This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Choosing the best leather sewing machine means focusing on power, precision, and durability. You’ll need a heavy-duty motor to handle thick materials and strong feed dogs to guarantee smooth fabric movement.

Choosing the best leather sewing machine means focusing on power, precision, and durability. You’ll need a heavy-duty motor to handle thick materials and strong feed dogs to guarantee smooth fabric movement.

Machines like the Singer Heavy Duty 4452 or the Janome HD3000 are excellent; they’re built tough and handle leather with ease.

Look for features like adjustable stitch length, a walking foot, and leather-piercing needles for better control. If you work with thicker leathers, a dedicated walking foot machine is ideal.

It’s all about finding the right tool for the job—because using the wrong machine can leave you in stitches (literally).

Table Of Contents

- Key Takeaways

- Choosing The Best Leather Sewing Machine

- Essential Criteria for Leather Sewing Machines

- Top 6 Best Leather Sewing Machines

- Key Features of a Good Leather Sewing Machine

- Tips and Techniques for Sewing Leather

- Maintaining and Operating Leather Sewing Machines

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Focus on machines with strong motors, walking feet, and adjustable presser foot pressure for smooth handling of leather projects.

- Choose the right needle and thread pairing, like leather-piercing needles and bonded nylon thread, to guarantee clean and durable stitches.

- Practice on scrap leather to fine-tune your tension settings, stitch length, and technique before starting a full project.

- Keep your machine well-maintained with regular cleaning, lubrication, and adjustments to ensure long-lasting, consistent performance.

Choosing The Best Leather Sewing Machine

Choosing the right leather sewing machine depends on your budget, experience, and project needs.

It’s important to take into account leather thickness, machine features, and whether a walking foot is essential for handling heavier materials, considering these factors will help in selecting the right machine for your specific project needs.

Determining Your Budget and Sewing Experience

Choosing the right leather sewing machine starts with clear Budget Allocation and a honest Skill Level assessment.

Leather sewing machine costs vary widely—expect industrial models to range from $1,000 to $12,000, while second-hand machines might fit under $600. Start by asking yourself: "What scope of projects will this machine handle?"

For beginners, a more affordable sewing machine for beginners or second-hand heavy-duty option might better balance budget and Future Needs.

Even within the sewing machine price range for professionals, focus on features that match your experience.

- Pro Tip: If you’re new, opt for an entry-level leather sewing machine. Many budget picks, like manual cobbler machines, offer durability for practice.

Remember, your machine should scale with your skills. Evaluate machine lifespan and upgrade later based on growing expertise!

Many users find a walking foot invaluable for consistent stitching.

Considering The Thickness and Type of Leather

When working with leather, understanding its thickness and type is essential to picking the right sewing machine.

Master leather sewing by matching machine features to material thickness—precision and durability are the keys to standout projects.

From thin suede to thick full-grain leather, each material demands specific features.

For lighter leather, a standard heavy-duty machine may do, but medium or thick leather often calls for walking foot machines or industrial options.

Heavy upholstery or harness leather? You’ll need a sewing machine for thick fabrics with industrial strength.

Always check the maximum thickness a machine can handle before diving into a project.

Features like adjustable tension and leather sewing needles are a must for smooth stitching.

Pay attention to grain considerations and tannage methods—these affect how the leather behaves under the needle.

Don’t skimp on these details for better results!

Features to Look for in a Leather Sewing Machine

A great leather sewing machine stands out with specific features.

Prioritize strong feed dogs to easily guide materials without sticking and guarantee stitch precision. Look for adjustable presser foot clearance to handle varying leather thicknesses.

Needle piercing power is critical—choose machines that support leather needles for smooth penetration through thick fabrics. Opt for a servo motor for consistent power and precise speed control.

Durable frames enhance stability during heavy-duty sewing. These sewing machine features simplify leather sewing techniques while improving durability, making them essential in your sewing machine buying guide for thick fabrics, with a focus on leather sewing techniques.

Dedicated Walking Foot Machines for Heavier Leathers

Tackling heavy leather projects can feel intimidating without the right tools, but a dedicated walking foot sewing machine changes everything.

