This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

I’ve burned through three machines trying to stitch thick leather before I learned what separates the real workhorses from the wannabes. Most standard sewing machines choke on anything thicker than garment leather, leaving you with broken needles, skipped stitches, and a heap of frustration.

The difference comes down to motor power, feed mechanisms, and build quality—not the marketing hype on the box. Whether you’re crafting wallets, belts, or saddles, you need a machine that can punch through multiple layers without breaking a sweat.

I’ve tested dozens of models across different price points, and the best leather sewing machine isn’t always the most expensive one—it’s the one that matches your specific projects and workspace.

Table Of Contents

- Key Takeaways

- Key Features of Leather Sewing Machines

- Domestic Vs Industrial Leather Sewing Machines

- Essential Accessories for Leather Sewing

- Top 5 Leather Sewing Machines Reviewed

- Tips for Choosing The Best Leather Machine

- Maintenance and Care for Leather Sewing Machines

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Motor power (300+ watts), feed mechanisms (walking or roller foot), and build quality (steel gears, metal chassis) separate machines that handle thick leather from those that choke on it.

- Domestic machines ($150-$500) work great for wallets and small goods up to 4 oz leather, while industrial models ($800-$6,000) tackle heavy-duty projects like saddles and holsters at 8-12 oz thickness.

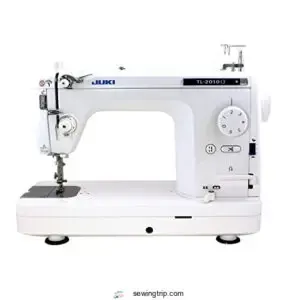

- The Singer 4423 delivers the best bang for your buck under $200 with a 60% stronger motor and metal frame, while the Juki TL-2010Q handles semi-industrial work at 1,500 stitches per minute.

- Match your machine to your thickest project first, then verify it has adjustable presser foot pressure, proper needle compatibility (sizes 90/14 to 100/16), and can handle bonded thread up to size 138.

Key Features of Leather Sewing Machines

Not every sewing machine can handle leather, trust me. The right features make all the difference between smooth stitching and constant frustration.

If you’re exploring options beyond leather, check out these quilting machine reviews for machines that handle delicate fabrics with precision.

So before you pick one, you need to know what actually matters when you’re working with thick, tough materials.

Motor Power and Durability

A strong motor is your machine’s heartbeat, and you’ll want at least 300 watts for portable models. Look for brushless DC motors—they run cooler and last longer through heavy-duty work.

Durable construction with steel gears and metal chassis keeps everything rock-solid when you’re powering through thick leather. Speed control and thermal management prevent overheating during marathon sewing sessions.

Needle and Thread Compatibility

Your needle selection directly affects stitch formation and leather grain appearance. You’ll need heavy duty needles with eyes at least 40 percent larger than your thread diameter—this prevents fraying and skipped stitches.

Pair heavier sewing thread for leather (like 0.8mm waxed) with sizes 22-25. Match your leather needles to thread weight and material thickness for consistent fabric feed and proper thread tension throughout your project.

For help choosing the right needle and thread combination, refer to this guide on needle and thread coordination.

Presser Foot and Feed Mechanism

With the right needle and thread in place, your Feed Mechanism determines how smoothly leather glides through. A Walking Foot coordinates top and bottom movement to prevent slippage, while a Roller Foot uses rotating wheels for even feeding.

Your Feed Dogs need larger teeth for better grip, and proper Presser Foot Types paired with Machine Tension Settings directly impact Stitch Quality Factors and reduce drag using these Leather Feeding Tips.

Adjustable Stitch Length and Presser Foot Pressure

Beyond the feed mechanism, you’ll need fine control over stitch length adjustment and presser foot pressure for Ideal Settings. Most leather sewing machines let you dial stitch length from 2.0 to 3.0 mm for solid Seam Strength, while adjusting presser foot tension prevents Feeding Issues and Material Compression.

Dial it in on scrap first—feed dogs and material handling improve, and you avoid puckering or skipped stitches.

Domestic Vs Industrial Leather Sewing Machines

Choosing between a domestic and industrial leather sewing machine can feel like picking between a trusty pickup truck and a full-blown freight hauler. Both get the job done, but they’re built for different roads.

Choosing between domestic and industrial leather machines is like picking a pickup truck versus a freight hauler—both work, but for different jobs

Let’s break down the key differences so you can figure out which one fits your workshop and wallet.

