This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Look for durable, high-speed motors that handle various fabrics, from delicate chiffon to tough denim, without skipping a beat.

Programmable stitch patterns, adjustable presser foot pressure, and an automatic thread cutter save time while improving consistency.

Machines with servo motors run quieter and use less energy, ideal for long workdays.

Sturdy metal frames guarantee stability, even at top speeds, while ergonomic designs reduce strain during use.

Don’t overlook easy maintenance features like accessible oiling points and self-lubricating parts.

Want smoother production and better results? The right features make all the difference.

Table Of Contents

- Key Takeaways

- Choosing The Right Industrial Sewing Machine

- Top 9 Industrial Sewing Machines

- 1. Janome High Speed Quilting Machine

- 2. Brother Computerized Sewing Machine

- 3. Janome Blue Couture Sewing Machine

- 4. Janome Horizon Memory Craft 9850 Sewing Machine

- 5. Brother CS7000X Sewing and Quilting Machine

- 6. Juki TL 2000Qi Sewing Quilting Machine

- 7. Singer 9960 Sewing Quilting Machine

- 8. Brother SE600 Embroidery Sewing Machine

- 9. Brother HC1850 Sewing Quilting Machine

- What Makes an Industrial Sewing Machine Better

- Features to Look for in an Industrial Sewing Machine

- Benefits of Industrial Sewing Machines

- Industrial Sewing Machine Motors and Maintenance

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Focus on features like servo motors, automated thread cutters, and adjustable presser foot pressure to save time and improve efficiency.

- Prioritize durable metal frames and high-speed stitching for handling tough fabrics and ensuring reliability.

- Choose models with large workspaces and stitch customization options for flexibility across projects.

- Regular maintenance, such as cleaning lint and oiling moving parts, extends the machine’s lifespan and keeps it running smoothly.

Choosing The Right Industrial Sewing Machine

Choosing the right industrial sewing machine means balancing your specific project needs with the machine’s capabilities, like speed, durability, and fabric compatibility.

Balance your project needs with machine capabilities—speed, durability, and fabric compatibility ensure professional results every time.

You’ll want to verify factors such as workspace, stitch requirements, and motor efficiency to guarantee it meets both your performance and budget expectations.

Domestic Vs. Industrial Sewing Machines

Choosing between an industrial sewing machine and a domestic one boils down to your needs.

Industrial models are like workhorses—designed for power, speed, and longevity. They handle heavy-duty fabrics like leather or canvas effortlessly, making them ideal for commercial sewing.

Domestic machines, on the other hand, are better for occasional, lightweight projects.

- Power Requirements: Industrial machines boast 550-1,100 watts vs. 70-100 watts in domestic models.

- Material Thickness: Easily stitches multiple denim layers or thick leather.

- Stitch Variety: Consistent, professional-grade results.

- Intended Lifespan: Built for 24/7 operation.

Key Features to Consider

If you’re upgrading to an industrial sewing machine, focus on the features that make sewing faster, smoother, and more precise.

Focus on features that enhance speed, precision, and smooth operation for an unparalleled sewing experience with your industrial machine.

High-speed stitching—up to 5,000 stitches per minute—keeps productivity on point. Look for stitch customization options like adjustable stitch length for flexibility across projects.

Durable metal frames guarantee your machine can handle long hours without breaking a sweat. Large bobbin capacity minimizes interruptions, while automation features like automatic needle threaders save time.

Prioritize motor efficiency with servo motors for quieter, energy-saving performance. Don’t overlook workspace accessories like extension tables for bulkier materials.

Trusted brand reputation guarantees reliability, making your investment worthwhile.

Budget and Space Constraints

When picking an industrial sewing machine, your budget and available space play a big role. Thankfully, compact models pack professional-grade power without hogging your workspace. Machines like the Juki DDL-900C are space-saving champions, offering full functionality with up to 30% smaller footprints.

Entry-level machines, starting at $800, provide excellent quality options under $1,500, making them great for tight sewing machine budgets. Don’t forget to account for your workspace setup—factor in the machine’s size, material clearance, and your movement needs. These machines often include automatic thread cutting for improved efficiency.

