machines with 5×7 inch hoops for flexibility, cap frames designed to secure curved brims without distortion, and stabilizer types matched to knit fabrics.

Consider these essentials:

- Hoop sizes from 4×4 to 6×10 inches for varied embroidery fields

- Magnetic or scroll hoops to minimize fabric compression

- Adjustable cap frames with height settings for different hat depths

When selecting a machine, understanding the differences between is essential for achieving the best design results.

Built-in Designs and Customization Options

Your machine’s design libraries release creative potential—built-in designs range from 50 to 300+ motifs optimized for cap curvature, while font options support multiple alphabets with sizing adjustments for crown shapes. Custom uploads via USB or wireless transfer let you load proprietary logos without external editing software, and machines with 6-10 thread colors deliver multi-hued embroidery patterns in single runs.

| Feature | What to Look For |

|---|---|

| Built-in Designs | 100-300 hat-optimized patterns including logos, florals, text |

| Font Options | Multiple alphabet styles with adjustable sizing for curved surfaces |

| Custom Uploads | USB/wireless transfer for proprietary designs without external editing |

| Editing Software | On-screen customization and personalization tools for design modification |

| Thread Colors | 6-10 needle setups for complex multi-color embroidery without rethreading |

Speed and Automation Functions

Speed controls transform production output—variable settings up to 8,500 stitches per minute let you balance precision alignment with throughput, while automatic trimming cuts jump stitches within 0.5 seconds of color changes.

Thread sensors pause operations when breaks occur, and stitch optimization modes reduce faulty stitches by 40 percent, making industrial embroidery machines deliver consistent automated sewing solutions across high-volume hat runs.

Choosing The Right Machine for Your Needs

Selecting the right hat embroidery machine isn’t about chasing the most expensive model—it’s about aligning your investment with your specific production goals, skill level, and budget constraints.

Your decision should balance technical capabilities against practical factors like learning curve, ongoing support, and long-term reliability.

Here’s how to match machine specifications to your operational requirements and confirm you’re making a purchase that drives profitability rather than dust collection.

Matching Machine Features to Project Types

Your project scope directly determines which embroidery machine features you’ll actually use. Consider machine compatibility with different fabric weights, project scaling from single caps to batch runs, and stitch optimization settings that handle dense logos without thread breaks. Design flexibility matters most when clients request complex artwork requiring multiple needle changes or precise kerning adjustments for custom text on curved hat surfaces.

- Single-color team logos on cotton caps need basic single-needle machines with reliable cap frame compatibility

- Multi-color corporate branding across varied hat styles demands multi-needle setups with automatic jump stitch trimming

- High-volume orders for promotional headwear require maximum stitch rates above 800 SPM with sequential color management

- Custom monogramming services benefit from built-in lettering modules and PNG file compatibility for quick personalization

Budget Considerations for Commercial Use

Financial projections for commercial use start with capital equipment depreciation spread over 5 to 7 years, ensuring accurate budget planning.

When reviewing embroidery machine specifications for small business operations, factor in lease costs consuming up to 40 percent of monthly expenses, plus material price fluctuations of 12 to 18 percent seasonally.

Investment strategies should reserve 3 to 5 percent of revenue for insurance and compliance through consistent expense tracking.

Ease of Use and User Skill Level

Once you’ve locked down your budget, matching the learning curve to your skill level keeps frustration at bay and protects your investment from operator error.

Beginner-friendly embroidery machines let first-time users complete a hat project within 20 minutes using guided tutorials, while on-screen prompts simplify thread selection and reduce setup time by up to 40 percent.

- Auto hooping and cap frame presets eliminate guesswork during initial setup

- Built-in help menus deliver step-by-step fixes for common hat embroidery issues

- Real-time stitch monitoring alerts you to bobbin breakage with audible and visual cues

- Quick-start guides include a 9-step checklist from power-on to finishing your sample

- Self-check routines verify temperature and lubrication specs before each session

Brand Reputation and Support

A strong warranty and responsive support channels separate reliable embroidery machine brands from fly-by-night suppliers—Brother PE800 and Janome MB4S consistently earn high marks in embroidery machine reviews for 24/7 phone assistance and transparent replacement-parts guarantees.

Customer reviews reveal that brand loyalty grows when manufacturers honor warranty options without hassle, making trust factors like independent third-party certifications critical to your sewing and embroidery investment.

Essential Accessories for Hat Embroidery

Even the best hat embroidery machine won’t deliver professional results without the right accessories backing it up. From stabilizers that prevent puckering to specialty needles designed for curved surfaces, these supporting tools determine whether your embroidered caps look polished or poorly executed.

Here’s what you need to stock your workspace for consistent, commercial-quality hat embroidery.

Stabilizers and Backing Materials

Backing materials determine whether your hat designs stay crisp or distort after the first wash. Tearaway stabilizers, usually 1.5 to 2 ounces per square yard, work well for stable fabrics and quick production, while cutaway options at 2.5 to 3.75 ounces provide long-term dimensional stability on stretchy materials.

Cap backing, designed at three ounces, maintains fabric tension on curved surfaces and prevents sinking into the needle throat.

Adhesive materials simplify hooping for collars and specialty placements, giving you hoop-free embroidery support when traditional frames won’t work.

Specialty Needles for Hats

You won’t achieve professional hat embroidery without matching needle types to your fabric. Embroidery needles sized 75 to 90 balance thread compatibility with cap surface penetration, while milliners needles, ranging 2 to 4 inches, handle pleating and decorative stitching around curved brims.

Titanium-coated options extend lifespan in high-volume production, and barbed felting needles prevent fiber tearing during specialty hat customization techniques.