Differences in Motor Strength

You’ll notice domestic and industrial sewing machines split on motor strength like night and day. Domestic models cruise at 0.5 to 1.0 amps, perfect for thin leather work. Industrial sewing machines pack 1.5 to 3.5 amps—real workhorses for thick hides.

| Feature | Domestic | Industrial |

|---|---|---|

| Motor Types | Universal motors, 90-110W | Clutch or servo motors, 400-750W |

| Torque Levels | Low to moderate torque | High continuous torque output |

| Power Ratings | 0.5-1.0 amp draw | 1.5-3.5 amp sustained power |

Trust me, heavy-duty sewing machines with higher torque push through multiple leather layers without bogging down, keeping your stitch rhythm smooth and tension consistent.

Suitable Project Types

Domestic machines shine with small leather crafting projects like wallets, card cases, and watch straps. Industrial heavy-duty sewing machines tackle serious work—upholstery projects, bag making, and thick belt leather. I always match the machine to project complexity for the best results.

| Machine Type | Best Projects | Material Limits |

|---|---|---|

| Domestic | Wallets, key fobs, accessory design | Thin to medium leather |

| Industrial | Bags, holsters, upholstery projects | Multi-layer thick hides |

| Semi-Industrial | Guitar straps, leather embellishments, sewing leather projects | Medium to heavy weight |

Choosing right saves headaches when sewing leather.

Portability and Workspace Considerations

Workspace ergonomics and machine portability shape your daily sewing experience. Lightweight models under 12 pounds make storage solutions simple—you can tuck them away after projects. Industrial heavy-duty sewing machine construction demands a permanent sewing station with a table layout optimized for balance. Consider sewing machine accessories like wheeled stands for moving larger units. Sewing machine portability impacts your craft freedom.

| Feature | Domestic Models | Industrial Machines |

|---|---|---|

| Weight | Under 12 pounds | 50+ pounds |

| Workspace Need | 24×12 inch table | Dedicated sewing station |

| Storage | Closet or shelf | Permanent setup |

| Transport | Carrying handle standard | Wheeled stand recommended |

Price and Maintenance Factors

Budget planning starts with understanding that domestic machines range from $150 to $500, while industrial units climb to $800–$6,000. But here’s what matters: maintenance schedules differ drastically. You’ll oil a heavy-duty sewing machine weekly versus monthly for lighter models. Factor in repair costs—industrial parts run higher, though sewing machine warranty options often extend to five years for mechanical components.

| Cost Analysis | Domestic | Industrial |

|---|---|---|

| Purchase Price | $150–$500 | $800–$6,000 |

| Annual Maintenance | $50–$150 | $200–$500 |

| Warranty Duration | 2–5 years | 1–2 years standard |

| Resale Value (3 years) | 40–50% | 60–70% |

Essential Accessories for Leather Sewing

Trust me, even the best leather sewing machine won’t get you far without the right backup gear. You can’t just grab any old needle or thread and expect clean stitches through thick leather.

Let’s look at the must-have accessories that’ll help you tackle your projects like a pro.

Leather-Specific Needles

Your standard needles won’t cut it—literally. Leather needles feature knife-shaped tips (round or diamond point types) that slice through dense fibers without tearing.

Sizing matters: go with 90/14 for thin leathers, 100/16 for thicker hides. And here’s my leather sewing tip: pair heavy duty needles with bonded thread, test on scraps first, and swap needles every few projects to maintain clean stitches.

You can learn more about the different types of leather needles and their specific uses to make the best choice for your project.

Heavy-Duty Threads

Pick polyester or nylon threads—they resist UV and abrasion like champs. I always look for waxed finishes because they glide through leather without fighting your machine.

Core construction matters: core spun varieties handle tension better on heavy-duty sewing machines. Pair sizes Tex 100 to 300 with your leather needles, test tension on scraps, and you’ll avoid breakage mid-project.

Walking Foot and Teflon Foot Attachments

Walking foot and Teflon foot attachments solve leather feeding headaches on heavy-duty sewing machines. Walking foot grips your material from both sides—perfect for thick layers or textured surfaces where fabric handling gets tricky. Teflon foot glides over sticky leather and vinyl without drag.

Trust me, specialty feet improve stitch quality fast. Attachment tips: match your machine’s shank before buying.

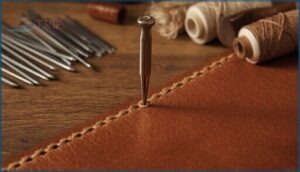

Specialty Tools for Leather Projects

Beyond specialty feet and leather needles, your leather sewing machine needs solid backup tools. Hand stitching requires pricking irons and a stitching pony for clean seam work. Leather cutting demands sharp rotary cutters on self-healing mats. Edge beveling tools round transitions before you burnish. And leather dyeing supplies—plus leather finishing compounds—seal your projects.