- Compact models: Perfect for small studios, delivering top performance.

- Entry-level machines: Affordable yet powerful, ideal for beginners.

- Workspace setup: Make certain you have enough room for materials and comfortable operation.

Type of Fabric and Stitch Requirements

When you’re considering industrial sewing machine features, matching the machine to your fabric types and stitch requirements is key.

Fabric weight dictates your setup: light knits need zigzag stitches with fine polyester thread, while heavy-duty fabrics like canvas thrive on triple stitches and upholstery thread.

Stitch density and seam strength also matter. For denim, use a #16 needle with longer stitches to handle thickness and maintain durability. Delicate fabrics like silk? Opt for a #9 needle and tighter stitches for precision.

Thread compatibility plays a big role too—bonded nylon for leather or heavy-duty nylon for thicker materials. Adjusting needle selection and stitch types guarantees your machine handles every project with professional-grade results.

Top 9 Industrial Sewing Machines

When you’re searching for the best industrial sewing machines, it’s essential to find models that combine speed, durability, and precision.

We’ve compiled a list of nine top-performing options, each designed to handle demanding projects with ease and reliability.

1. Janome High Speed Quilting Machine

The Janome 1600P-QC is a quilting workhorse, blending industrial strength with precise craftsmanship. At lightning-fast speeds of 1,600 stitches per minute, it’s perfect for tackling large, intricate projects without breaking a sweat.

You’ll love its nearly 9" x 6" workspace, offering ample room for bulky quilts or layered fabrics. The automatic thread cutter is a time-saver, seamlessly trimming threads between sections, while the speed control slider facilitates smooth shifts from delicate stitching to high-speed runs.

Its industrial pretension threading guarantees consistent tension, critical for professional-grade results. Many users appreciate the 25-year limited warranty that comes standard with Janome machines.

The ergonomic knee lift frees your hands for better fabric control, making it easier to handle detailed work. While the side-loading bobbin may take some getting used to, its independent motor for bobbin winding adds convenience. For serious quilters, this machine is a reliable partner that delivers speed and precision.

Best For: Serious quilters and sewing enthusiasts who need a high-speed, straight-stitch-only machine with ample workspace for large projects.

- Small side-loading bobbin requires frequent changes and can be tricky to set up.

- Reports of light malfunction and occasional operational issues.

- Limited customer support access with frustration over toll-free service.

- Extremely fast stitching at 1,600 stitches per minute for efficient work.

- Large 9" x 6" workspace accommodates bulky or layered projects.

- Independent motor for bobbin winding without pausing sewing.

2. Brother Computerized Sewing Machine

Why settle for less when the Brother XR9550 offers industrial-grade performance with a user-friendly touch? This computerized sewing machine boasts 165 built-in stitches, including 8 auto-size buttonholes, ensuring you’ll always find the perfect design for your project.

Its intuitive LCD screen makes stitch selection a breeze, saving you time and frustration. From delicate silks to sturdy denim, the XR9550 handles a wide range of fabrics with consistent precision.

The automatic needle threader, while a bit tricky at first, quickly becomes a time-saver once mastered. Plus, the jam-resistant drop-in top bobbin keeps your workflow smooth.

Need more workspace? The included wide table is perfect for quilting or sewing larger garments, while 8 quick-change presser feet let you switch techniques effortlessly. Whether you’re crafting heirlooms or tackling heavy-duty projects, this machine combines versatility, speed, and reliability to meet your sewing needs.

Best For: Beginners to intermediate sewists looking for a versatile and user-friendly sewing machine with advanced features for sewing, quilting, and crafting.

- Automatic needle threader can be inconsistent and challenging to use.

- Designed exclusively for 120-volt use in the US, limiting international compatibility.

- Long-term reliability of advanced features varies based on user feedback.

- Offers 165 built-in stitches, including 8 auto-size buttonholes and alphanumeric options for personalization.

- Wide table and 8 presser feet included for enhanced versatility and quilting projects.