Thread Selection for Durability

Polyester thread delivers exceptional tensile strength and resists abrasion on curved cap seams, while nylon offers tear resistance that prevents knot slippage during embroidery machine operation.

Core spun threads combine a polyester core with cotton wrap for enhanced sheen and colorfastness, maintaining stitch integrity after repeated washing.

You’ll need colorfast, heat-compatible threads paired with your stabilizer to prevent dye migration and guarantee material compatibility across sewing and embroidery applications.

Cap Frames and Hoops

Cap Frame Mechanics transform how your embroidery machine manages curved surfaces, with three-point grip systems securing front panels and sweatbands for precise embroidery registration. Gen 2 HoopTech frames, compatible across Tajima and ZSK brands, let you stitch closer to the bill through redesigned clamps and bill retaining straps.

Consider these essentials for hat embroidery:

- Stainless steel construction for durability in daily production

- Adjustable tensioning mechanisms adapting to fabric thickness

- T-bar framing gages ensuring repeatable stitch accuracy

Maintenance Tips for Hat Stitching Machines

Your hat stitching machine represents a significant investment, and proper maintenance is what separates a five-year lifespan from a fifteen-year one.

Regular care prevents costly downtime, ensures consistent stitch quality, and protects the precision components that make professional embroidery possible.

Here’s what you need to know about keeping your machine running at peak performance.

Cleaning and Lubrication Best Practices

You can’t afford to skip daily maintenance if you want your embroidery machines for hats to run smoothly under commercial pressure. Use lint-free brushes to clear thread debris from the bobbin area and needle plate after each shift, then apply manufacturer-specified lubricant types to metal bushings and hook assemblies.

Establish cleaning schedules that include weekly deep cleans of thread paths, cap frames, and embroidery arm components to prevent stitch quality degradation during hat embroidery runs.

Troubleshooting Common Hat Embroidery Issues

Thread Breakage and Fabric Distortion are early warning signals that tension or stabilizer choice needs immediate adjustment. Set upper tension to 4 and bobbin to 2 for most cotton hats, then run a single stitch test before full production to verify Stitch Quality and prevent Embroidery Errors.

Machine Calibration should follow every needle change or thread weight switch to maintain consistent Hat Embroidery results.

Maximizing Machine Longevity for Commercial Use

Beyond troubleshooting, your commercial embroidery machine maintenance strategy determines profit margins. Implement Preventive Maintenance every 200 hours, focusing on Machine Calibration and Wear Part Management to achieve Downtime Reduction.

Operator Training on threading, hooping, and needle changes prevents 70% of industrial embroidery failures. Rotating service schedules reduce thermal stress on embroidery machine for commercial use components, extending lifecycles and maximizing return on investment.

Frequently Asked Questions (FAQs)

What brands of embroidery machines are best?

Which embroidery machine brand truly delivers? Brother and Janome lead in machine reliability and customer support, offering strong product warranty coverage, while Baby Lock and Bernette follow market trends with cutting-edge features for diverse embroidery needs.

What is the cost of Tajima 6 head embroidery machine?

New Tajima 6-head embroidery machines start around twenty-five thousand dollars, while refurbished models range from eight thousand to forty thousand dollars.

Automation features, needle count, and installation costs greatly affect your final purchase price.

What machine does Lids use for hats?

When you walk into Lids for hat customization, you’ll find their staff operating commercial multi-head embroidery machines designed specifically for cap decoration.

These machines use computer-controlled systems that store design files for quick, precise hat embroidery across various cap styles.

What is a good embroidery machine for hats?

A good embroidery machine for hats features cap frame compatibility, multi-needle capabilities for low thread breakage, and post bed machines designed for curved surface stitching.

The Brother PE800 and Janome MB-7 offer reliable hat and cap customization options.

Is a hat embroidery business profitable?

Yes, hat embroidery businesses can achieve profit margins from 20 to 60 percent when you refine cost analysis, leverage custom hats demand, and establish revenue streams through corporate branding and wholesale partnerships.

Who makes the best embroidery sewing machine?

Brother leads the market with adaptable embroidery machines like the PE800, while Janome excels in multi-needle systems and Bernina delivers premium stitch quality—each brand comparison reveals distinct strengths in machine quality and sewing features.

What is the best needle for embroidery hats?

For most hat embroidery, you’ll want a sharp 75/11 or 80/12 embroidery needle, with titanium-coated options delivering exceptional stitch quality and longevity when running high embroidery speed projects on your embroidery machine.

Do you need a special embroidery machine for hats?

Not every cap stitching technique setup works—you need cap embroidery machine hooping systems and multi-needle capabilities for curved surface embroidery.

Additionally, dedicated hat embroidery basics like stabilized frames are essential, since standard embroidery machines lack proper hat decoration methods for structured crowns.

What is the best embroidery size for a hat?

For structured baseball caps, your embroidery design should measure 0 to 5 inches tall on the front panel.

Low-profile hats work best with 75 to 0 inch designs to maintain proper proportion and thread visibility.

Can you make money embroidering hats?

Like planting seeds in fertile soil, hat embroidery yields profit margins from 6 to 40 percent, with bulk orders pushing earnings above $5 per hat when you balance embroidery costs, market demand, and pricing strategies effectively.

Conclusion

Your hat embroidery business will live or die by the machine you choose—there’s simply no middle ground when curved surfaces exaggerate every mechanical flaw.

The 5 best hat stitching machines we’ve reviewed deliver the multi-needle precision, sturdy hooping systems, and tension control that separate profitable production from costly rework.

Match your project volume to machine capabilities, invest in proper stabilizers and cap frames, then maintain your equipment religiously to protect what becomes your shop’s revenue engine.