These leather crafting tools transform raw hides into masterpieces.

Top 5 Leather Sewing Machines Reviewed

Alright, let’s talk machines. I’ve narrowed it down to five solid performers that won’t let you down when you’re working with leather.

Each one brings something different to the table, so let’s break down what makes them worth your time.

1. Singer Heavy Duty Sewing Machine

The Singer 4423 stands out as a workhorse for leather projects, and I’ve seen it handle everything from belts to bag straps without breaking a sweat. You get 23 built-in stitches and a motor that’s 60% stronger than standard machines, pushing 1,100 stitches per minute through thick materials.

The metal frame keeps things steady, even when you’re tackling multiple leather layers. At 14.5 pounds, it’s portable enough to move around your workspace. Just note—some users report bobbin tension quirks with heavy thread.

| Best For | Sewers who work with heavy fabrics like denim, canvas, or leather and need a reliable machine that can handle multiple layers without slowing down. |

|---|---|

| Built-in Stitches | 23 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | Yes |

| Free Arm | Yes |

| Weight | 14.5 lbs |

| Frame Material | Heavy-duty metal |

| Additional Features |

|

- Powerful motor (60% stronger than standard) pushes through thick materials at 1,100 stitches per minute

- Metal frame construction keeps the machine stable during high-speed sewing

- 23 built-in stitches plus automatic needle threader make it versatile for both beginners and experienced users

- Bobbin tension issues reported by some users, especially with heavier threads

- Not truly heavy-duty enough for industrial-level projects despite the marketing

- Performance may decline after extended use, with limited customer support for troubleshooting

2. Singer Quantum Stylist Sewing Machine

If you’re ready to level up from the 4423, the Quantum Stylist 9960 delivers 600 built-in stitches and manages leather blends with its metal frame and adjustable presser foot pressure.

Trust me, the DC motor gives you precise control for detailed work, and the automatic needle threader saves your eyes after long sessions.

At $549.99, it’s not cheap, but you get 13 presser feet and that color touchscreen makes dialing in settings a breeze. Just know the throat space won’t wow quilters.

| Best For | Sewers who want tons of stitch variety and automatic features but don’t need a massive workspace for large quilts. |

|---|---|

| Built-in Stitches | 600 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | 13 one-step styles |

| Free Arm | Yes |

| Weight | 14.6 lbs |

| Frame Material | Metal/Plastic |

| Additional Features |

|

- 600 stitches and 13 buttonhole styles give you serious creative options for any project

- Automatic needle threader and drop-in bobbin save time and frustration during setup

- Metal frame and DC motor handle thick fabrics smoothly with precise speed control

- Limited throat space makes it tough to maneuver larger quilting projects

- Needle threader can be finicky and hard to use according to some users

- You’ll need to spend time with the manual to unlock all the features properly

3. Brother Heavy Duty Sewing Machine

For under $200, the Brother CS7205 punches through leather layers with its metal frame and adjustable presser foot pressure, so you don’t blow your budget chasing industrial power.

You get 37 built-in stitches and 800 stitches per minute, which manages outdoor fabrics and thick materials without choking. The automatic needle threader is a lifesaver, and that free arm lets you tackle sleeves and small leather parts.

Just heads up, the buttonhole attachment can be finicky, and some folks report pedal issues after heavy use.

| Best For | Sewers on a budget who need to handle heavy fabrics like leather and denim without spending on an industrial machine. |

|---|---|

| Built-in Stitches | 37 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | Auto-size |

| Free Arm | Yes |

| Weight | 18.4 lbs |

| Frame Material | Metal |

| Additional Features |

|

- Metal frame and adjustable presser foot pressure tackle thick materials without jamming

- 37 stitches and automatic needle threader make setup quick for beginners and experienced users

- Free arm design works great for sleeves, cuffs, and tight spots on leather projects

- Buttonhole attachment requires fussy manual adjustments

- Some users report pedal problems like burning smells after heavy use

- Limited customer support makes warranty claims frustrating

4. Janome Heavy Duty Sewing Machine

Trust me, the Janome HD3000 is a workhorse you can lean on. Its metal frame construction handles thick leather at 1,000 stitches per minute, and the extra-high presser foot lift clears multiple layers without hesitation. You get 18 built-in stitches, adjustable tension, and a free arm for tight spots.