- Intuitive LCD screen simplifies stitch selection and machine settings.

3. Janome Blue Couture Sewing Machine

If you’re after a dependable, budget-friendly sewing machine, the Janome Blue Couture might be your perfect match.

With 15 built-in stitches and an easy-to-use front-loading bobbin system, it’s designed for smooth, hassle-free operation.

The heavy-duty metal frame guarantees durability, while the 3-piece feed dog system handles fabrics effortlessly.

Ideal for beginners, it excels at everyday projects but isn’t suited for heavy upholstery.

Features like adjustable tension, a removable free arm, and specialized presser feet make it versatile for cuffs, zippers, and hems.

Best For: Beginners or budget-conscious sewists looking for a durable and versatile machine for everyday sewing projects.

- Not suitable for heavy-duty upholstery sewing.

- Limited to basic mechanical functions without advanced automation.

- Front-loading bobbin system might not appeal to those preferring top-loading designs.

- Durable heavy-duty metal frame for long-term reliability.

- Beginner-friendly with 15 built-in stitches and easy controls.

- Versatile features like adjustable tension and removable free arm.

4. Janome Horizon Memory Craft 9850 Sewing Machine

The Horizon Memory Craft 9850 is a dream machine for sewing enthusiasts who want both precision and versatility.

Packed with 200 built-in stitches and 175 embroidery designs, it handles everything from intricate embroidery to professional-grade sewing projects. Its top speed of 1,000 stitches per minute guarantees you’ll breeze through even the most detailed tasks.

The 6.7" x 7.9" embroidery area offers plenty of space for creative designs, while the LCD touchscreen simplifies operation. Thanks to the 7-piece feed dog system, fabrics glide smoothly, no matter their type.

Built to last with durable construction, it’s perfect for small business owners or serious hobbyists. Key highlights include a top-loading rotary hook for jam-free sewing and customizable settings for personalized results. The machine’s ability to provide professional-grade sewing projects makes it a valuable asset.

Best For: Intermediate to experienced sewing enthusiasts and small business owners looking for both versatile sewing and embroidery capabilities.

- Heavy machine, limiting portability.

- Limited built-in embroidery designs compared to other models.

- Requires proprietary accessories that can be costly.

- Combines sewing and embroidery functions in one machine.

- Offers smooth, quiet operation with precise stitching options.

- USB compatibility for custom embroidery designs.

5. Brother CS7000X Sewing and Quilting Machine

The Brother CS7000X Sewing and Quilting Machine is a versatile gem, perfect for tackling a wide range of sewing projects.

With 750 stitches per minute, it’s fast enough to breeze through tasks while maintaining precision. The automatic needle threader and jam-resistant drop-in bobbin system make setup and sewing frustration-free, saving you valuable time.

You’ll love the 70 built-in stitches, offering plenty of creative options for both decorative and functional sewing. The detachable wide table provides ample space for larger quilting projects, ensuring smooth maneuverability.

Its sturdy metal frame guarantees durability, even with regular use. Navigating settings is simple with the clear LCD display, while the machine handles everything from delicate fabrics to thicker layers with consistent, professional-grade stitch quality.

Best For: Sewing enthusiasts, hobbyists, and professionals looking for a budget-friendly machine with features ideal for both quilting and everyday sewing projects.

- Some plastic components may raise durability concerns.

- Lacks advanced embroidery capabilities.

- Electronic parts may limit long-term reliability.

- 70 built-in stitches for creative versatility.

- Wide table and quilting-friendly features.

- Durable metal frame ensures stability.

6. Juki TL 2000Qi Sewing Quilting Machine

The Juki TL-2000Qi is a game-changer for quilters and sewists craving industrial-level performance in a compact machine.

With a blazing speed of 1,500 stitches per minute, it’s perfect for tackling everything from delicate fabrics to thick quilt layers with precision and ease.

Key features include:

- Aluminum Die-Cast Construction: Keeps vibrations low for smooth, quiet sewing.

- Large Work Area: Expandable up to 23 inches with the included extension table, ideal for larger projects.