Its unique mechanism guarantees the fabric moves evenly, preventing skips and uneven stitches, even with challenging materials.

Here are some top picks for heavy leather stitching:

- Juki DNU-1541S: Handles multiple leather layers effortlessly with precise feed dog strength and superior motor horsepower ratings.

- Consew 206RB-5: Perfect for medium and thick leather, offering exceptional control and leather thickness capacity.

- Reliable 4000SW: Ideal for precision work in upholstery and heavy sewing, delivering consistency at moderate speeds.

Designed to handle tough materials, these industrial sewing machines make mastering leatherwork simple, reducing frustration and improving your results on every project.

Essential Criteria for Leather Sewing Machines

When sewing leather, you need a machine designed to handle its unique challenges, like thickness and stickiness.

Key features such as a heavy-duty motor, strong feed dogs, and specialty presser feet guarantee smooth and precise stitching.

Heavy-duty Motor for Tough Fabrics

A powerful motor is the backbone of any heavy duty sewing machine, especially when you’re tackling leather projects.

Motor power and torque ratings are what allow these machines to pierce through thick, stubborn materials like butter.

Industrial sewing machines stand out here—they handle demanding leatherwork with consistent stitching and impressive speed control.

If you’re serious about the best leather sewing machine, look for models with at least a 1.0 amp motor.

Vibration dampening features also matter, keeping your machine stable and reducing fatigue.

Heavy duty sewing machines designed for industrial applications won’t stall or overheat, making those larger projects manageable.

Regular maintenance guarantees your motor stays reliable for years of smooth, trouble-free leather crafting.

Strong Feed Dogs for Smooth Fabric Movement

To achieve smooth stitches on leather, the feed dogs in your sewing machine play a key role. They grip and guide material for precision, avoiding uneven results.

- Feed Dog Materials: Opt for metal-reinforced ones for durability under pressure.

- Adjustable Feed Dogs: Adapt height smoothly for varying leather thicknesses.

- Feed Dog Maintenance: Keep them clean for consistent performance.

- Feed Dog Angles: Wider spacing prevents bunching, ensuring even stitching.

For superior performance, consider upgrading to durable metal options. With these, leather sewing becomes seamless and frustration-free.

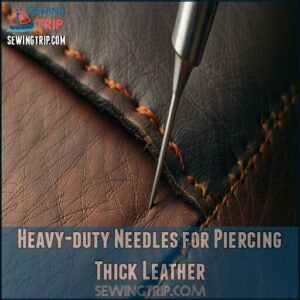

Heavy-duty Needles for Piercing Thick Leather

The right sewing machine needles make or break leather projects.

Leather sewing needles are designed with wedge-shaped points to slice through hides without damage.

For smoother heavy-duty sewing, pair needle sizes with material thickness and thread weight, like this:

Invest in durable needles with strong material composition to prevent needle breakage. To find the right match, you may need to source specialized, durable options. Keep a Needle Size Guide handy for seamless leather sewing machine operation.

Adjustable Stitch Length for Precise Control

Controlling stitch length makes all the difference when working with leather.

Adjustable settings on your leather sewing machine allow you to match the Stitch Length Guide to the project.

Shorter stitches reduce hole sizes, making seams look cleaner on softer leathers. Longer stitches, on the other hand, improve seam strength on thicker materials.

The right sewing machine stitch length lets you balance durability and aesthetics. A good leather stitching machine guarantees smooth performance and professional results, even with varying leather thickness.

For precision and creativity, always prioritize machines offering flexible stitch length options.

Specialty Feet for Better Fabric Handling

Specialty sewing machine feet are an unsung hero in the context of handling leather. These tools make sewing smoother, more precise, and less frustrating, especially with tricky materials.

Using the right leather sewing machine feet guarantees your stitches are even, clean, and professional-looking.

Here are some options to make your sewing more efficient:

- Walking foot – Keeps layers of thick leather aligned by moving the top layer with precision.