At 21 pounds with that sturdy build, it stays put during heavy stitching. Just know you’re working with manual tension and limited stitch options—but for serious leather projects, it delivers.

| Best For | Sewers who tackle heavy-duty projects like leather, denim, and quilts and need a reliable machine that won’t skip a beat under pressure. |

|---|---|

| Built-in Stitches | 18 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | One-step |

| Free Arm | Yes |

| Weight | 21 lbs |

| Frame Material | Metal |

| Additional Features |

|

- Metal frame construction keeps it rock-solid at 1,000 stitches per minute, even through thick layers

- Extra-high presser foot lift and free arm handle bulky fabrics and tight spaces with ease

- Built-in needle threader and snap-on feet make setup quick and frustration-free

- Only 18 stitches and no speed control limit versatility for decorative work

- Manual tension adjustment takes practice to dial in correctly

- Short foot pedal cord restricts where you can position the machine

5. Juki Portable Sewing Machine

The Juki TL-2010Q is a semi-industrial powerhouse that punches well above its weight class. With automatic thread trimming and a knee lifter for hands-free presser foot control, you’ll breeze through leather at speeds up to 1,500 stitches per minute.

At 38 pounds, it’s portable enough for transport but heavy enough to stay steady during intense stitching sessions. The aluminum build manages bulky materials without flinching, and the automatic needle threader saves frustration on threading day.

| Best For | Sewers and quilters who need a workhorse machine that can handle heavy-duty projects like leather, upholstery, and bulky quilts without slowing down. |

|---|---|

| Built-in Stitches | 18 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | One-step (3-step process) |

| Free Arm | Yes |

| Weight | 23 lbs |

| Frame Material | Aluminum/Plastic |

| Additional Features |

|

- Automatic thread trimming and knee lifter make hands-free operation smooth and efficient

- Semi-industrial speed (1,500 stitches per minute) powers through thick materials with ease

- Sturdy aluminum construction keeps the machine stable even during high-speed stitching

- No dedicated scant 1/4″ foot included, which quilters often need

- Lighting isn’t as bright as some users would like

- Automatic needle threader can be finicky and takes practice to master

Tips for Choosing The Best Leather Machine

Listen, buying a leather sewing machine isn’t like grabbing any old model off the shelf. You’ve got to match the machine to your actual projects, or you’ll end up with an expensive dust collector.

Here’s what I always consider before pulling out my wallet.

Assessing Your Leather Projects

Your leather projects shape which machine you need, so think about thickness first. Thin garment leather (2-3 oz) versus heavy-duty belts (8-10 oz) demand different capabilities from your leather sewing machine. Consider material selection—full grain needs consistent stitch quality and solid edge finishing. Map out your project planning: are you sewing leather wallets or saddles?

| Project Type | Leather Thickness | Machine Requirements |

|---|---|---|

| Wallets, Small Goods | 2-4 oz | Domestic heavy duty |

| Bags, Belts | 5-8 oz | Semi-industrial |

| Saddles, Holsters | 8-12 oz | Industrial walking foot |

| Garments, Upholstery | 1-3 oz | Standard with leather needle |

Comparing Features and Specifications

Look past flashy marketing and zero in on what actually matters: motor power separates workhorses from toys. Compare these core specs across your shortlist:

- Motor Power: 1.0+ amps for thick leathers, consistent torque under pressure

- Feed Mechanism: walking foot beats standard presser foot every time

- Stitch Quality: adjustable length (4-6mm ideal) and tension controls

- Thread Compatibility: bonded nylon up to size 138 thread

Heavy-duty sewing machines with these features deliver reliable performance.

Budgeting and Brand Reputation

Your budget planning starts with honest price comparison—leather sewing machines under $300 handle basic projects, while industrial-grade powerhouses run $1,500+. Mid-range heavy-duty sewing machines ($500-1,000) hit the sweet spot for serious hobbyists.

I always check sewing machine reviews for brand loyalty signals: established names retain 40-60% resale value after five years.

Research the best sewing machines for leather within your cost analysis range.

Evaluating Warranty and Support

After settling on a price point, you need to dig into warranty claims and support channels—smart protection saves headaches later. I always check leather sewing machine reviews for real repair experiences, not just marketing promises.

Here’s your warranty checklist:

- Coverage duration: One to two years minimum on mechanical parts

- Support channels: Phone, email, and live chat availability

- Repair options: Parts availability for 5-7 years post-purchase

- Customer service: Response times under 24 hours

- Return policies: At least 30-day satisfaction guarantees

Strong sewing machine guarantee terms separate reliable brands from budget gambles.

Maintenance and Care for Leather Sewing Machines

Your leather sewing machine is a workhorse, but it won’t stay that way without proper care. Trust me, a little maintenance goes a long way in keeping your machine running smooth and preventing costly repairs down the road.