- Knee Lifter: Allows hands-free presser foot control, boosting efficiency.

- Automatic Thread Cutter: Saves time by trimming threads with the press of a button.

While it’s not a beginner’s machine, its straight-stitch focus guarantees flawless results for serious projects.

If you’re after durability and professional-grade stitching, the TL-2000Qi is worth every penny.

Best For: Quilters and sewists seeking a high-speed, heavy-duty machine for professional-level straight stitching and handling diverse fabrics with precision.

- Steep learning curve for optimal use and adjustments.

- Limited to straight stitching with no decorative stitch options.

- Electronic components may raise long-term reliability concerns.

- 1500 stitches per minute for fast and efficient sewing.

- Durable aluminum die-cast construction reduces vibration for smooth operation.

- Wide work area with extension table for large projects.

7. Singer 9960 Sewing Quilting Machine

The Singer 9960 is a feature-packed powerhouse, perfect for hobbyists and semi-professionals seeking versatility and precision.

While it’s not a full-fledged industrial machine, its 600 built-in stitches and 1,172 stitch applications offer incredible customization through an easy-to-navigate LCD screen. With a sewing speed of 850 stitches per minute, it’s ideal for home projects, though it won’t match the lightning-fast pace of industrial models.

Its sturdy metal frame guarantees stability, while weighing just 18.2 pounds for portability—a rare combination.

Time-saving features like the automatic needle threader and top drop-in bobbin system make setup a breeze. Quilters will appreciate the included extension table, expanding workspace for larger projects.

However, for heavy-duty fabrics like leather or multiple denim layers, this machine might struggle where industrial-grade options excel. It’s a reliable choice for most creative sewing needs.

Best For: Hobbyists and semi-professionals looking for a versatile and feature-rich sewing machine for general sewing and creative projects.

- Offers 600 built-in stitches and 1,172 stitch applications for high customization.

- Time-saving features like an automatic needle threader and top drop-in bobbin.

- Lightweight and portable with a sturdy metal frame for stability.

- Struggles with heavy-duty fabrics like leather or thick denim.

- Issues with quilting capabilities, including incompatibility of the quilting bar and walking foot.

- Problems with bobbin winding and removal require extra manual effort.

8. Brother SE600 Embroidery Sewing Machine

The SE600 bridges functionality and creativity, making it a standout choice for embroidery enthusiasts and small-scale projects.

With a speed of 710 stitches per minute, it keeps your workflow efficient while offering 80 built-in embroidery designs and 6 lettering fonts to foster your artistic side.

The automatic needle threader saves time and frustration, and the jam-resistant drop-in bobbin system guarantees smooth operation without interruptions.

Its 3.2" LCD color touchscreen makes design selection and editing intuitive, letting you preview and adjust with ease.

However, the 4"x4" embroidery area and plastic components limit it for heavy-duty or high-volume use.

Ideal for home-based businesses or hobbyists, this machine delivers versatility and precision, but it’s best suited for lighter workloads rather than industrial demands.

Best For: Home-based businesses or hobbyists looking for a versatile, user-friendly sewing and embroidery machine for light to medium workloads.

- Includes 80 built-in designs and 6 embroidery fonts for creative versatility.

- 3.2" LCD touchscreen enables real-time design preview and editing.

- Automatic needle threader and jam-resistant features enhance ease of use.

- Limited 4"x4" embroidery area restricts capacity for larger designs.

- Plastic components may not withstand heavy-duty use over time.

- Lacks features suitable for high-volume or industrial projects.

9. Brother HC1850 Sewing Quilting Machine

Balancing versatility and user-friendliness, the Brother HC1850 is a sewing and quilting machine designed for creative enthusiasts and small-scale projects.

With 185 built-in stitches, including 55 alphanumeric options, it’s perfect for tackling diverse sewing tasks. The backlit LCD screen simplifies stitch selection, while the jam-resistant drop-in top bobbin guarantees smooth operation.

Lightweight yet reliable, this machine includes a spring action quilting foot, making it ideal for quilting or general sewing at home. While not industrial-grade, its adjustable speed control and wide table accommodate larger projects.