- Teflon feet – Non-stick presser feet perfect for gliding over sticky or treated leather.

- Roller feet – Excellent for textured or uneven leather, providing controlled movement.

- Zipper foot – Lets you stitch close to edges or zippers with ease.

- Hemmer foot – Assists in creating neat hems on thin or pliable leather.

Each presser foot solves a specific challenge, revealing new possibilities for your projects.

You can find specialized presser feet designed specifically for leather work.

Top 6 Best Leather Sewing Machines

If you’re searching for a reliable leather sewing machine, understanding the best options can save you time and hassle.

These six highly-rated machines offer the power, durability, and features needed for tackling leather projects with confidence.

1. Singer Heavy Duty Sewing Machine

The Singer Heavy Duty 4423 is a sturdy, high-performing choice for leather projects.

The Singer Heavy Duty 4423 delivers power and precision, making leather projects smooth, efficient, and frustration-free.

With 97 stitch applications, a 60% stronger motor, and a heavy-duty metal frame, it’s built for durability.

Producing up to 1,100 stitches per minute, it guarantees fast results, while the automatic needle threader saves time and effort.

Its clear drop-in bobbin cover simplifies thread tracking, and the included accessories support versatility.

This model also boasts adjustable presser foot for handling different fabric thicknesses.

Once tension is adjusted, this machine effortlessly handles thick leather, producing consistent, professional-quality stitching for your creative projects.

Best For: Beginners and hobbyists looking for an affordable sewing machine that delivers reliable performance for a variety of projects.

- Not suitable for extensive industrial or heavy-duty sewing.

- Automatic threader can be slightly cumbersome to use.

- Considered an entry-level machine with limited durability for intensive use.

- Strong motor and high-speed stitching for quick results.

- Handles thick fabrics like leather and faux leather with ease.

- Includes multiple accessories for versatile sewing needs.

2. Janome HD3000 Heavy Duty Sewing Machine

The Janome HD3000 is like the dependable workhorse every leatherworker needs in their toolkit.

Built with a rugged aluminum frame, this machine provides the reliability you want when working with tough materials. Its 18 built-in stitches cover everything from functional to decorative sewing, keeping things simple yet effective.

The real magic lies in its adjustable presser foot pressure and extra-high lift, letting you handle thick leather layers without a hitch. Plus, the seven-piece feed dog system guarantees your leather feeds smoothly during every stitch.

This isn’t a flashy machine loaded with complex features—it focuses on durability and precision where it counts. Repair jobs, leather accessories, and everyday sewing projects are no sweat for the HD3000. If you value consistency over gadgetry, this machine delivers power, stability, and smooth operation that caters to both casual leather hobbyists and small-scale professionals.

Best For: Beginners, casual leather hobbyists, and small-scale professionals needing a durable, no-frills sewing machine.

- Limited harp space, making it unsuitable for large quilting projects.

- Lacks advanced features like automatic thread cutter or knee lift.

- Not ideal for complex or highly specialized sewing techniques.

- Heavy-duty aluminum frame ensures stability and durability.

- Adjustable presser foot pressure and extra-high lift handle thick materials with ease.

- Top-loading jam-proof bobbin system and smooth feed for consistent stitching.

3. Brother ST371HD Sewing Machine

The Brother ST371HD is a budget-friendly gem for lightweight leather projects, blending versatility and ease of use.

Its 37 built-in stitches and an auto-size buttonhole give you creative freedom, while the automatic needle threader and jam-resistant drop-in bobbin system guarantee smooth operation.

Although not suited for thicker leather, it shines with thinner materials when paired with the right needle.

Equipped with six sewing feet, adding a walking foot enhances leather handling.

Perfect for beginners tackling occasional leather and mixed-material tasks.

Best For: Beginners and intermediate sewists looking for a versatile, budget-friendly machine for lightweight leather and mixed materials.

- Features 37 built-in stitches, including an auto-size buttonhole.

- Automatic needle threader and jam-resistant drop-in bobbin for convenience.

- Compatible with various fabrics, including lightweight leather.

- Not suitable for thicker leather projects.