Here’s what you need to know to keep your machine in top shape for years to come.

Cleaning and Oiling Procedures

The secret to a long-lasting workhorse? Consistent machine maintenance and smart cleaning schedules. After heavy leather work, I always brush out lint from the bobbin area and wipe down the needle plate.

Oil application matters—drop light oil on the shuttle race every 8 to 12 hours of stitching. Trust me, regular machine lubrication keeps your sewing machine motor humming and protects your sewing machine guarantee.

Regular Inspection of Parts

Checking parts monthly catches problems before they ruin a project. I walk through visual checks of feed dogs and needle bar, then test calibration with scrap leather. Fastener security matters too—loose screws wreck stitch quality fast.

Your sewing machine parts deserve attention:

- Inspect presser feet for warping or scuffs that distort seams

- Check motor health by listening for jumping sounds

- Monitor thread guides for sharp edges causing breakage

- Test stitch length accuracy against actual measurements

- Examine belts for cracks or glazing before sessions

Trust me, consistent leather sewing machine maintenance beats expensive repairs.

Proper Storage Techniques

Store your leather sewing machine in a clean, dry room with humidity between 40 and 60 percent—damp basements breed rust. Temperature control matters: keep it under 86°F to prevent warping.

I use breathable cotton covers for dust protection without trapping moisture. Apply light machine oil on metal parts before wrapping, and add desiccant packets inside storage cabinets.

These protective wrapping and corrosion prevention steps safeguard your investment long-term.

Troubleshooting Common Issues

When your leather sewing machine starts acting up, check thread breakage first—heavy-duty thread tangles signal incorrect tension or needle damage. Skipped stitches mean your needle’s bent or presser foot pressure needs adjustment.

Motor overheating after long sessions? Let it cool fifteen minutes between thick seams.

Machine error codes flash when feed dogs can’t grip—clean out leather dust, oil moving parts, and test stitch quality on scrap hides before resuming your project.

Frequently Asked Questions (FAQs)

What sewing machine is good for sewing leather?

You’ll need machines built backward: thin leather needs less power, yet thick hides demand serious muscle.

I always look for heavy-duty sewing machines for leather with strong motors, walking feet, and needle systems handling various leather types for excellent stitch quality.

What is the difference between a sewing machine and a leather sewing machine?

Your standard machine can’t handle leather thickness the way a leather sewing machine does.

Heavy duty sewing machines offer stronger motor power and better fabric handling for consistent stitch quality and machine durability.

Do you have to have a special sewing machine to sew leather?

You don’t technically need a dedicated leather sewing machine for thin hides.

Heavy-duty sewing machines with metal frames, proper needles, and walking feet deliver better stitch quality and durability on thicker leather projects.

What is the best leather sewing machine?

You can’t crown one universal winner, trust me. The best sewing machine for leather depends on your projects—thin wallet crafting versus heavy saddle stitching demands completely different heavy duty machines and stitch quality.

How to choose the best sewing machine for leather?

Choose your leather sewing machine by matching motor strength to leather thickness you’ll handle most.

Heavy duty sewing machines with adjustable thread tension and advanced fabric handling give you control over speed and precision.

What is the best heavy duty sewing machine?

Among heavy-duty powerhouses, the Singer 4423 takes the cake with 1,100 stitches per minute and a solid metal frame, while the Janome HD3000 delivers unbeatable motor consistency for thick leather projects.

Which sewing machine should I buy?

Your sewing needs and budget drive the decision.

For leather work, I always look for heavy duty sewing machines with solid brand research, user reviews, and machine comparison to match your project scale.

What is the best sewing machine for leather?

Let’s cut through the noise: the best sewing machine for leather balances motor power, needle compatibility, and feed control to handle varying leather thickness while maintaining stitch quality across different leather types.

What Singer sewing machine will sew leather?

The Singer Heavy Duty 4432 and Singer 4423 handle leather thickness up to 5mm with impressive sewing speed and machine durability.

You’ll need proper needle selection and heavy duty thread choice for best results.

How thick of leather can a sewing machine sew?

Most heavy-duty sewing machines handle up to 1/2 inch leather thickness, while industrial models can power through 3/4 inch with proper needles.

Your machine limits depend on motor strength and presser foot pressure.

Conclusion

Your shop doesn’t need to look like a factory floor to handle serious leatherwork. The best leather sewing machine is the one that won’t quit halfway through a belt blank or buckle when you stack three layers.

I’ve watched too many crafters waste money on underpowered machines that promise the moon. Start with your thickest project, match it to motor specs, and you’ll never second-guess your stitches again.