If you’re a hobbyist or running a home-based business, the HC1850 offers quality results without overwhelming complexity or cost.

Best For: Hobbyists and small business owners seeking a versatile, user-friendly sewing and quilting machine for home projects.

- 185 built-in stitches, including 55 alphanumeric stitches for creative designs.

- Lightweight and portable, making it easy to transport and set up.

- Includes a wide table and quilting foot for larger quilting projects.

- Needle threader can be challenging to use.

- Work light is dim, making detailed work harder in low-light conditions.

- Power cord may feel loose or unstable during use.

What Makes an Industrial Sewing Machine Better

You’ll find that industrial sewing machines stand out with their unmatched durability, speed, and ability to handle heavy fabrics with ease.

They’re built for precision and efficiency, making them indispensable for high-volume or specialized sewing tasks.

Durability and Strength

Durability is the backbone of any industrial sewing machine, giving you the confidence to tackle heavy-duty sewing projects with ease. These machines are built to last, featuring metal frames and all-metal internal components designed for continuous operation.

Here’s what sets their unrivaled durability apart:

- Stress-tested parts guarantee an extended component lifespan, even under daily use.

- Sturdy construction minimizes vibration, maintaining stitch consistency on heavy fabrics like leather or denim.

- Industrial-strength builds handle multiple layers effortlessly, excelling where domestic machines falter.

With these industrial sewing machine features, you’ll enjoy years of reliable performance without compromise.

Speed and Efficiency

Maximizing speed and efficiency with an industrial sewing machine is a game-changer for productivity.

These machines excel with SPM optimization, reaching up to 5,500 stitches per minute, allowing you to complete projects in record time without compromising quality.

Here’s how they boost your workflow:

- High-speed motors: Servo motors guarantee energy efficiency and precise speed control.

- Automation benefits: Features like automatic thread cutters and large bobbin capacities minimize downtime.

- Batch sewing capabilities: Handle multiple layers effortlessly with advanced fabric feed systems.

- Ergonomic impact: Adjustable speed controls reduce strain, letting you work longer comfortably.

Whether tackling commercial orders or detailed projects, these machines streamline operations.

Workflow analysis shows they cut production time by up to 70%, guaranteeing consistent, professional-grade results every time.

Specialization and Programmability

With modern industrial sewing machine features, specialization and programmability elevate your craft.

Machines designed for specific tasks—like pocket setters or double-needle units—deliver precision and speed.

Programmable patterns and software integration let you save settings for repeat projects, while fabric sensors guarantee flawless stitching on various materials.

Custom stitching and pattern memory simplify intricate designs, reducing errors, and computerized sewing technology, including automated functions like thread cutters, transforms workflow, making complex projects faster and more efficient.

Automatic Features and Upgrades

Automation in industrial sewing machines takes efficiency to the next level, offering precision and ease. With features like automatic thread cutters, you’ll skip the hassle of manual snipping. Programmable patterns let you store designs for flawless repetition, while automatic lubrication guarantees smooth operation without constant maintenance.

Here’s how sewing machine automatic features simplify your work:

- Needle Threaders and auto-trimmers save time on tedious tasks.

- Servo motors and automated presser feet improve control on complex fabrics.

- Programmable patterns and thread trimming boost productivity for intricate projects.

These upgrades streamline production and elevate stitch quality.

Features to Look for in an Industrial Sewing Machine

When choosing an industrial sewing machine, you’ll want to focus on features that guarantee durability, precision, and ease of use.

From sturdy construction to user-friendly controls, these details directly impact performance and long-term value.

Serviceability and Maintenance

Keeping your industrial sewing machine in top shape isn’t rocket science, but it does demand attention. Machines with accessible components simplify routine inspections and oiling procedures, saving time and frustration. Look for models with detailed troubleshooting guides and easy-to-remove parts like bobbins and tension units.