- Buttonhole function requires manual adjustments.

- Limited compatibility with bobbins from other Brother models.

4. REX Portable Walking Foot Sewing Machine

Combining portability and power, the REX Portable Walking Foot Sewing Machine is a reliable choice for tackling serious leather projects.

With its semi-industrial strength, this machine easily sews through layers of leather, canvas, and heavy upholstery. Its adjustable presser foot pressure guarantees smooth handling, even with trickier materials like velvet (though some minor puckering may occur).

Thanks to its compact design, the REX fits well in smaller spaces while maintaining high performance. It’s perfect for hobbyists or professionals who need a portable yet capable tool.

However, this isn’t a beginner-friendly machine—it requires a good understanding of tension adjustments and material handling for the best results.

The REX stands out for its walking foot mechanism and variable stitch length, which help you take on thick fabrics with ease. While occasional thread tension issues may arise, these are manageable with proper tweaks, making it a solid investment for leather crafters.

Best For: Experienced hobbyists and professionals needing a portable, semi-industrial sewing machine for heavy materials like leather and canvas.

- Handles multiple layers of thick materials with ease.

- Lightweight and portable design for small spaces.

- Adjustable presser foot pressure and variable stitch length.

- Not beginner-friendly, requiring experience with adjustments.

- Minor puckering on delicate fabrics like velvet.

- Occasional thread tension issues that need careful tweaking.

5. Singer Quantum Stylist 9960 Sewing Machine

Delivering versatility and precision, the Quantum Stylist 9960 shines with 600 built-in stitches and 13 one-step buttonholes, perfect for leather projects.

Adjustable speed control—up to 850 stitches per minute—lets you tackle intricate or simple tasks with ease.

Features like the automatic needle threader and top drop-in bobbin system save time during setup.

The extension table, LED lighting, and adjustable presser foot pressure enhance your workspace.

Though quilting limitations exist, its advanced design makes it a reliable, feature-packed tool for leatherworkers.

Best For: Sewing enthusiasts and leatherworkers looking for a feature-packed, versatile machine with advanced functionality.

- 600 built-in stitches and 13 one-step buttonhole styles for creative versatility.

- Automatic needle threader and top drop-in bobbin system for time-saving setup.

- Adjustable speed control and extension table for handling different project types.

- Limited quilting capabilities compared to other machines.

- Difficult bobbin removal after winding.

- Compatibility issues between quilting bar and walking foot.

6. Brother ST150HDH Sewing Machine

Perfect for beginners and intermediate sewers, the Brother ST150HDH is a reliable choice for lightweight leather projects.

Its sturdy metal frame guarantees stability, while the 50 built-in stitches and 7-point feed dogs provide smooth fabric movement.

The walking foot handles multiple leather layers with ease, and the easy-to-read LCD screen removes any guesswork, allowing for excellent control with adjustable stitch length and heavy-duty needles.

Though it’s not ideal for thick leather pieces, it excels at decorative tasks and smaller leather goods.

Best For: Beginners and intermediate sewers working on lightweight leather and fabric projects.

- Sturdy metal frame provides stability and durability.

- Handles multiple layers of heavyweight fabrics like leather and denim.

- LCD screen and advanced needle threader simplify operation.

- Not ideal for thick leather pieces.

- Dim LED light may require additional lighting.

- Sensitive power connector can detach easily.

Key Features of a Good Leather Sewing Machine

When choosing a leather sewing machine, you’ll need features that handle thick, tough materials with precision.

Look for strong needles, durable thread, adjustable stitch length, and sturdy construction to guarantee reliable performance.

Leather Piercing Needles and Their Importance

Once you’ve chosen the perfect leather sewing machine, the next step is understanding the importance of a leather sewing machine needle. The right needle is the backbone of any successful leather project, guaranteeing clean, durable stitches without damaging the material.

Unlike standard needles, leather sewing machine needles feature wedge-shaped tips, designed to cut directly through leather rather than pushing fibers aside. This prevents skipped stitches and guarantees precision.