Here’s a quick comparison to examine:

| Feature | Benefit | Example |

|---|---|---|

| Preventative Maintenance | Reduces repair costs | Regular cleaning and oiling |

| Part Replacement | Faster repairs | Easily sourced screws and needles |

| Sewing Machine Cleaning Frequency | Ensures smooth operation | Weekly for heavy use |

Investing in sewing machine serviceability pays off with fewer breakdowns and smoother operation. Regular maintenance can extend the life of your machine, and you can find products for upkeep online.

Durable Construction and Materials

Durability is the heart of any industrial sewing machine, guaranteeing it withstands demanding tasks and heavy fabrics. A metal frame is non-negotiable, offering unmatched stability and vibration reduction for smoother operation.

To guarantee your machine lasts, focus on these key features:

- Metal Frames: Cast iron or aluminum alloy frames resist material fatigue, providing a solid foundation for heavyduty sewing.

- Hardened Components: Steel gears and shafts extend component lifespan, even under intense pressure.

- Robust Construction: Heavy-duty designs handle thick materials like canvas and leather effortlessly.

For handling thicker materials, consider a machine with sufficient motor strength. Investing in such durable construction guarantees reliability and minimizes downtime, making your machine a workhorse for years.

Usability and Ergonomics

Operator comfort isn’t just a perk—it’s essential for reduced fatigue and long-term productivity.

When evaluating sewing machine ergonomics, focus on features that make your workspace user-friendly and efficient.

- Adjustable Table Height: Prevent strain by customizing your workspace design to fit your posture.

- Intuitive Controls: Simplify the sewing machine learning curve with easy-to-reach, accessible features.

- Built-in LED Lighting: Enhance sewing machine ease of use by eliminating shadows for precise stitching.

A well-designed sewing machine workspace guarantees ease of use, keeping you focused and efficient.

Price and Value for Money

When evaluating industrial sewing machines, focus on the balance between sewing machine price and value. An initial investment of $500–$5,000 may seem steep, but feature justification is key for long-term savings.

Entry-level machines ($500–$1,000) suit beginners, while mid-range options ($1,000–$2,500) offer durability and servo motors. Professional models ($2,500+) deliver automation, advanced features, and unmatched longevity.

Compare brands carefully—brand reputation often reflects reliability and ROI analysis. Look for metal frames, powerful motors, and specialized feet, as these features enhance durability and productivity.

Spending more upfront often reduces repair costs, proving that true sewing machine value lies in thoughtful selection. For diverse needs, consider a machine with automatic thread trimming to enhance user experience.

Benefits of Industrial Sewing Machines

You’ll find industrial sewing machines invaluable for tackling demanding projects with unmatched speed and precision.

Their robust construction and advanced features guarantee consistent results, reduced downtime, and enhanced efficiency for both small-scale and large-scale production.

Increased Productivity and Efficiency

Boosting your output starts with the right industrial sewing machine features.

These machines elevate productivity with remarkable speed, reaching up to 5,500 stitches per minute, far outpacing domestic options.

Plus, automation benefits like automatic thread cutters and needle threaders streamline your workflow, making tedious tasks a breeze.

- High-Speed Stitching: Complete projects faster without sacrificing precision.

- Ergonomic Design: Large bobbins mean fewer interruptions, keeping you in the zone.

- Reduced Downtime: Servo motors guarantee consistent performance, powering an optimized workflow.

With these tools, efficiency becomes second nature.

Improved Stitch Quality and Consistency

When productivity meets precision, stitch quality becomes the hallmark of industrial sewing machines.

With advanced Tension Control and optimized Feed Mechanisms, you’ll achieve impeccable stitching quality that stands out.

These machines excel in Needle Precision, guaranteeing every stitch lands exactly where it should, even on challenging materials.

Their Vibration Reduction design keeps the process smooth, while enhanced Material Handling guarantees consistent results across layers and fabric types.

Say goodbye to puckering and uneven seams—your projects will have a professional, polished look.

| Feature | Benefit |

|---|---|

| Tension Control | Eliminates puckering |

| Feed Mechanisms | Ensures even stitching |

| Needle Precision | Perfect stitch placement |

| Vibration Reduction | Smooth operation |

| Material Handling | Works with tough fabrics |

This level of stitch consistency transforms homemade into high-end.

Reduced Maintenance and Repair Costs

Regarding industrial sewing machines, reducing repair costs is all about smart design and proactive care.

By focusing on Preventative Maintenance, you’ll keep your machine humming along and avoid costly downtime.

Here’s how these machines save you money:

- Automatic oiling systems guarantee proper sewing machine lubrication, covering important sewing machine oiling points without constant oversight.

- Durable components extend the lifespan of parts, minimizing frequent replacements.

- Repair accessibility simplifies sewing machine repair, with easy-to-reach parts and straightforward fixes.

- Cost-effective upgrades allow enhancements without breaking the bank.

A well-maintained machine reduces sewing machine repair costs, boosts Component Lifespan, and keeps your operations running smoothly.

Enhanced Creativity and Customization

After cutting repair costs, it’s time to tap into your creative side.

Industrial sewing machines empower your projects with unmatched precision and flair.

- Sewing machine programmable designs allow you to craft personalized patterns and intricate thread painting effortlessly.

- Fabric manipulation tools and attachments support appliqué techniques and other creative embellishments.

- Hundreds of sewing machine decorative stitches, combined with custom embroidery options, elevate your designs.

These features turn sewing machine customization into a seamless way to bring your creative vision alive.

Industrial Sewing Machine Motors and Maintenance

Understanding your sewing machine’s motor and its upkeep is vital for maintaining efficiency and extending its lifespan.

Whether you’re comparing clutch motors to servo motors or planning regular cleaning and oiling, proper maintenance guarantees consistent performance and fewer costly repairs.

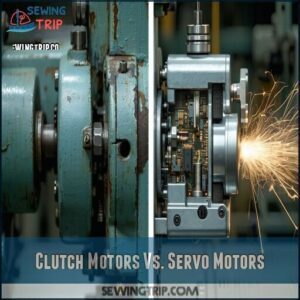

Clutch Motors Vs. Servo Motors

Choosing between a clutch motor and a servo motor impacts your sewing machine’s performance and your energy bills.

Clutch motors are reliable workhorses but run continuously, creating more noise and higher energy consumption. In contrast, servo motors only operate when you press the pedal, offering quieter operation and up to 70% energy savings.

With variable speed control (400–4000 RPM), servo motors excel in precision tasks, while clutch motors provide steady torque for heavy-duty jobs.

Consider your industrial sewing machine features, like noise levels, energy consumption, and motor lifespan, to pick the right sewing machine motor type. Many retailers offer sewing machine motors for various needs.

Maintenance and Repair Requirements

Preventative maintenance keeps your industrial sewing machine running smoothly and avoids costly downtime.

Follow this servicing schedule:

- Daily cleaning: Remove lint from feed dogs and bobbin areas after each use.

- Weekly lubrication: Use the correct sewing machine oil type for moving parts.

- Monthly inspections: Check needle condition, belt tension, and sewing machine parts for wear.

- Seasonal troubleshooting: Refer to a troubleshooting guide for unusual noises or performance issues.

Routine care minimizes common repairs and extends machine life.

Upgrading and Replacing Motors

Old sewing machine motors can hold you back, but upgrading solves many hassles.

Switching from a clutch motor to a servo motor dramatically improves your machine’s performance.

Servo motors provide precise speed control, run quietly, and consume 71% less energy compared to clutch motors.

For anyone tackling heavy fabrics or detailed work, this upgrade means smoother, more efficient operation.

You can enhance your sewing setup with a servo motor upgrade.

| Motor Comparison | Clutch Motor | Servo Motor |

|---|---|---|

| Energy Usage | High | Low |

| Speed Control | Limited | Accurate |

| Noise Level | Loud | Quiet |

| Vibration | Heavy | Minimal |

| Lifespan | Moderate | Longer |

Servo motor benefits also extend to installation ease, with most replacements fitting existing setups.

When considering sewing machine motor replacement, reliable options like the Sailrite Workhorse or Consew CSM 550-1 guarantee seamless upgrades.