Here’s what to remember:

- Needle Point Types: Use triangular or diamond points for smooth piercing.

- Needle Size Guide: Choose sizes like 90/14 for thin leather and 120/19 for thicker hides.

- Needle Material Impact: High-strength steel resists bending and snapping.

A good sewing machine leather needle doesn’t just protect your leather—it improves machine performance and keeps threads intact. Always pair the needle size with your leather’s thickness!

Strong and Durable Thread for Leather Sewing

Your needle is ready, but let’s talk thread—it’s the backbone of leather stitching. Picking the right leather sewing thread is key to creating durable, beautiful work that lasts.

Look for these features in thread:

- Thread Material: Bonded nylon adds strength, while polyester provides UV resistance—perfect for outdoor leather projects.

- Thread Weight: Thicker leather needs heavier thread to match its durability, guaranteeing it holds under stress.

- Waxed Coating: Waxed thread reduces friction, producing smoother stitches and helping combat wear during sewing.

Remember, leather stitching is unforgiving; each stitch counts. Investing in the right waxed thread doesn’t just improve stitch appearance, it guarantees your project survives use and time without fraying.

Adjustable Stitch Length for Thicker Leathers

Adjustable stitch length is key when sewing leather.

For thicker materials, stick to longer stitches (4-5mm) to avoid weakening the material with excessive needle holes—the perfect balance of strength and design matters here.

This Stitch Length Guide guarantees durability while making your seams look polished.

The leather thickness impacts how your sewing machine performs, but proper adjustable settings can tackle any challenge.

Pairing ideal stitch density with the right needle and thread prevents leather damage.

Aesthetic stitch choices add style, while strong feed dogs and a walking foot keep materials steady.

Master adjustable settings for seamless leather crafting!

Cylinder-Arm or Flatbed Machines for Leather Sewing

Choosing between cylinder-arm and flatbed machines depends on your leather sewing needs.

Each has unique strengths:

- Cylinder-arm benefits include reaching tight corners for bags, boots, or curved seams.

- Flatbed advantages focus on stability, ideal for flat items like wallets or belts.

Some leather sewing machines offer attachments, turning a cylinder-arm into a flatbed for versatile material handling.

For bulkier projects, industrial sewing machines cater to workspace considerations and heavier tasks.

Pick a machine that suits your project type and workspace efficiently.

Combination machines blend these strengths, offering increased project versatility.

Speed Control for Accuracy and Precision

Speed control is a game-changer for precision sewing on a leather sewing machine.

Variable speed settings let you tailor the pace for different tasks, enhancing stitch consistency and accuracy.

- Use slower speeds with the foot pedal for tight corners.

- Maintain stitch control on delicate leather for clean results.

- Opt for higher motor control on straight seams for thicker hides.

- Switch seamlessly between settings for smooth shifts.

Tips and Techniques for Sewing Leather

Sewing leather requires the right tools, careful adjustments, and a steady approach to avoid costly mistakes.

By using techniques like practicing on scraps and selecting strong thread, you’ll achieve cleaner, more professional results.

Using a Leather Needle and Strong Thread

Success in leather stitching starts with the right pairing of needle and thread.

A leather sewing machine works best with specialized leather needles, like those featuring Needle Point Types (90/14 to 110/18), designed to pierce without tearing.

Combine these with durable leather thread—waxed polyester or bonded nylon—for smoother stitching and abrasion resistance.

Thread Size Matters, so match it with your leather’s thickness and needle choice.

Tension Adjustments are key: balanced tension guarantees neat Stitch Appearance.

Using a leather needle and strong thread keeps your projects consistent, durable, and ready to handle even heavy-duty sewing needs effortlessly.

Adjusting The Tension for Leather Sewing

When sewing leather, tension adjustment is critical for clean, professional stitches.

Begin by setting your leather sewing machine tension between 3.5 and 4.5 for thick leather—this prevents slack stitches or tangles.

Always test stitching on a scrap piece first to spot issues like thread breaks or uneven knots.

Watch how bobbin tension interacts; the thread knot should sit snugly in the fabric, not above or below.

Leather thickness matters too—thicker materials need higher tension settings.

If stitching looks uneven, troubleshoot using small adjustments.

Proper threading is key to avoiding uneven stitch problems.

Slowing your speed can also boost control and precision.

Mastering sewing machine tension takes practice, so don’t rush.

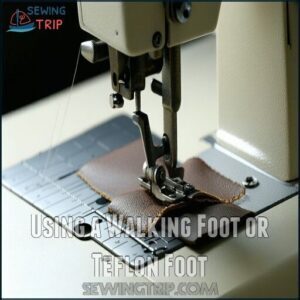

Using a Walking Foot or Teflon Foot

You’ve fine-tuned your tension, now let’s tackle feeding challenges by using the right presser foot for your leather sewing machine.

Leather can be tricky—it sticks, stretches, and refuses to move smoothly without proper tools.

That’s where a walking foot or Teflon foot steps in.

- Walking Foot Uses: Moves in sync with the feed dogs, ensuring even leather movement.

- Teflon Foot Uses: Glides over sticky leather surfaces, reducing drag.

- Foot Pressure Adjustments: Helps prevent puckering or stretching on thick leather.

- Alternative Presser Feet: Include roller feet or edge guides for precision stitching.

A walking foot is your go-to for thicker leather, offering professional results without snags.

A Teflon foot excels on delicate, sticky finishes.

Swap them out and let your projects shine!

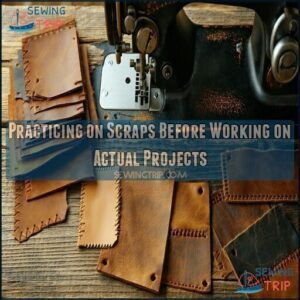

Practicing on Scraps Before Working on Actual Projects

Testing your leather sewing machine on scrap leather is a smart step that always pays off.

It’s the key to mastering stitch consistency and learning how your machine handles tension settings.

Start with small scraps to refine your technique, adjust tension, and get familiar with how leather behaves under the needle.

Gradually test seams and edges, aiming for precision and reduced errors before moving to a full project.

This approach as well improves material familiarity but also sharpens your skills for real sewing machine leather projects.

Remember, practice saves costly mistakes—consider it your secret weapon for technique refinement and flawless leather sewing results.

Maintaining and Operating Leather Sewing Machines

Keeping your leather sewing machine in top shape requires regular maintenance, proper adjustments, and a little attention to detail.

When you clean, lubricate, and follow the instructions in your machine’s manual, you’ll guarantee smooth operation and long-lasting performance.

Daily Activation and Regular Maintenance

How do you keep your leather sewing machine running like a charm? Daily care and maintenance are key to smooth operation and longevity assurance.

Here’s your must-do list:

- Clean Daily: Remove lint and dust from the bobbin case and feed dogs.

- Lubricate Often: Oil moving parts every 8 hours of use.

- Replace Needles: Swap needles after 4-8 hours to prevent skipped stitches.

- Check Tension: Adjust thread tension for every project.

- Listen Closely: Noise prevention starts with catching unusual motor sounds early.

Keep your machine running flawlessly!

Stitch Length Adjustment and Pressure Control

Getting the most out of your leather sewing machine means mastering the balance between stitch length and pressure settings.

Adjusting these settings isn’t just for pros—it’s a game-changer for consistent stitching.

For heavier leather thickness, shorter stitches (around 1.5–2mm) create durable seams, while longer ones work great for decorative flair.

Watch your presser foot pressure too. Lower it for softer leather to avoid puckering, and crank it up for heavier materials to guarantee smooth movement.

Always test these adjustable settings on scrap pieces first. It’s like warming up before a match—avoiding mishaps and guaranteeing length and precision before the real project starts.

Cleaning and Lubrication for Smooth Operation

Your leather sewing machine thrives on regular cleaning and proper lubrication. Skipping these steps? That’s a recipe for trouble! Smooth operation starts with consistent sewing machine maintenance, ensuring durable performance for all your leather projects.