Importance of Regular Cleaning and Oiling

Upgrading your sewing machine motor is just the start; keeping it running smoothly takes care. Regular cleaning and oiling prevent wear, extend lifespan, and help troubleshoot issues before they worsen.

Here’s how to master sewing machine maintenance through cleaning and oiling:

- Use proper oil types like synthetic oil for high-speed industrial units.

- Stick to a set cleaning frequency—remove lint daily, especially from feed dogs and bobbin areas.

- Know your machine’s oiling points—typically around friction-heavy moving parts.

To maintain stitch quality, remember to address sewing machine oiling. Enjoy the long-term benefits of preventative maintenance!

Frequently Asked Questions (FAQs)

What makes an industrial sewing machine better?

An industrial sewing machine outshines regular models with its superior speed, durability, and precise stitching.

It handles tough fabrics like leather or denim effortlessly, operates continuously for hours, and includes advanced features like automatic threaders.

How do I choose an industrial sewing machine?

Choose by matching the machine to your project needs.

Consider fabric type, motor power, speed, and features like stitch customization.

Prioritize reputable brands, durability, and workspace requirements.

Test it if possible before committing.

Which is better Jack or Juki?

Both Jack and Juki are reliable, but Juki’s renowned for unmatched durability and precision, perfect for heavy use.

Jack machines, while cost-effective, excel for beginners and medium projects.

Consider your budget, fabric types, and workload needs, including precision.

What is the difference between industrial and heavy duty sewing machines?

They say, "the right tool makes all the difference."

Industrial machines are powerhouses, built for nonstop operation and tough fabrics.

Heavy-duty machines handle thick materials too, but with less speed, power, and specialization.

How to choose an industrial sewing machine?

Focus on fabric types, motor power, and stitch speeds.

Match machine features like stitch length, presser foot lift, and thread capacity to your projects.

Prioritize reputable brands, ensuring durability, workspace compatibility, and maintenance ease.

What are the advantages of industrial sewing machines?

Industrial sewing machines offer unmatched speed, durability, and precision.

You’ll tackle heavy fabrics, multiple layers, and complex projects effortlessly.

Their reliability saves time, while advanced features like automatic threading guarantee high-quality, professional results with every stitch.

Which product is the best industrial sewing machine?

The Juki DDL-8700 stands out as the best industrial sewing machine for commercial use, offering high-speed performance, durable construction, and precise stitching.

It’s perfect for handling various fabrics while ensuring reliability during long production runs.

What features should I look for in a sewing machine?

Look for adjustable stitch length, durable metal frames, and a powerful motor.

Prioritize a quiet servo motor, compatibility with tough fabrics, and automation features like needle threaders.

Verify that workspace size matches your sewing needs.

How to know a good industrial sewing machine?

A good industrial sewing machine offers high-speed stitching, precise tension control, durable metal construction, and efficient motors.

It should handle heavy fabrics effortlessly, provide adjustable features like stitch length, and suit your project’s unique needs, making it a versatile tool with durable metal construction.

Which of the industrial sewing machines is the best?

The Juki DDL-8700 stands out as the best for commercial use, combining high-speed stitching, precise tension control, and durability.

It’s perfect for handling various materials while delivering professional-grade results, even during long production runs.

Conclusion

Selecting the right industrial sewing machine is like choosing the perfect tool for a masterpiece—it defines the quality and efficiency of your work.

By focusing on the best industrial sewing machine features, such as programmable patterns, durable construction, and energy-saving servo motors, you’ll streamline production while ensuring precision and reliability.

Prioritize functionality, ease of maintenance, and adaptability to fabrics.

With the right machine, you’ll boost productivity, elevate results, and enjoy smoother operations for years to come.

- https://www.sewingmachinesplus.com/sewing-machines-reliable-2000u33.php

- https://thecraftyneedle.com/sewing/machines/best-industrial-sewing-machine/

- https://sewingmachineman.substack.com/p/industrial-sewing-machines-pros-and

- https://www.nytimes.com/wirecutter/reviews/best-sewing-machine/

- https://www.goldstartool.com/juki-sewing-machines/