Here’s how to keep your machine in top shape:

- Component Cleaning: Gently brush away lint, thread bits, and debris from feed dogs, the bobbin case, and tension discs after every project.

- Oiling Frequency: Apply the right lubricant types (machine-specific oil, not household oil) to the recommended points every 8-10 hours of use.

- Shuttle Race Care: Remove hidden lint and threads with a clean cloth to fix tension problems.

- Preventative Maintenance: Check for wear on belts, needles, and gears regularly—don’t let small issues snowball.

- Troubleshooting Issues: Inspect and address abnormal noises or uneven stitching immediately.

A well-oiled leather sewing machine guarantees flawless craftsmanship and longer life!

Referencing The Owner’s Manual for Specific Instructions

Referring to your owner’s manual is like discovering a treasure chest of essential knowledge for your leather sewing machine.

It offers a detailed troubleshooting guide, stitch settings, and safety precautions suited to your model.

Need clarity on accessory usage or your maintenance schedule? The manual has you covered.

Before contacting support, check it for solutions to common sewing machine troubleshooting issues like tension problems or needle alignment.

Following these tips guarantees smoother sewing machine operation and prolongs your machine’s life, keeping your leather projects flawless.

Frequently Asked Questions (FAQs)

What is the best leather sewing machine?

Funny how you’re here searching for the perfect leather sewing machine.

The Juki TL-2000Qi shines for pros with speed and precision, while the affordable Brother ST371HD suits beginners tackling lighter leather projects.

How to choose the best sewing machine for leather?

Choose a leather sewing machine by considering leather thickness, motor strength, stitch options, and features like walking feet or adjustable presser pressure.

Prioritize durability, speed control, and your project needs for the best results.

What is the best heavy duty sewing machine?

Power, precision, durability—these define the Juki TL-2000Qi.

It’s perfect for heavy-duty tasks, offering 1,500 stitches per minute, a sturdy metal frame, and unmatched reliability to tackle thick materials with ease and confidence.

Which sewing machine should I buy?

Look for a sewing machine that matches your needs—choose heavy-duty models like the Singer 4423 for versatility.

Consider features, budget, and expected usage, or industrial options like the Juki DU-1181N for complex leather projects.

What is the best sewing machine for leather?

If you’re sewing leather, the Juki DU-1181N is exceptional.

It’s industrial, handles thick leather with ease, and uses top and bottom feed technology for precision.

For smaller projects, consider the Singer 4423.

What is the difference between a sewing machine and a leather sewing machine?

In the context of sewing machines, leather sewing models are the real workhorses.

They boast stronger motors, specialized needles, tougher feed mechanisms, and sturdy frames, making them perfect for thick, durable materials regular machines can’t handle.

What Singer sewing machine will sew leather?

The Singer 4423 and Singer 4432 are great for sewing leather.

They offer high-speed stitching, heavy-duty build, and strong motors to handle thicker fabrics, making them reliable choices for leather projects at home.

How thick of leather can a sewing machine sew?

Did you know some machines handle up to 1" thick leather.

Industrial models excel here, offering powerful motors and larger needles.

For lighter leather, domestic machines work with adjustments like proper needles and presser feet.

Is it better to sew leather by hand or machine?

It depends on your project.

Machines handle thick leather faster and with precision, ideal for bigger tasks.

Hand-sewing offers control and durability, making it perfect for detailed work or when precision matters most.

Which Juki is best for leather?

Ironically, not all Juki models excel at leather, but the Juki DU-1181N shines.

With top-bottom feed technology, a servo motor, and power to handle thick materials, it’s your leather sewing powerhouse.

Conclusion

Imagine you’re crafting a handmade leather bag but your machine struggles with the thick material—it’s time for the best leather sewing machine.

Picking the right one, like the Singer Heavy Duty 4452 for power or the Janome HD3000 for versatility, guarantees smooth sewing every time.

Focus on key features like a strong motor, walking foot, and leather-piercing needles.

With the right machine, your leather projects will be precise, durable, and frustration-free.

Choose wisely, and start creating!